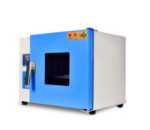

G505-filter Medium Tester

G505 Filter medium tester is used to simulate the use procedure of the filter bag in the bag filter, and the filter material is aged according to the standard procedure (usually it takes many days), the"characteristic filtration index" (including pressure drop curve, residual pressure drop, filtration/cleaning cycle, residual dust layer quality, and dust quality of penetrating filter material samples) of the specific concentration of aerosol penetrating before and after the filter material can be tested after the performance of the filter material tends to be stable. The results of the indicator can be used to evaluate the filtration efficiency of the filter material during actual use.

G505 Filter medium tester

Standards compliant

G505 Filter medium tester 5 Several Major Features

1. Imported parts

The pressure sensors, concentration sensors, differential pressure sensors,temperature sensors and humidity sensors, mass flow controllers, vacuum pumps, particle size analyzers and other important components of the tester are all using imported accessories, with high precision, stable and reliable performance, good repeatability, and accurate test data.

The pressure sensors, concentration sensors, differential pressure sensors,temperature sensors and humidity sensors, mass flow controllers, vacuum pumps, particle size analyzers and other important components of the tester are all using imported accessories, with high precision, stable and reliable performance, good repeatability, and accurate test data.

2. High degree of automation

The pressure sensors, concentration sensors, differential pressure sensors,temperature sensors and humidity sensors, mass flow controllers, vacuum pumps, particle size analyzers and other important components of the tester are all using imported accessories, with high precision, stable and reliable performance, good repeatability, and accurate test data.

The pressure sensors, concentration sensors, differential pressure sensors,temperature sensors and humidity sensors, mass flow controllers, vacuum pumps, particle size analyzers and other important components of the tester are all using imported accessories, with high precision, stable and reliable performance, good repeatability, and accurate test data.

3. Automatic feeding device

The pressure sensors, concentration sensors, differential pressure sensors,temperature sensors and humidity sensors, mass flow controllers, vacuum pumps, particle size analyzers and other important components of the tester are all using imported accessories, with high precision, stable and reliable performance, good repeatability, and accurate test data.

The pressure sensors, concentration sensors, differential pressure sensors,temperature sensors and humidity sensors, mass flow controllers, vacuum pumps, particle size analyzers and other important components of the tester are all using imported accessories, with high precision, stable and reliable performance, good repeatability, and accurate test data.

4. Automatic clamping device

The pressure sensors, concentration sensors, differential pressure sensors,temperature sensors and humidity sensors, mass flow controllers, vacuum pumps, particle size analyzers and other important components of the tester are all using imported accessories, with high precision, stable and reliable performance, good repeatability, and accurate test data.

The pressure sensors, concentration sensors, differential pressure sensors,temperature sensors and humidity sensors, mass flow controllers, vacuum pumps, particle size analyzers and other important components of the tester are all using imported accessories, with high precision, stable and reliable performance, good repeatability, and accurate test data.

5. Transparent observable window

The pressure sensors, concentration sensors, differential pressure sensors,temperature sensors and humidity sensors, mass flow controllers, vacuum pumps, particle size analyzers and other important components of the tester are all using imported accessories, with high precision, stable and reliable performance, good repeatability, and accurate test data.

The pressure sensors, concentration sensors, differential pressure sensors,temperature sensors and humidity sensors, mass flow controllers, vacuum pumps, particle size analyzers and other important components of the tester are all using imported accessories, with high precision, stable and reliable performance, good repeatability, and accurate test data.-

Field Application

G505 Filter medium tester, t is applicable for quality control of filter material industrial production enterprises and products performance verification of filter material research&development enterprises.

It is applicable to the performance verification of new products, quality control of the production department, and the of material properties for the third-party testing organization, the product performance verification laboratory, and the quality and technical supervisiondepartment, etc.

-

Configuration parameter

-

Optional Accessories

-

Configuration parameter

Configuration parameter

| Technical Parameters | |

| Test mode: automatic | Sample diameter:150mm |

| Dust emission: 42mg-420 g/h(reference dust, SAE, Fine A2 Dust) | Filter material surface wind speed: 0.5-5 m/min<±2% |

| Flow rate:5-10 m³/h±1% | Sample clamping method: pneumatic clamping |

| Gas storage tank:4.5 L |

Distance between nozzle and filter material sample:840mm±70mm |

| Dust concentration: 0.8-100 g/m3, accuracy <±7% | |

| Dust generator weighing unit: 50kg loading unit, accuracy 1g | Flow rate range:0-6 m3/h |

|

Dirty gas pipeline temperature: temperature range 0-100℃, accuracy ± 0.3℃ |

Filter material pressure drop sensor:0-2500Pa±0.5% |

| Reaction time:2.5s | |

|

Dirty gas pipeline humidity: temperature range 0-100RH, accuracy ± 4%, |

Repeated accuracy:0.1% |

| Long-term stability:0.5%FSD/year | |

| Sensor pressure:0-1100mbar±0.5% |

Maximum temperature difference range: 1% of FS 0℃ to 50℃ |

| Flow rate::0-12 m3/h±1% | |

| Concentration sensor(:0~10)g/m3 | Compressed air tank volume:≥4 .5L |

| Test content: it tests the dust concentration and dispersion. | Tank pressure: 0-0.7 MPa ± 3%; (it can be adjusted freely) |

| Luminance meter: the integration period is less than 10 seconds, and the laser energy is 1mW. Wavelength 650nm±10nm |

Valve opening time: 50ms-250 ms (it can be adjusted freely) |

| Weight:700kg | |

|

Test dust:0.25μm-32μm |

Power supply:380V 50Hz |

| Cyclone combination:PM1/PM2.5/PM10 |

Appearance size:2400x1200x3500 |

| Test sample diameter:140mm | |

Leave Message Get Price