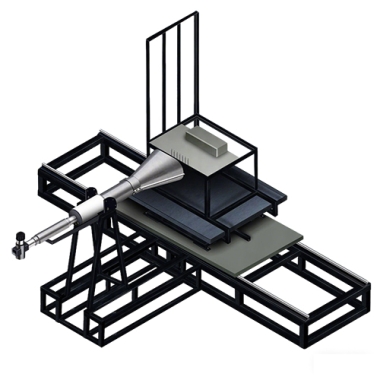

Automobile Headrest Strength Tester

The Automobile Headrest Strength Tester is designed to evaluate the ultimate strength and durability of automotive headrest assemblies in accordance with FMVSS 202 requirements.

Application

It enables simultaneous testing of up to three headrest assemblies on a single bench seat, ensuring compliance with automotive safety and durability standards.

This tester is available in both Hydraulic and Electric configurations and is equipped with a floor-standing, PC-based Control and Data Acquisition System. The system operates on 115 V.A.C. power (other voltages available) and provides precise control, monitoring, and recording of test data.

Standards

(1) FMVSS 202 – Head Restraints: Strength and Positioning Requirements

(2) GB 11550-2009 – Strength Requirements and Test Methods for Automobile Headrests

(3) ECE R17 – Seats, Their Anchorages and Head Restraints

(4) ECE R21 – Interior Fittings (head restraint-related requirements)

Technical Specifications

| Feature | Specification |

|---|---|

| Test Standard | FMVSS 202 |

| Test Purpose | Determine ultimate strength of up to three headrest assemblies |

| Test Capacity | 3 headrest stations (concurrent testing) |

| Configuration Options | Hydraulic or Electric |

| Control System | PC-based Control and Data Acquisition (floor-standing console) |

| Power Supply | 115 V.A.C. (other voltages available) |

| Table Construction | 1-inch (25.4 mm) thick ground steel plate |

| Hole Array | 4-inch (101.6 mm) grid with ½”-13 threaded holes |

| Movement Adjustments | Adjustable height and in/out movement relative to “H” point pivots |

| H-Point Alignment | Center station adjustable vertically and horizontally |

| Lateral Adjustment | Outer stations movable for occupant spacing |

| Locking Mechanism | All set-up movements lockable to prevent displacement |

| Control Valves (Hydraulic model) | Double-solenoid directional valves with compensated regulators |

| Table Lift | Electric motor-driven |

| Operation Speed | Controlled slow movement for real-time observation |

| Data Acquisition | Real-time recording, graphical plotting, and data export |

| Software Interface | Standard pull-down menus for plotting and analysis |

| Data Output | PC file saving, downloading, and color inkjet printout |

Advantages and Features

Complies with FMVSS 202 automotive safety requirements.

Multi-station testing capability for simultaneous evaluation of up to three headrests.

Hydraulic or Electric options to match customer facility preferences.

PC-based control system with data acquisition, real-time monitoring, and result visualization.

Precision-machined steel table with multiple mounting points for flexible test setups.

Accurate H-point positioning for realistic occupant alignment.

User-friendly software suitable for PC-literate technicians.

Data storage and export functions for test traceability and reporting.

Durable and rigid construction for high repeatability and long service life.

Test Procedures

(1) Install the seat and headrest assemblies on the test table and secure all fixtures.

(2) Adjust H-point alignment, height, and lateral spacing according to the standard.

(3) Lock all mechanical adjustments to prevent movement.

(4) Calibrate the load and displacement sensors.

(5) Set test parameters in the PC control software.

(6) Apply static load gradually at the specified loading point.

(7) Record force and displacement data until the target load or failure condition is reached.

(8) Stop the test and save the test data and curves.

FAQ

1. What is this product?

It is a static strength testing system for evaluating automotive seat headrest assemblies.

2. What is this product used for?

You use it to verify headrest strength, durability, and compliance with safety regulations.

3. What is the working principle of this product?

A controlled static load is applied to the headrest while force and displacement are measured in real time.

4. Why is this product important?

It ensures headrests meet regulatory safety requirements and provide effective occupant protection.

5. What industries is this product suitable for?

Automotive manufacturers, seat suppliers, and third-party testing laboratories.

Leave Message Get Price