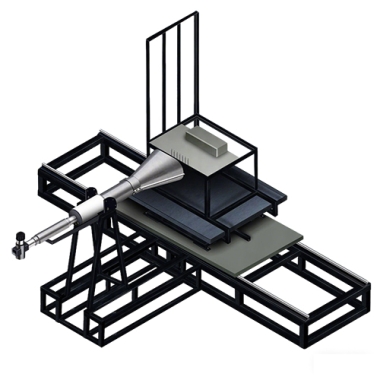

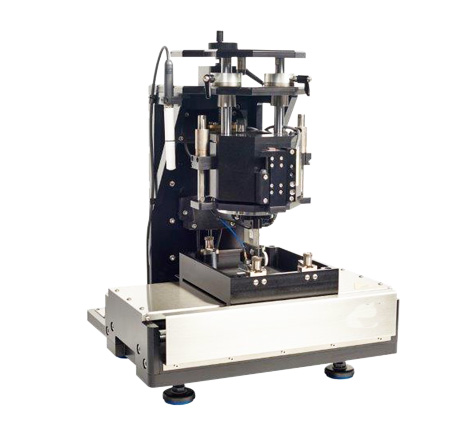

Stick-Slip – Tribological Test Stand (G-H3P)

The Stick-Slip Tribological Test Stand is designed to predict stick-slip noise (“squeak” or “creak”) in automotive interior and functional components. It measures critical parameters including static friction, dynamic friction, maximum frictional acceleration, vibration frequency, and friction coefficient. The system can simulate environmental conditions such as water, grease, dust, and temperature changes, providing reliable data for material selection, design optimization, and quality control in automotive interiors and functional parts.

Application

(1) Automotive interior materials: evaluation of friction performance on seat leather, door panel soft materials, instrument panels, and center console materials.

(2) Automotive functional components: friction noise prediction for armrests, steering wheels, door handles, cup holders, etc.

(3) Material compatibility studies: analysis of stick-slip behavior in different material combinations, predicting potential squeak noise.

(4) Friction performance research: measurement of static friction, dynamic friction, frictional acceleration, friction coefficient, and pulse frequency.

(5) Environmental factor evaluation: assessment of water, oil, dust, and temperature impact on stick-slip and friction properties.

(6) Surface optimization: supports surface treatment, coating improvement, and material formulation optimization.

(7) Quality control and R&D: provides critical parameter references for product development and manufacturing.

Standards

(1) VDA 230-206 – German automotive friction noise standard.

(2) BMW PR315, BMW TL 9169300.

(3) VW / Audi / Porsche TL 52064, PV3981.

(4) Ford L400.

(5) TPJLR-00-230 – Jaguar Land Rover friction noise and friction performance standard.

Note: Standards cover automotive friction noise testing, friction force measurement, and environmental simulation requirements.

Parameters

| Parameter | Range / Specification | Description |

|---|---|---|

| Relative Speed (Linear Motor) | 1–150 mm/s | Simulates real friction speed |

| Stroke | 10–100 mm | Adjustable for different materials |

| Load Range | 2–80 N | Simulates different contact pressures |

| Temperature Range | -30℃ to 80℃ | Simulates environmental conditions |

| Static/Dynamic Friction Force | 0–35 N | Accurate measurement of friction forces |

| Maximum Acceleration | 0–25 g | Records stick-slip transition |

| Measurement Angle | 0–80° | Adapts to different material contact angles |

| Friction Frequency | 0–150 Hz | Simulates vibration frequency and friction state |

| Feed Mode | Force Control / Displacement Control | Programmable testing modes |

| Machine Dimensions | 250 × 250 mm | Compact lab tabletop design |

| Control System | PLC / PC | Real-time data acquisition and report generation |

Features

(1) High-precision measurement: combination of linear motor and force/acceleration sensors ensures accurate friction, acceleration, and pulse frequency measurement.

(2) Environmental simulation: testing under varying temperature, water, oil, and dust conditions.

(3) Quantifiable stick-slip noise: risk assessment (RPN) predicts potential squeak noise.

(4) Flexible testing: supports force control and displacement control modes to simulate diverse real-world scenarios.

(5) Data visualization: real-time curves and automatic report generation for R&D analysis.

(6) Compact and reliable: linear motor-driven structure, small footprint, low maintenance.

(7) Safety: optional protective enclosure prevents operator injury during testing.

Accessories

| Accessory | Specification | Function |

|---|---|---|

| Test Material Fixture | Adjustable | Secures sample, ensures stable friction testing |

| Friction Test Head | Metal or Rubber | Simulates fingertip, shoe sole, or component surface |

| Force Sensor | 0–80 N | Measures static and dynamic friction forces |

| Acceleration Sensor | 0–25 g | Records stick-slip acceleration variations |

| Temperature Control Plate | -30℃ to 80℃ | Simulates different environmental temperatures |

| Data Acquisition System | PC / PLC | Real-time collection of friction, acceleration, and pulse data |

| Software | RPN Calculation and Visualization | Risk assessment, pulse frequency analysis, reporting |

Test Procedures

(1) Prepare sample material and fix it on the test fixture, ensuring flat surface.

(2) Install and calibrate friction test head, force sensor, and acceleration sensor.

(3) Set test parameters: load, stroke, speed, temperature, and cycles.

(4) Start the test program, monitor real-time friction, acceleration, and pulse frequency.

(5) After testing, save data, generate curves, and perform RPN risk assessment report.

(6) Ensure safety: avoid operator contact with moving parts, use protective enclosure if necessary.

Maintenance Information

(1) Clean force, acceleration, and test head surfaces regularly.

(2) Calibrate sensors periodically to maintain accuracy.

(3) Inspect linear motor and fixture for mechanical wear.

(4) Verify environmental simulation equipment (temperature, water, dust) functions properly.

(5) Update software and check data acquisition system connectivity.

FAQ

1.What is this product?

It is a laboratory test stand for evaluating friction, stick-slip behavior, and potential squeak noise in automotive materials and components.

2.What is this product used for?

To measure static/dynamic friction, stick-slip acceleration, pulse frequency, and friction coefficient under controlled environmental conditions for material selection and design verification.

3.What is the working principle?

A linear motor drives the test head across the sample under controlled load, recording friction force, acceleration, pulse frequency, and friction coefficient. Data is used to predict squeak noise and assess material compatibility.

4.Why is this product important?

It ensures automotive interior and functional materials meet tactile comfort and noise performance requirements, supporting design optimization, material selection, and quality assurance.

5.What industries is this product suitable for?

Automotive interiors, functional components, material R&D, OEM quality control, and third-party testing laboratories.

Leave Message Get Price