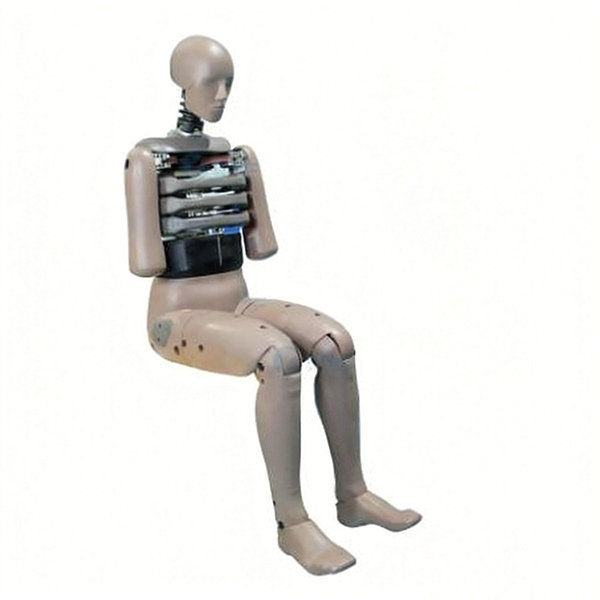

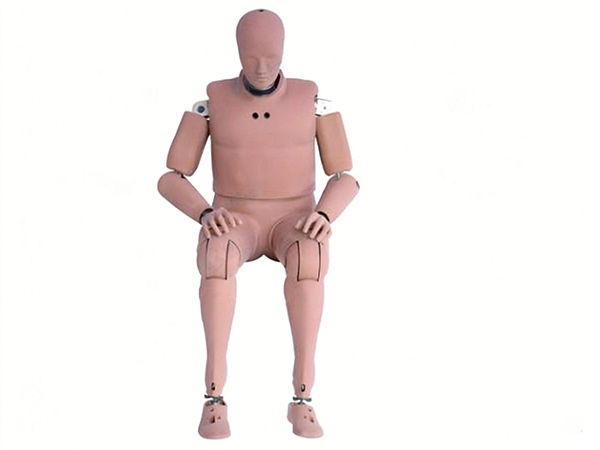

50th Percentile Male Side Impact Dummy

The 50th Percentile Male Side Impact Dummy represents an average adult male in terms of body size and mass. Developed based on AMVO 50th percentile male data, and optimized using multiple anthropometric databases covering different populations, this dummy provides high-fidelity biomechanical responses for side impact testing. Its design complies with ISO/TR 9790 evaluation procedures, and has been validated through 33 tests to assess its biofidelity, providing reliable data for vehicle side safety design and occupant injury protection research.

Application

The 50th Percentile Male Side Impact Dummy is primarily used for:

(1) Vehicle side impact occupant protection testing;

(2) Evaluation of B-pillar, door trim, and sill beam crashworthiness;

(3) Verification of side airbags and curtain airbag restraint systems;

(4) Safety development and regulatory certification for new or updated vehicle models;

(5) Occupant injury assessment and crash safety research;

(6) High-repetition crash data collection for research institutions and testing labs;

(7) International and regional NCAP (Euro NCAP, C-NCAP, U.S. NCAP, etc.) side impact tests.

