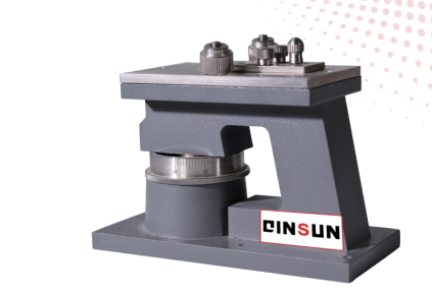

Precision Fiber Slicer

The G214 Precision Fiber Slicer is designed for preparing highly accurate fiber cross-section specimens for microscopic observation, analysis, and research.

Users insert a degreased fiber bundle into the micro-holes at the top of the slicer, fix the sample, set the thickness with the micrometer, and cut precision slices using a blade.

This slicer is suitable for all types of natural and synthetic fibers, producing cross-sections as thin as 10 μm for fineness analysis, morphological study, or quality inspection.

Standards Compliance

The instrument meets multiple international standards for fiber diameter and morphology measurement:

ASTM D2130 – Wool and animal fiber diameter by microprojection

BS 2043 – Hair fiber fineness measurement

DIN 53811 – Textile fiber diameter inspection

ISO 137 – Determination of wool fiber diameter

IWSTM 24, IWTO 8-6 – Wool and animal hair fineness test methods

Major Features

1. Precision Cutting System

Equipped with a precision indexing plate, capable of cutting 10 μm sections.

Ensures highly stable and accurate cross-sectional thickness for microscopic analysis.

2. Quick Loading Fixture

Quick-twist nut design allows rapid installation and securing of fiber bundles.

Improves operational efficiency and reduces preparation time.

3. Compact & Durable Integrated Design

Base, sliding plate, and dial integrated into a compact body.

Simple structure, easy for laboratory and production-line use.

No power supply required; fully manual and extremely reliable.

Applications

The G214 system is ideal for preparing cross-section samples for:

Fiber morphology research

New product performance verification

Production quality control

Third-party testing agencies

Research institutes and quality supervision departments

Applicable to:

Wool, cashmere, animal fibers

Synthetic fibers

Technical fibers requiring precise cross-section evaluation

Technical Parameters

| Item | Specification |

|---|---|

| Trial mode | Manual |

| Metal needle width | 1.5 mm |

| Metal needle thickness | 0.8 mm |

| Slide width | 30 mm |

| Slide length | 60 mm |

| Slide thickness | 3 mm |

| Slot width | 1.5 mm |

| Weight | 3 kg |

| Power supply | None |

| Dimension | 150 × 100 × 150 mm |

Operation Instructions (Optimized Workflow)

Rotate the micrometer wheel to its bottom position.

Unscrew and remove the cover.

Insert the fiber bundle through the slot, leaving a small exposed section.

Tighten the screws and lock the push plate to compress the fiber.

Cut along the cover using a sharp blade (first cut).

Adjust the micrometer to the required slice thickness.

Apply a drop of collodion to fix the fiber.

Cut again along the cover to obtain the final cross-section specimen.

Leave Message Get Price