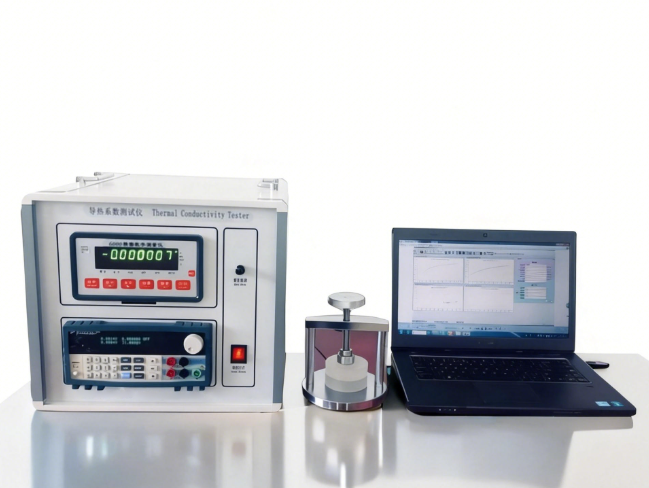

Thermal Conductivity Tester for Silicone and Ceramic Substrates

Thermal Conductivity Tester for Silicone and Ceramic Substrates is a high-precision instrument designed to measure thermal resistance, thermal conductivity, and interface contact thermal resistance of thin heat conductors, solid electrical insulation materials, thermal grease, resins, rubber, beryllium oxide ceramics, and aluminum oxide ceramics. The instrument can test solid sheet materials directly, and with the use of a sample frame, it can measure powdered and paste materials.

Designed and manufactured in full compliance with ASTM D5470-2017 standards, tester incorporates over a decade of production experience and user feedback to provide mature and reliable performance. The instrument features servo-controlled precise automatic pressing, automatic thickness measurement, 6-point temperature gradient detection, and computer-controlled fully automatic operation. Built-in thermal protection around the test rod reduces environmental influence, enabling precise measurement of materials under varying pressures. This tester also includes automatic cold-end temperature compensation, eliminating the need for ice-water compensation.

Users can select standard or compact models according to laboratory space constraints without compromising performance. The instrument is widely applied in universities, research institutes, quality inspection laboratories, and industrial production plants.

Application

This tester is suitable for testing:

Thin heat conductors and metals

Solid electrical insulation materials

Thermal greases and thermal silicone pads

Resins, rubber, and engineering plastics

Beryllium oxide ceramics and aluminum oxide ceramics

Aluminum substrates, copper-clad laminates, and composite ceramics

Foam copper, graphite sheets, and other novel thermal interface materials

Typical applications include:

Academic research: Thermal property analysis of materials

Industrial quality control: Verifying thermal performance of production materials

R&D labs: Testing thermal interface materials (TIMs) and adhesives

Production sites: Evaluating aging, reliability, and compression performance of materials

Standards

The instrument complies with:

MIL-I-49456A – Insulating Sheet Materials, Thermally Conductive Resins, Glass-Fiber Reinforced Thermal Materials

GB 5598-2015 – Method for Determining Thermal Conductivity of Beryllium Oxide Ceramics

ASTM D5470-2017 – Test Method for Thermal Transmission Properties of Thin Thermally Conductive Solid Electrical Insulation Materials

GB/T 29313-2012 – Test Methods for Thermal Conductivity of Electrical Insulation Materials

Parameters

| Item | Specification |

|---|---|

| Sample size | Φ30 mm or 20×20 mm (standard); custom sizes available |

| Sample thickness | 0.001–50 mm; typical 0.02–20 mm |

| Hot plate temperature range | Room temperature–100 °C (standard); optional 300 °C or 500 °C |

| Cold plate temperature range | 0–99 °C; precision 0.01 °C (with high-precision low-temperature water bath) |

| Thermal conductivity range | 0.01–50 W/m·K; 0.1–300 W/m·K, software auto-switching |

| Thermal resistance range | 0.05–0.000005 m²·K/W |

| Pressure range | 0–1000 N; servo-controlled; precision 1 N |

| Thickness measurement range | 0–50 mm; resolution 0.1 μm; automatic |

| Sample quantity | 1 piece (thin film, multiple layers) |

| Measurement accuracy | Better than 3% |

| Test modes | Thermal resistance under varying pressures; material thermal conductivity; contact thermal resistance; aging reliability; compression performance; inter-sample contact thermal resistance |

| Automation | Computer-controlled fully automatic measurement and report output |

| Power supply | 220 V / 50 Hz; 500 W |

Features

Measures thermal conductivity, thermal resistance, and interface contact thermal resistance of silicone, ceramic, and insulating materials

Servo-controlled automatic pressing and thickness measurement

6-point temperature gradient detection for high-precision results

Built-in thermal protection reduces environmental influence

Automatic cold-end temperature compensation eliminates ice-water requirements

Can measure both solid sheets and powder/paste materials

Fully computer-controlled with data recording, printing, and reporting

Available in standard and compact models to save laboratory space

Accessories

Main instrument

Analysis software (Chinese & English versions)

Precision low-temperature constant temperature water bath (high-precision, large-capacity)

Calibration reference samples (2 pieces)

Sample accessories set (thermal grease, paste, powder test boxes, stamping molds for sheet samples)

Test Procedures

Prepare the sample according to size and thickness specifications. Powder/paste materials require a sample frame.

Place the sample between the hot and cold plates.

Set desired hot and cold plate temperatures via software.

Apply pressure using the servo-controlled mechanism.

Start the measurement; the system automatically records temperature gradients and thickness.

Wait for completion; software calculates thermal conductivity, thermal resistance, and interface contact thermal resistance.

Save and print results as required.

Maintenance Information

Keep hot and cold plates clean and free from residue.

Regularly calibrate using reference samples.

Inspect thermal protection devices and pressure mechanisms for proper operation.

Maintain stable laboratory conditions to ensure consistent measurements.

Ensure proper operation of water bath for cold plate stability.

FAQ

1. What types of materials can tester test?

This tester can measure thin heat conductors, solid electrical insulation materials, thermal greases, silicone pads, resins, rubber, beryllium oxide ceramics, aluminum oxide ceramics, aluminum substrates, copper-clad laminates, composite ceramics, foam copper, graphite sheets, and other novel thermal interface materials. Powder and paste materials can also be measured with the use of a sample frame.

2. How accurate are the measurements?

The tester achieves better than 3% accuracy for thermal conductivity and thermal resistance measurements. This precision is ensured through 6-point temperature gradient detection, built-in thermal protection, and computer-controlled servo pressing. Even under varying pressures and environmental conditions, the instrument provides reliable, reproducible results.

3. Can this tester measure contact thermal resistance?

Yes. The instrument can measure contact thermal resistance at the interface of solid materials under different pressures. Optimized mathematical models are used to calculate contact resistance accurately. This allows evaluation of materials’ interface performance in practical applications.

4. What sample sizes and thicknesses are supported?

Standard sample sizes are Φ30 mm or 20×20 mm, and thickness ranges from 0.001–50 mm, with typical thickness of 0.02–20 mm. Custom sample sizes are available upon request.

Leave Message Get Price