-

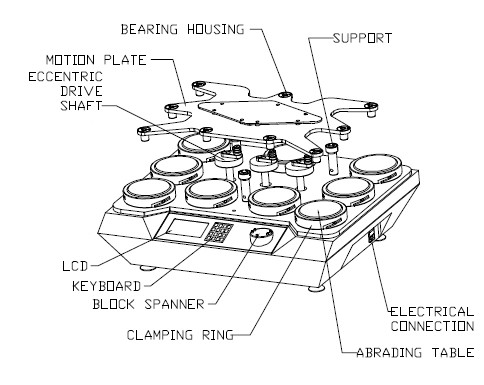

Martindale abrasion tester for testing the abrasion resistance of fabrics in three main test solutions

Edited by:Read:The Martindale abrasion tester is used to test the abrasion and pilling properties of textiles, woollen textiles, artificial leather and synthetic leather under pressure.

The Martindale abrasion tester tests the abrasion resistance of fabrics in three main test protocols.

Mass loss assay:

This tester is suitable for all textile fabrics, but not for fabrics with a short wear life. The requirements for the determination are the same as for the specimen breakage method with regard to the choice of abrasive, the sampling method, the choice of the specimen jig liner, the choice of the total effective mass of the friction load and the abrasive replacement interval.

(1) Inspection interval

A suitable inspection interval is designed as an observation point for the wear state of the specimen surface during the specimen wear resistance test, with the inspection interval being a certain number of friction times. During the test the specimen is checked for wear at the set inspection interval and the test is completed when the specimen is broken or has reached the required number of rubs. The loss of mass is measured in two ways: in one case, at each inspection interval, the difference between the mass of the specimen before the test and the mass of the test sample after the wear test is measured Δmi; in the other case, the specimen reaches the wear point and the difference between the mass of the specimen before the test and the mass of the test sample after the wear test is measured Δm.

(2) Test results

Using the method of measuring the abrasion resistance of fabrics one-by-one with respect to mass loss, the test results include the following data.

1) The measured mass loss Δmi. at each inspection interval;

2) the mass loss Δmi at the point of wear of the specimen, i.e. at the end of the test;

3) wear index Ai (times/g), calculated as

Ai=N/Δmi;

N i is the total number of friction times.

Change in appearance mass method:

The change in appearance quality method is suitable for textile fabrics with a short wear life. The selection of the abrasive, the sampling method and the selection of the specimen jig liner are consistent with the method of determining the breakage of the fabric specimen.

(1) Total effective mass of the friction load (198±2) g;

(2) Abrasive replacement cycle: new foam and standard abrasives for each test;

(3) Assessment of changes in the appearance of the specimen provides for.

1)Wear test to the surface change specified in the protocol, using the number of rubs as the measured value of wear resistance. Design appropriate inspection intervals as observation points for changes in specimen appearance.

(2) Martindale abrasion testing machine to the agreed number of rubs, assessing the change in specimen surface by comparison with an untested sample of the same fabric.

(4) Test results: Surface changes include discolouration, pilling and pilling. If the end point of the abrasion test is to achieve the surface change specified in the agreement, the test protocol shall specify the surface discolouration, pilling and pilling degree level of the specimen, and the test result shall be expressed by the number of times the specimen is rubbed when it reaches the discolouration, pilling and pilling degree level specified in the test protocol. If the end point of the abrasion test is the number of rubs specified in the agreement, the test result is the comparison of the post-test sample with the original sample after the abrasion test has reached the specified number of rubs, and the rating of the degree of discolouration, pilling and pilling of the post-test sample, using the grade of discolouration, pilling and pilling of the post-test sample to explain the change in appearance quality.

Specimen breakage determination method

This method is applicable to all textile fabrics, but not to fabrics with a short wear life.

(1) Selection of abrasives. Different standard abrasives are selected according to the characteristics of the specimen. Uncoated fabric: woven plain wool fabric; coated fabric: No.600 water abrasive paper. The abrasive and the abrasive table are separated by wool felt. After the test, the surface of the felt is inspected and should be replaced in time if it appears stained or worn.

(2) Sampling method. At least 3 pieces, Xiang L fabric should contain different warp and weft yarns. Jacquard fabric or fancy tissue, should include a complete tissue of each characteristic part, a complete tissue or pattern is larger, each part can be sampled separately.

(3) Selection of specimen jig liner. Determination of the mass of the unit area of the specimen, the unit area of the specimen ≧ 500g/m2, no foam liner, the unit area of the specimen: 500g/m2, the specimen fixture with foam liner, each test to replace the foam liner.

(4) The total effective mass of the friction load is selected. The total effective mass of the friction load includes the gripper, the stainless steel disc, and the mass of the specimen weight. According to the technical parameters provided by the Martindale Abrasion and Pilling Tester, the gripper mass is 200±1)g; the stainless steel disc mass is 260±1)g; the specimen weight mass is 395±2)g, (594±2)g.

According to the specimen use, the fabric characteristics to choose the corresponding friction load total effective mass of three.

1) (795±7)g: for workwear, furniture decoration cloth, bed linen products, industrial fabrics;

2) (595±7)g: for taking and home textiles (furniture upholstery, bed linen products), non-taking coated fabrics;

3) (198±2)g: for coated fabrics for taking.

(5) Abrasive replacement cycle

Wool standard fabric: 50,000 times; standard water sandpaper: 6,000 times.

(6) Inspection interval

The number of times the specimen is rubbed when it reaches breakage is predicted, and on this basis an appropriate inspection interval is designed as an observation point for the wear state of the specimen surface during the specimen wear resistance test, with the inspection interval being a certain number of rubs.

(7) Measurement results representation

The total number of rubbing times for each specimen when it breaks is measured, and the number of rubbing times accumulated before the specimen breaks is taken as the wear resistance number.

The above are the three main methods of Martindale abrasion tester to detect the abrasion resistance of fabrics summarized for you by QINSUN R&D engineers. Click here to get more information about Martindale abrasion test.

- 2024-04-19Paper ring compression strength tester standards

- 2024-04-19Cupping tester standards

- 2024-04-19Rubber and plastic tensile tester standards

- 2024-04-19Taber 1750 wear-resistant tester standards

- 2024-04-19Stone Chip Resistance Gravelometer standards

- 2024-04-18Diaper absorption speed tester standards

- 2024-04-18Diaper leakage tester technical indicators

- 2024-04-18Paint film impact resistance tester standards

- 2024-04-18Low temperature brittleness tester principle

- 2024-04-18Battery separator permeability tester technical indicators