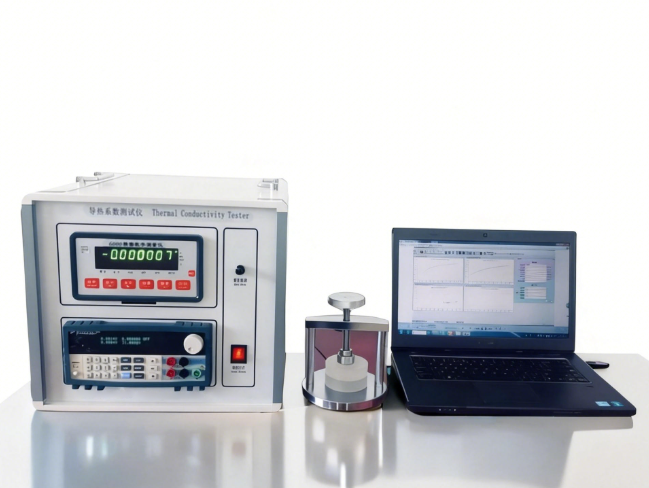

Automatic Dual-Plate Thermal Conductivity Tester

Fully Automatic Dual-Plate Thermal Conductivity Tester (Guarded Hot Plate Method) is a precision instrument designed for thermal conductivity measurement of homogeneous and heterogeneous board materials. Based on unidirectional steady-state heat transfer principles, the instrument measures heat flux through the sample, the temperature difference between the upper and lower surfaces, and the sample thickness to calculate thermal conductivity.

The tester is fully computer-controlled and automates all testing and data processing, ensuring high accuracy and reproducibility. It is suitable for both solid boards and loose, granular, or soft materials when used with appropriate sample fixtures.

Application

This tester is suitable for testing the thermal conductivity of:

Plastics, rubber, glass, and fiber boards

Polystyrene foam (EPS), extruded polystyrene foam (XPS), polyurethane rigid foam

Foamed concrete, hollow glass, wood boards

Various insulation materials

Granular, loose, or soft materials (with optional fixtures)

Typical applications include:

Quality inspection of insulation and construction materials

R&D in thermal performance of polymer and foam materials

Academic research in thermal properties of solid and granular samples

Industrial production control for plastics, foams, and composite boards

Standards

The instrument complies with the following international and national standards:

GB/T 10294-2008 – Determination of Steady-State Thermal Resistance and Related Properties of Insulating Materials

GB/T 3399-1982 – Test Method of Thermal Conductivity for Plastics by Guarded Hot Plate Method

GB/T 10801.1-2002 – Measurement of Thermal Conductivity for Polyurethane Rigid Foam in Thermal Insulation

GB/T 10801.2-2002 – Measurement of Thermal Conductivity for Extruded Polystyrene Foam (XPS)

GB/T 3139-2005 – Test Method of Thermal Conductivity for Fiber Reinforced Plastics

GB/T 17794-2008 – Flexible Foam Rubber and Plastic Thermal Insulation Products

Parameters

| Item | Specification |

|---|---|

| Thermal conductivity range | 0.001–3.000 W/m·K |

| Measurement accuracy | ±2% |

| Repeatability | ±1% |

| Hot plate temperature range | Room temperature–150 °C (standard); optional up to 300 °C |

| Hot plate resolution | 0.01 °C |

| Cold plate temperature range | 0–60 °C (standard); optional -5–60 °C |

| Cold plate resolution | 0.01 °C |

| Sample thickness | 0–100 mm; resolution 0.001 mm; automatic measurement |

| Applied pressure | 0–500 N; resolution 0.1 N |

| Sample size | 300×300×(5–50) mm (standard); custom sizes available |

| Automation | Fully computer-controlled testing and data processing |

| Test duration | 60 minutes |

| Power supply | 220 V / 50 Hz; 500 W |

Features

Online temperature calibration: Unique technology allows fast, accurate calibration, improving accuracy by over 3 times.

Reduced testing time: Full testing completed in approximately 60 minutes.

Wide measurement range: Thermal conductivity 0.001–3.000 W/m·K.

Automatic thickness measurement: Computer-controlled, minimizing human error.

Automatic pressure control: Accurate, reproducible testing under varying pressures.

Versatile measurement: Supports solid boards and, with optional accessories, granular and loose materials.

Fully automated system: From measurement to data analysis and report output.

Accessories

Main instrument

Analysis software (Chinese & English versions)

HX-1005 precision low-temperature constant temperature water bath (0.01 °C accuracy)

Desktop computer (user-selected)

Calibration reference sample

Test Procedures

Prepare the sample according to size and thickness specifications. For loose or granular materials, use the optional sample fixture.

Place the sample between the hot and cold plates.

Set hot and cold plate temperatures via software.

Apply desired pressure using the computer-controlled automatic system.

Start the measurement; the system records temperature gradients and sample thickness automatically.

Wait for the completion of testing (approx. 60 minutes).

Software calculates thermal conductivity and generates data reports.

Maintenance Information

Keep hot and cold plates clean and free from residues.

Periodically calibrate using reference samples.

Inspect the pressure system and thickness sensors to ensure proper operation.

Maintain a stable laboratory environment to reduce measurement errors.

Ensure proper operation of the water bath for consistent cold plate temperature.

FAQ

1. What materials can this tester measure?

The tester can measure thermal conductivity of plastics, rubber, glass, fiber boards, EPS, XPS, polyurethane rigid foam, foamed concrete, hollow glass, wood boards, and other insulation materials. With optional fixtures, granular and soft materials can also be measured.

2. How accurate are the measurements?

The instrument provides ±2% accuracy for thermal conductivity and ±1% repeatability. Accuracy is ensured through fully automated computer-controlled testing, online temperature calibration, and precise pressure and thickness control. The system minimizes environmental influences and human errors.

3. Can this tester test materials under different pressures?

Yes. The tester has an automatic pressure system controlled via software, allowing measurement of thermal conductivity under varying pressures. This improves reproducibility and provides more reliable data compared to manual pressing.

4. What is the typical test duration?

A full thermal conductivity measurement takes approximately 60 minutes. This includes sample placement, automatic thickness and pressure control, and calculation of results. Software provides automatic data processing and report generation at the end of the test.

Leave Message Get Price