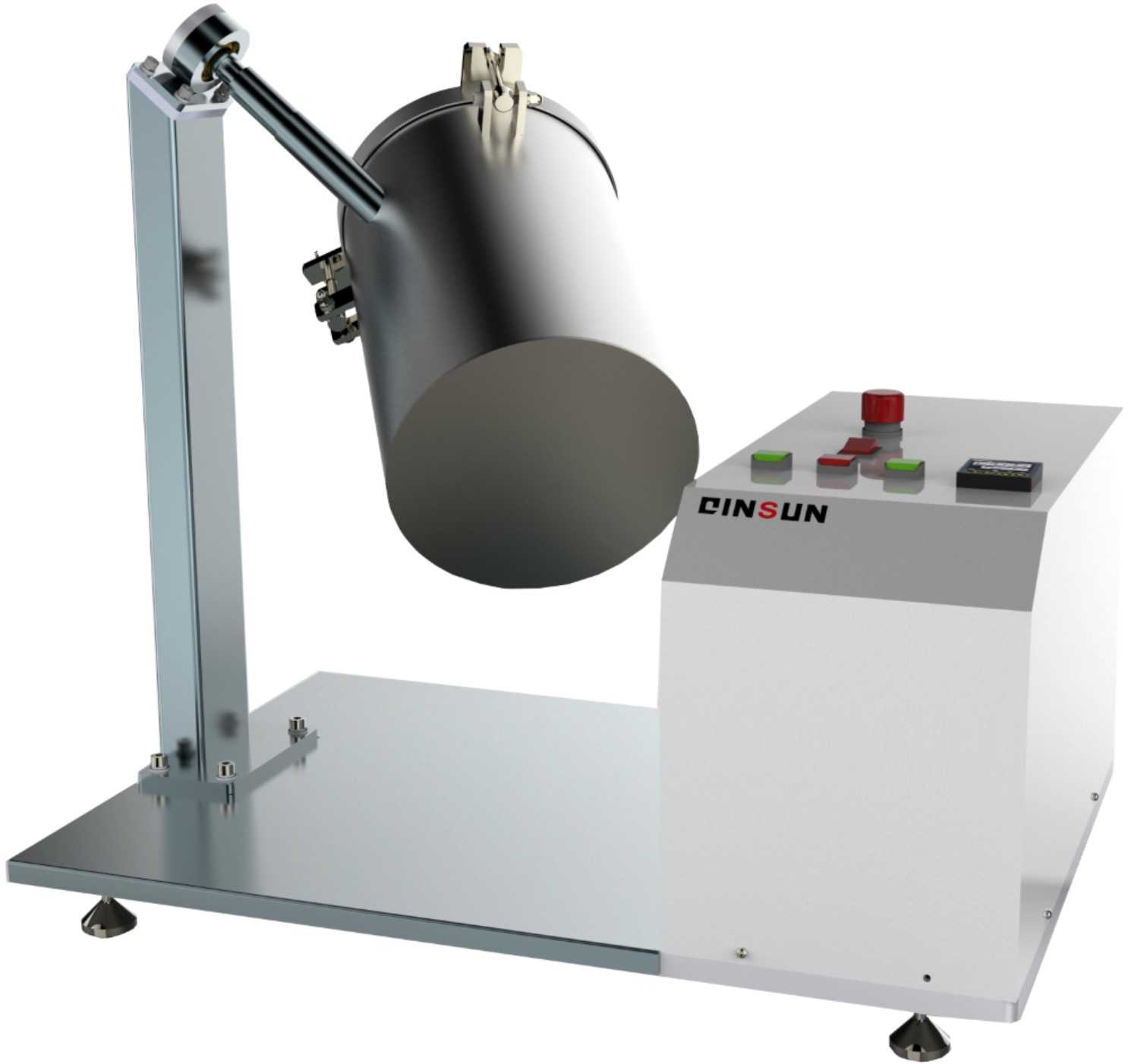

Dry Cleaning & Washing Cylinder

Introduction

The dry cleaning and washing cylinder consists of a stainless steel rotary test chamber and a multi-speed drive with a digital timer.

It is used to test the color fastness for the dry cleaning and chlorine water washing fabrics.

Application

Dry cleaning and washing cylinder is designed to determine the color fastness for the dry cleaning and chlorinated pool water, with the aim to prepare samples for flammability testing.

Standards

AATCC 162 Colorfastness to water: Chlorinated pool.

16CFR PART 1610 Standard for the flammability of clothing textiles.

● 51 ml of the hardness concentrate was diluted to 5100 ml with distilled or deionized water.

● If necessary, adjust the pH of the solution to 7.0 with sodium carbonate or acetic acid.

● 5000 ml of the solution (made in the above 3) was charged into a dry-cleaning cylinder. The temperature was adjusted to 21 ° C.

● Put the color test sample with the standard test fiber into the cylinder, turn off the barrel, and roll for 60 minutes.

● Get out the sample and remove the excess solution.

The dry cleaning and washing cylinder consists of a stainless steel rotary test chamber and a multi-speed drive with a digital timer.

It is used to test the color fastness for the dry cleaning and chlorine water washing fabrics.

Application

Dry cleaning and washing cylinder is designed to determine the color fastness for the dry cleaning and chlorinated pool water, with the aim to prepare samples for flammability testing.

Standards

AATCC 162 Colorfastness to water: Chlorinated pool.

16CFR PART 1610 Standard for the flammability of clothing textiles.

Operation

● Clean the dry cleaning cylinder

● prepare the hardness concentrates according to the relevant standards.● Clean the dry cleaning cylinder

● 51 ml of the hardness concentrate was diluted to 5100 ml with distilled or deionized water.

● If necessary, adjust the pH of the solution to 7.0 with sodium carbonate or acetic acid.

● 5000 ml of the solution (made in the above 3) was charged into a dry-cleaning cylinder. The temperature was adjusted to 21 ° C.

● Put the color test sample with the standard test fiber into the cylinder, turn off the barrel, and roll for 60 minutes.

● Get out the sample and remove the excess solution.

Technical Parameters

| Items | Parameters |

| Dimension | 72L X 49W X 62H (cm) |

| Structure | Stainless steel |

| Surface treatment | Wiredrawing treatment |

| Transport weight | 80kg |

| Power supply | 220V 50HZ max.0.05A |

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price