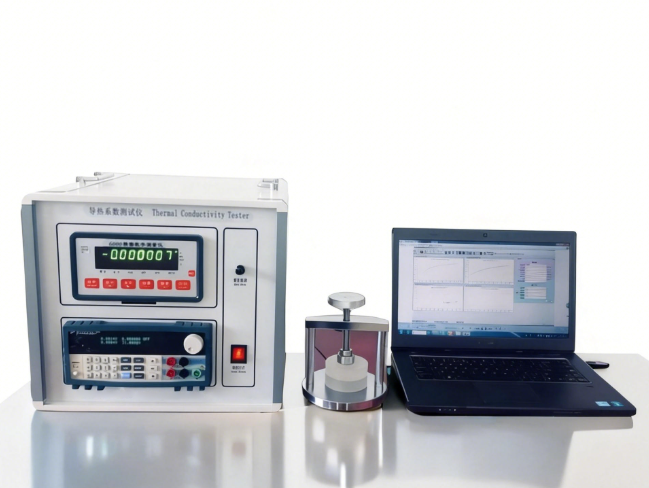

High-Precision Material Thermal Conductivity Tester

High-Precision Material Thermal Conductivity Tester (Guarded Hot Plate Heat Flow Meter Method) is a fully automated thermal property testing system designed for accurate measurement of thermal conductivity and thermal resistance using the internationally recognized heat flow meter principle. The instrument applies a stable controlled temperature to one side of the specimen, allowing heat to transfer through the material to a cooled surface, while the transmitted heat flux is precisely measured to calculate thermal conductivity and thermal resistance. Equipped with imported sensors and computer-based control and data processing, the system delivers high accuracy, strong reliability, and excellent repeatability, especially for low thermal conductivity materials.

Application

The High-Precision Material Thermal Conductivity Tester is suitable for steady-state thermal performance evaluation of materials with low to medium thermal conductivity, including:

Thermal insulation materials

Plastics and polymer-based materials

Rubber and elastomer materials

Aerogel panels and advanced insulation boards

Vacuum glass and building energy-saving materials

Solid materials and powder materials (with appropriate sample configuration)

The instrument is widely used in universities, research institutes, quality inspection laboratories, and industrial material testing facilities for thermal conductivity and thermal resistance analysis.

Standards

The instrument is designed and operated in accordance with the following international and national standards:

GB/T 10295-2008 Thermal insulation — Determination of steady-state thermal resistance and related properties — Heat flow meter method

ASTM E1530 Standard Test Method for Evaluating the Resistance to Thermal Transmission of Materials by the Guarded Heat Flow Meter Technique

ASTM C518-04 Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus

Parameters

| Item | Specification |

|---|---|

| Thermal conductivity range (low range) | 0.0001 – 1 W/m·K (resolution up to 0.1 mW/m·K) |

| Thermal conductivity range (extended) | 0.001 – 300 W/m·K |

| Measurement accuracy | ±1% |

| Sample size | 50 × 50 to 300 × 300 mm |

| Maximum sample thickness | ≤ 50 mm |

| Optional sample sizes | 600 × 600 mm, 800 × 600 mm (customized) |

| Applicable sample form | Solid materials, powder materials |

| Test duration | 15 – 20 min |

| Hot plate temperature range | Room temperature to 99.9 °C (standard) |

| Optional hot plate range | Room temperature to 499.9 °C or higher (by agreement) |

| Hot plate control accuracy | 0.1 °C |

| Cold plate temperature range | 0 – 99.9 °C (standard); –10 – 99.9 °C optional |

| Cold plate temperature control | Water-cooled, precision constant-temperature bath |

| Cold plate control accuracy | 0.1 °C |

| Pressure range | 0 – 1000 N |

| Pressure resolution | 0.1 N |

| Thickness measurement range | 0 – 50 mm |

| Thickness resolution | 0.1 μm |

| Heat flow sensor | Imported original heat flow meter |

| Test operation | Fully automatic computer-controlled testing and data storage |

| Power supply | AC 220 V / 50 Hz |

Features

Guarded hot plate heat flow meter method for steady-state thermal measurement

High sensitivity for low thermal conductivity materials, resolution down to 0.1 mW/m·K

Imported heat flow sensors ensuring stable and reliable performance

Computer-controlled temperature regulation and pressure loading

Automatic thickness measurement with high resolution

Excellent accuracy, repeatability, and long-term measurement stability

Automatic data acquisition, analysis, storage, and report generation

Suitable for both solid and powder materials

Accessories

Main testing unit

Thermal analysis software (Chinese and English versions)

HX-1005 precision low-temperature constant-temperature water bath (0.01 °C accuracy)

Computer (user-selectable)

Calibration reference sample

Test Procedures

Prepare the specimen according to size and thickness requirements.

Place the specimen between the hot plate and cold plate.

Set the target hot-side and cold-side temperatures in the software.

Apply pressure automatically to ensure stable contact.

Allow the system to reach steady-state heat transfer conditions.

Measure the heat flux and temperature gradient across the specimen.

Calculate thermal conductivity and thermal resistance automatically.

Save and print test data and reports.

Maintenance Information

Keep hot and cold plate surfaces clean and undamaged

Ensure proper operation of the constant-temperature water bath

Periodically check sensor performance and calibration status

Maintain stable laboratory environmental conditions during testing

Store reference samples and accessories properly when not in use

FAQ

1. What testing principle does the Thermal Conductivity Tester use?

The tester adopts the guarded hot plate heat flow meter method, a steady-state testing technique widely used for measuring thermal conductivity and thermal resistance. During the test, a stable and controlled temperature is applied to one side of the specimen, and heat flows through the material toward a cooled surface. By accurately measuring the transmitted heat flux and temperature difference, the system calculates thermal conductivity and thermal resistance. This method is particularly suitable for insulation and low thermal conductivity materials.

2. What types of materials are best suited for this instrument?

The instrument is especially suitable for materials with low thermal conductivity, such as insulation materials, plastics, rubber, aerogel panels, and vacuum glass. It can test both solid materials and powder materials with appropriate sample configurations. Thanks to its high sensitivity and stable steady-state measurement principle, the tester provides reliable results even for materials with very low heat transfer rates, where transient methods may be less effective.

3. How accurate is the tester in low thermal conductivity measurements?

The system offers a measurement accuracy of ±1% and can resolve thermal conductivity values down to 0.1 mW/m·K in the low-conductivity range. This high sensitivity is achieved through the use of imported heat flow sensors, precise temperature control on both hot and cold plates, and automatic pressure and thickness measurement. These features ensure excellent repeatability and consistency in low thermal conductivity testing.

4. Is the testing process fully automated?

Yes. The entire testing process, including temperature control, pressure application, heat flux measurement, data acquisition, and report generation, is controlled by computer software. Test data can be stored, printed, and reviewed automatically, improving testing efficiency and reducing operator influence.

Leave Message Get Price