Bus Seat Tester

The Bus Seat Tester is designed to evaluate the durability, strength, and fatigue performance of bus seating systems in compliance with FMVSS 222 and NHTSA S5.1.3 / S5.1.4 standards.

Application

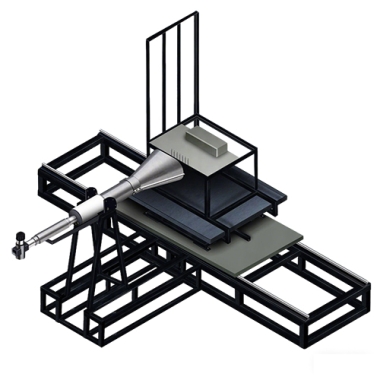

It can be mounted directly to the customer’s existing bedplate or supplied with a dedicated base. All mechanical functions are fully electric, eliminating hydraulic systems, for precise, repeatable testing.

The system is ideal for manufacturers, quality control, and safety compliance laboratories, providing both static and dynamic load testing in tension and compression to simulate real-world usage and safety conditions.

Standards

NHTSA S5.1.3 – Seat Structural Strength Testing

NHTSA S5.1.4 – Seat Attachment Strength Testing

FMVSS 222 – School Bus Seating and Crash Protection Standards

OEM / Internal Durability Specifications – Configurable for specific test requirements

Technical Specifications

| Item | Specification |

|---|---|

| Mechanical Drive | Fully electric, no hydraulic components |

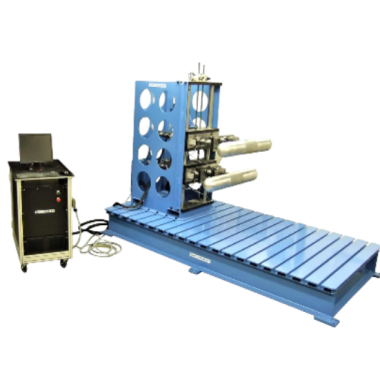

| Shafting | 2½ inch (63.5 mm) diameter solid steel for linear adjustments and rigidity |

| Beam Adjustment | Upper and lower beams manually adjustable in height via crank handles |

| Motion Control | Extend/retract variable speed, programmable through software |

| Control System | PC-based Visual Basic software running on Windows environment |

| Data Acquisition | Load and position data recorded and plotted automatically for each ram |

| Data Output | Graphical results printable on inkjet printer in console; exportable to PC formats |

| Setup & Operation | Simple, intuitive interface; minimal training required for PC-literate operators |

| Power Requirements | 220–240 V.A.C., single phase (typical) |

| Test Capabilities | Static and dynamic tension/compression tests; destructive and non-destructive options |

| Mounting | Can attach to customer’s existing bedplate or supplied with optional bedplate |

Features

Electric-Only Design: Eliminates hydraulic systems for cleaner, more precise operation and reduced maintenance.

High Rigidity Construction: Solid steel shafting ensures minimal deflection during testing.

Adjustable Beams: Manual height adjustment allows flexible accommodation of different seat configurations.

Programmable Motion & Speed: Variable extension/retraction rates via user-friendly PC software.

Integrated Data Acquisition: Automatic plotting and recording of load and position for each test cycle.

Printable & Exportable Results: Graphs can be printed or saved for reporting and analysis.

Simple Setup & Operation: Intuitive software designed for users familiar with standard Windows PC environment.

Versatile Testing: Supports both static and dynamic load applications, including destructive testing scenarios.

Test Procedures

(1) Install and secure the bus seat on the bedplate according to the applicable standard.

(2) Calibrate load and displacement sensors.

(3) Set loading direction, speed, stroke, and target load in the control software.

(4) Start the test and apply load automatically according to the programmed sequence.

(5) The system stops automatically upon reaching specified conditions or structural failure.

(6) Inspect and document seat deformation and failure mode.

(7) Export and archive test data and load–displacement curves.

Maintenance Information

(1) Periodically inspect electric actuators and mechanical connections.

(2) Verify sensor calibration at regular intervals.

(3) Keep guide shafts and mechanical interfaces clean.

(4) Check electrical connections and software operation status.

(5) Store the equipment in a dry laboratory environment.

FAQ

(1) What is this product?

It is a fully electric destructive testing system for evaluating bus and commercial vehicle seat strength and safety.

(2) What is this product used for?

It is used to perform regulatory static and dynamic load tests on seat structures and attachments.

(3) Why is this product important?

It verifies compliance with safety regulations and ensures occupant protection under severe loading conditions.

(4) What industries is this product suitable for?

Automotive manufacturers, seat manufacturers, and third-party testing laboratories.

(5) What types of this product are available?

Configurations compatible with customer bedplates or independent bedplate systems, supporting various load capacities and test setups.

Leave Message Get Price