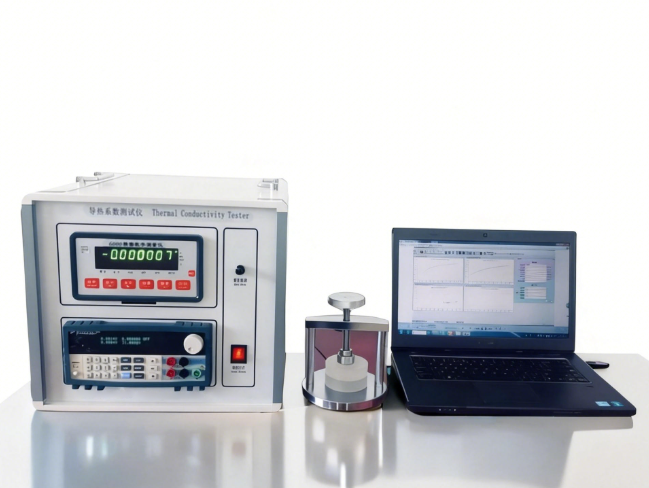

Guarded Heat Flow Meter

The Guarded Heat Flow Meter is a precision instrument designed to measure the thermal resistance and thermal conductivity of solids, including metals, polymers, composites, and pastes, over a temperature range of -20°C to 310°C. By replacing traditional pneumatic motion with advanced motorized control, the system achieves automatic adjustment of sample thickness, applied pressure, and force. This instrument provides highly accurate steady-state measurements, enabling precise evaluation of materials’ thermal performance and aiding in quality control, research, and energy efficiency assessment.

Application

Measurement of thermal conductivity and thermal resistance of metals, polymers, composites, and pastes.

Characterization of thermal performance for materials in aerospace, electronics, automotive, and industrial applications.

Determination of steady-state heat transfer for heterogeneous or non-uniform materials.

Applicable for quality control, material research, R&D, and certification testing.

Standards

ASTM E1530: Standard Test Method for Evaluating Thermal Resistance of Materials Using a Guarded Heat Flow Meter.

ASTM E1560-19: Standard Test Method for Thermal Conductivity Measurements with Guarded Heat Flow Meter.

Parameters

| Item | Specification / Description |

|---|---|

| Applicable Materials | Metals, Polymers, Composites, Pastes |

| Sensor Type | Thermocouples (x6) |

| Measurement Direction | Through-thickness |

| Thermal Conductivity Range | 0.1 – 100 W/m·K * |

| Sample Diameter | 50 – 50.8 mm |

| Sample Thickness | Up to 25 mm (0.1 mm optional for soft materials) |

| Test Time | 40 – 60 minutes |

| Accuracy | 3% (k) |

| Repeatability | 1 – 2% (k) |

| Temperature Range | -20 to 310 °C ** |

| Pressure | Automatic, up to 379 kPa (55 psi) |

| Notes |

*

Materials with conductivity >60 W/m·K must have thickness ≥12.5 mm ** Each system includes a refrigeration circulator |

Replaceable Heat Flow Module: Tool-free replacement of the calibrated heat flux sensor module.

Comprehensive Temperature Monitoring: Multiple thermocouples ensure sample temperature gradient is at steady-state during testing.

Precision Thickness Measurement: Proprietary universal design allows automated thickness measurement for rigid materials or user-defined thickness/pressure for compressible samples. Optical encoders provide ±0.025 mm accuracy.

Temperature Control: Heat exchanger with thermocouples enables precise heating and cooling; lateral heat loss minimized using guarded furnace; software allows precise temperature programming.

Clamping Control: Automatic clamping for rigid samples; software-controlled height/pressure (up to 379 kPa / 55 psi) for soft materials, with automatic stop once desired parameters are reached.

Steady-State Measurement: Ensures accurate thermal resistance and conductivity by maintaining stable temperature gradients through the sample.

Accessories

Contact paste for top and bottom surfaces.

Optional software module for custom temperature programming.

Standard calibration samples with known thermal resistance and conductivity.

Refrigeration circulator for low-temperature testing.

Test Procedures

Sample Preparation: Ensure sample diameter is 50–50.8 mm and top/bottom surfaces are flat and parallel. Apply a thin layer of contact paste (~1 min).

Load Sample: Place the sample into the test stack. For rigid materials, the upper stack applies default system pressure. For soft materials, define the desired pressure or thickness. Parameters can be controlled within the test plan (~1 min).

Measurement: Set single or unlimited temperature steps (up to 300°C). Internal red backlight indicates test in progress (~40–60 min).

Export Results: Temperatures of upper and lower test plates are monitored to ensure stability. Thermal resistance and calculated conductivity are displayed in tabular form and can be exported to Excel. Internal blue backlight indicates test completion and safe handling (~1 min).

Maintenance Information

Regularly clean thermocouple and heat flux sensor surfaces to avoid debris interference.

Periodically check calibration using reference samples with known thermal properties.

Inspect mechanical components of motorized stack and encoders to maintain accuracy.

Store in a dry, temperature-stable environment when not in use.

FAQ

What types of materials can be tested with the Guarded Heat Flow Meter?

The Guarded Heat Flow Meter can test metals, polymers, composites, and pastes. It measures thermal resistance and thermal conductivity over a wide temperature range (-20°C to 310°C), making it suitable for a variety of industrial, R&D, and quality control applications.

How is sample thickness controlled during measurement?

For rigid materials, thickness is automatically determined using optical encoders. For compressible materials, the user can define thickness or applied pressure, which is then automatically maintained by the test stack. This ensures optimal contact and precise measurement of thermal properties.

How are thermal resistance and conductivity calculated?

The sample is placed between a heated upper plate and cooled lower plate with embedded thermocouples. Once steady-state temperature gradient is achieved, Fourier’s law is applied using measured temperatures and sample thickness. Calibrated constants F and Rint allow accurate calculation of RS (m²·K/W) and conductivity λ (W/m·K), ensuring reliable results for heterogeneous materials.

Leave Message Get Price