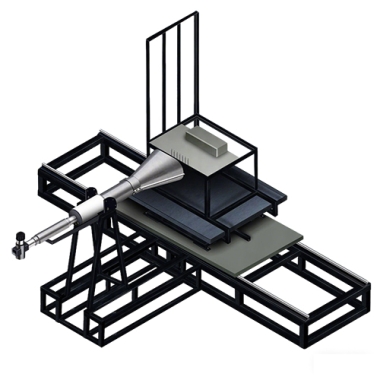

Mobile Electric Turbine Liquid Nitrogen Pump

Main parameter

Liquid nitrogen pumping rate: 0-5 L/min, stepless adjustable

Electric-mechanical turbine design, one-touch liquid nitrogen dispensing, delivery height >3m

Standard configuration: 30L liquid nitrogen container (50mm diameter)

Built-in high-capacity lithium battery with visible power indicator, single charge supports >200L liquid nitrogen transfer

No power outlet required, unrestricted mobility with silent universal base

Mechanical turbine advantages over pneumatic pumps:

① No air contamination from injection

② Seal-free design eliminates overpressure risks

③ Faster liquid nitrogen dispensing via one-touch operation

Technical background

For open-mouth liquid nitrogen containers commonly used in laboratories, transferring liquid nitrogen to target vessels typically involves:

◆ Method 1: Manual tilting/pouring

Disadvantages:

① Labor-intensive: Especially for containers over 30L, single-operator handling is impractical

② Safety hazards: Uncontrolled flow rate causes splashing/overflow risks, exposing personnel to cryogenic hazards

◆ Method 2: Pneumatic liquid nitrogen pump

Disadvantages:

① Slow delivery: Requires manual/electric air pump to inject air into the container. Liquid nitrogen only discharges when internal pressure reaches threshold, resulting in significant lag and low efficiency

② Contamination risk: Injected air contains oxygen, CO₂, and moisture that pollute the liquid nitrogen. Air-contaminated (particularly oxygen-dissolved) liquid nitrogen experiences temperature elevation, compromising applications requiring stable cryogenic conditions

This utility model patent employs a cryogenic-resistant turbine that utilizes centrifugal force for pumping, powered by a brushless DC motor and high-capacity lithium battery. The stepless adjustable pumping speed overcomes multiple drawbacks of conventional pumps, providing contamination-free, rapid liquid nitrogen transfer in a user-friendly design.

Leave Message Get Price