Standards

(1) GB/T 11551 – Protection of occupants in frontal and side collisions

(2) GB 14166 – Motor vehicle seat belts and restraint systems

(3) FMVSS 214 – Side impact protection

(4) UNECE R95 – Lateral collision protection

(5) UNECE R135 – Pole side impact

(6) SAE J1727 – Side impact dummy performance specification

(7) ISO 15830 – Road vehicles – Side impact dummy – Calibration

(8) ISO/TR 9790 – Road vehicles – Side impact dummy – Evaluation method

(9) Euro NCAP – Side impact test protocol

Parameters

Dimensional Data

| No. | Item | Dimension (mm) |

|---|---|---|

| L1 | Sitting height | 869 ±30 |

| L2 | Hip joint pivot height | 79 ±15 |

| L3 | Hip pivot to back distance | 175 ±28 |

| L4 | Thigh gap | 176 ±29 |

| L5 | Foot to knee height | 588 ±30 |

| L6 | Knee to back distance | 670 ±30 |

| L7 | Rear head to back distance | 147 ±22 |

| L8 | Upper rib thorax depth | 208 ±30 |

| L9 | Lower rib/abdomen thorax depth | 228 ±30 |

| L10 | Arm length | 330 ±30 |

| L11 | Arm breadth | 468 ±30 |

| L12 | Waist breadth | 324 ±30 |

Mass Distribution

| Component | Mass (kg) |

|---|---|

| Head | 4.29 ±0.05 |

| Neck | 2.86 ±0.02 |

| Shoulders/Thorax/Abdomen | 20.56 ±0.35 |

| Two half-arms | 3.52 ±0.08 |

| Lumbar spine and pelvis | 19.3 ±0.2 |

| Two thighs | 11.72 ±0.08 |

| Two lower legs (including ankles/feet) | 10.12 ±0.14 |

| Clothing | 1.54 ±0.1 |

| Total dressed dummy weight (with half-arms installed) | 73.91 ±1.02 |

Sensor Configuration

| Location | Sensor | Measurement | Channels |

|---|---|---|---|

| Head | Accelerometer | Acceleration | 1×3 |

| Head | Gyroscope | Angular velocity | 3×1 |

| Head | Tilt sensor | Tilt angle | 1×2 |

| Neck | Upper load cell | Force | 1×6 |

| Neck | Lower load cell | Force | 1×6 |

| Neck T1 | Accelerometer | Acceleration | 1×3 |

| Shoulder | Shoulder joint load cell | Force | 1×3 |

| Spine T4 | Accelerometer | Acceleration | 1×3 |

| Spine T12 | Accelerometer | Acceleration | 1×3 |

| Spine | Gyroscope | Angular velocity | 2×1 |

| Spine | Tilt sensor | Tilt angle | 1×2 |

| Spine | Temperature sensor | Temperature | 1×1 |

| Shoulder/Rib | Temperature sensor | Acceleration | 1×3 |

| 2D IR-TRACC | Displacement sensor | Displacement | 1×1 |

| Thorax/Rib | Accelerometer | Acceleration | 3×3 |

| 2D IR-TRACC | Displacement sensor | Displacement | 3×1 |

| Abdomen/Rib | Accelerometer | Acceleration | 2×3 |

| 2D IR-TRACC | Displacement sensor | Displacement | 2×1 |

| Pelvis | Accelerometer | Acceleration | 1×3 |

| Pelvis | Gyroscope | Angular velocity | 3×1 |

| Pelvis | Tilt sensor | Tilt angle | 1×2 |

| Lumbar spine | Load cell | Force | 1×6 |

| Pubis | Load cell | Force | 1×1 |

| Sacrum | Load cell | Force | 1×6 |

| Femur muscle | Load cell | Force | 2×3 |

| Legs | Thigh load cell | Force | 1×6 |

| Tibia | Upper tibia load cell | Force | 1×6 |

| Tibia | Upper tibia load cell | Force | 1×6 |

| Knee | Load cell | Force | 2×1 |

| Knee | Angle sensor | Angle | – |

Features

(1) Represents a 50th percentile adult male, average body type;

(2) Skeletal and joint design ensures high biofidelity, with accurate thorax and abdomen force responses;

(3) Supports multi-channel measurement of acceleration, force, displacement, angular velocity, tilt, and temperature;

(4) Complete shoulder-rib, thorax-rib, abdomen-rib, and pelvis measurement systems for high-precision injury assessment;

(5) Compliant with international side impact regulations and ISO/TR 9790 evaluation procedures;

(6) Stable structure suitable for repeated side impact tests at various speeds.

Accessories

(1) Accelerometer and gyroscope modules

(2) Multi-channel load cells and displacement sensors

(3) IR-TRACC displacement sensors

(4) Temperature sensors

(5) Replaceable limb and torso modules

(6) Calibration tools and data acquisition interfaces

(7) Dedicated transport and mounting frame

Test Procedures

(1) Fully calibrate the dummy, including sensor zeroing and sensitivity;

(2) Install the dummy according to specified dimensions and posture, avoiding joint lock-up;

(3) Adjust seat, restraint systems, and sled parameters according to different test standards;

(4) Ensure secure data acquisition connections, avoiding cable tension or interference;

(5) Post-test inspection of ribs, sensors, and structural components to prevent cumulative damage.

Maintenance Information

(1) Inspect ribs, thorax, and pelvis for cracks or wear;

(2) Check all sensor connections and data acquisition equipment;

(3) Lubricate joints and secure detachable modules;

(4) Keep surfaces clean and protected from moisture or corrosive agents;

(5) Store in controlled environment (avoid extreme temperature, humidity, UV);

(6) Record maintenance and usage history after each test.

FAQ

(1) What is this product?

A high-fidelity 50th percentile male side impact dummy for vehicle safety testing.

(2) What is this product used for?

Side impact safety assessment, B-pillar and door evaluation, airbag and restraint system verification, and occupant injury research.

(3) How does it work?

It reproduces human skeletal, joint, and soft tissue biomechanics. Multi-channel sensors record acceleration, force, displacement, angle, and temperature during side collisions.

(4) Why is it important?

It provides reliable data to assess and improve vehicle side protection systems, ensuring compliance with regulations and occupant safety.

(5) What industries is it suitable for?

Automotive OEMs, testing labs, research institutes, and universities conducting vehicle safety studies.

Leave Message Get Price