Burning Manikin System

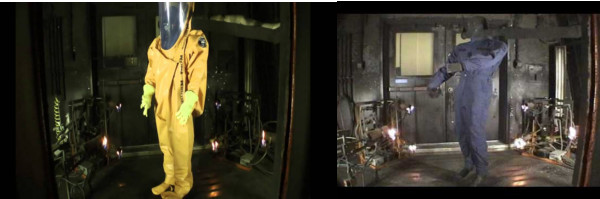

The burning manikin system is used to test the overall thermal protection performance of protective clothing.Complete combustion manikin system, which consists of combustion chamber, burning manikin and gas control system and other components.

Standard:

EN ISO 11612, EN ISO 11611, ISO 13506, EN469:2005.

Principle:

The burning manikin system is composed of:

1. computer combustion dummy;

2. thermal sensor group;

3. flame generator;

4. computer control module;

5. data acquisition and processing module;

6. burn analysis module.

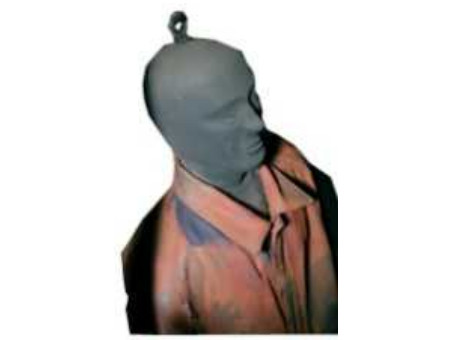

1. The burning manikin model uses 1: 1 adult male model, the material is FRP with stable, flame inert and high strength performance, and 2 ~ 3mm thickness, 1.72m2 surface area. There are a certain number of sensors in the manikin model’s head, trunk, legs and arm surface evenly. The manikin model’s outer surface paints black and flame retardant coating. The processed sensor data export lines on the head facilitate the instrument to capture the data signal.

![]()

2. The sensor group includes thermal sensor and pressure sensor. The heat sensor consists of more than 120 heat flow sensors, which are evenly distributed on the manikin's surface, and each sensor represents the physical condition of the skin of a certain surface area. Numbered every sensor, and if the temperature value calculated by the sensor passes burns are estimated to meet the two or three burning degrees, then mark them into a simulated digital human body model with different colors. Since the flame temperature change is a dynamic process, the test sensor temperature range is higher and the response time is shorter to achieve the flame dynamic process of the test. Pressure sensor is mainly used to measure the gas container and gas pipeline gas pressure value, to ensure safe and controllable experimental.

3. The flame generation device consists of 6 groups of 12 propane flame generators around manikin. Each group of flame generators consists of a high pressure liquefied gas tank, a buffer gas tank, a pressure pipe and a gas pressure sensor, a adjustable flame nozzle, and a pilot flame device. Flame action time is controlled by the computer control simulation module, the flame intensity during this period maintains uniform and stable.

4. The computer control module is composed of pre-programmed software. The main function is to automatically check the status of each group of sensors associated with the experiment before the start of the experiment. Send the command when no problem. In the course of the experiment, the computer control program controls the time and intensity of the flame generator, automatically guide the data processing module and record the data changes of the various sensors. In the end of experimental stage, downloaded and saved the recorded data into the form of the document, and guide the exhaust ventilation system on the combustion test chamber for ventilation.

5. Data acquisition and processing simulation. With the help of computer control module, preprocess the signal of the amplification, conversion and storage data for control temperature sensor and heat flow sensor acquisition. the heat flow signal transfer into the corresponding temperature value through the model, and then the results are temporarily stored for the burn estimator module use.

6. The burn estimation module is intended to estimate the extent of burns caused by the flame. The information of the manikin surface temperature value obtained by the sensor is input to the burn estimation model. After the burn estimation operation, the burn integral value and the burn program value are obtained. Combined with the plot of the digital human body model to get the second and third degree burns on the scattergram manikin's surface.

The Burning Manikin System fully meets the relevant technical indicators of ISO13506, ASTMF1930 and other combustion dummy system evaluation. The size of the dummy body adopts the standard body shape of a Chinese adult male, and 135 heat flow sensors are installed on the whole body, covering various parts such as the torso, head, hands and feet. It can be used for the evaluation of thermal protective clothing, and can also meet the needs of the evaluation of a complete set of thermal protective equipment such as helmets, gloves, and fireproof boots. The sliding system can simulate various postures and activities of the human body.

Leave Message Get Price