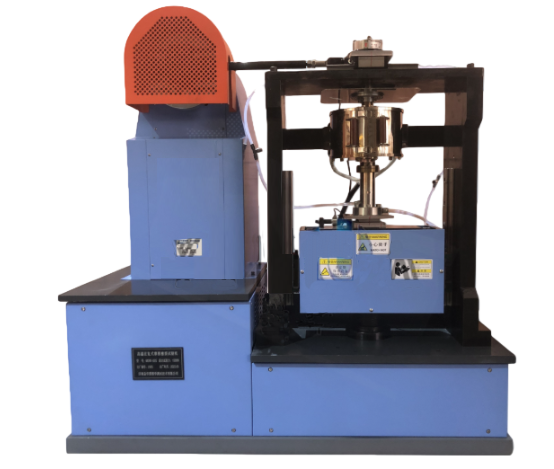

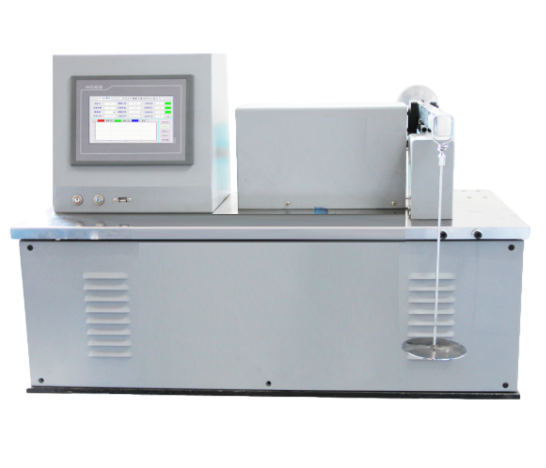

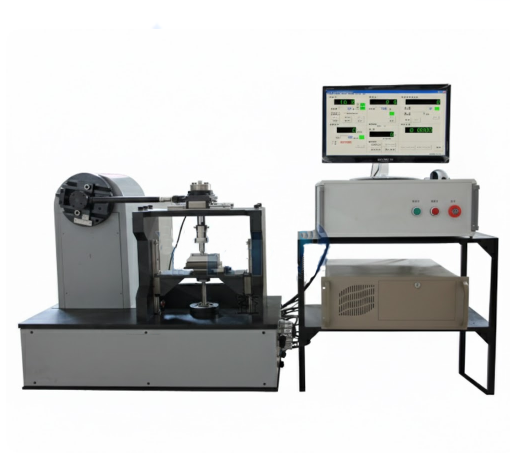

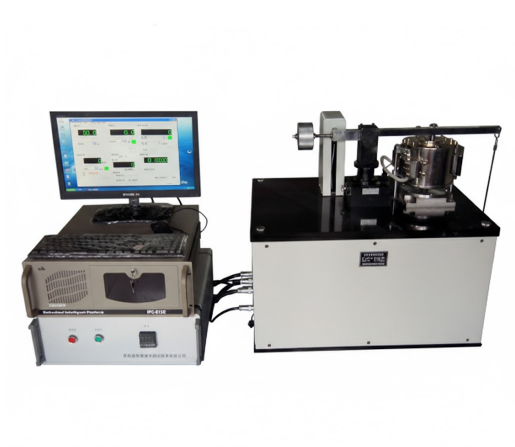

High-Temperature Tribology Tester

The High-Temperature Tribology Tester is designed to perform friction and wear tests using ball-on-disk and pin-on-disk configurations. It is suitable for simulating dry friction, oil lubrication, and high-temperature friction conditions. The device integrates a test force loading system, friction measurement system, sample fixture, high-temperature heating system, and temperature control system. By adjusting temperature, load, speed, and friction pair materials, you can comprehensively evaluate wear resistance and lubrication performance under varied conditions.

Applications

You can use this tester for:

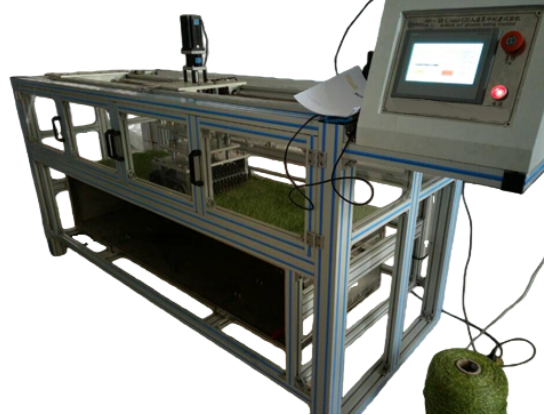

High-temperature friction and wear testing of metals, ceramics, and polymer materials

Friction tests under different lubrication states, including oils and gases

Dry, oil-lubricated, and gas-lubricated tests at elevated temperatures

Comparative wear evaluation and material performance assessment in high-temperature environments

Industrial product development, material selection, and quality control

Standards

ASTM G99: Standard Test Method for Wear Testing

ASTM G133: High-Temperature Friction and Wear Test Method

ISO 20808: Solid Material Friction and Wear Test

GB/T 3147: Methods for Determining Friction Material Wear Performance

Technical Specifications

| Parameter | Range / Specification |

|---|---|

| Test Force Loading Range | 0.1–10 N, 10–200 N |

| Maximum Friction Torque | 2.5 Nm |

| Spindle Maximum Speed | 2000 rpm |

| Heating Temperature Range | Room temperature – 1000℃ |

| X-Axis Adjustable Friction Radius | 0–35 mm |

| Z-Axis Adjustable Lift Height | 0–50 mm |

| Test Medium | Dry friction, circulating gases (N₂, CO₂, He, Ar, etc.), oil |

| Time Display & Control | 0–999999 s/min |

| Revolution Display & Control | 0–999999999 r |

| Machine Weight | Approx. 90 kg |

| Power Supply | 220 V, 16 A |

| Power | 1.5 kW |

Features

Dual Friction Modes: Supports ball-on-disk and pin-on-disk testing to meet different experimental requirements

High-Temperature Capability: Adjustable up to 1000℃ for testing high-temperature materials

Multiple Lubrication Options: Dry, oil, or inert gas lubrication (N₂, CO₂, etc.)

High-Precision Control: Accurate temperature control and force measurement ensure reliable testing

Adjustable Friction Radius and Height: Flexible X-axis radius and Z-axis lift height for customized testing

Long-Term Operation: Capable of prolonged high-temperature and high-load tests in demanding environments

Accessories & Consumables

| Name | Description |

|---|---|

| High-Temperature Furnace | Provides heating from room temperature up to 1000℃ |

| Friction Disks & Balls | For ball-on-disk and pin-on-disk tests |

| Lubricating Oils | Used for oil-lubricated tests |

| Inert Gases (N₂, CO₂, etc.) | Used for gas-lubricated tests |

| Sample Fixtures | Secures the test samples |

| Thermocouples | Measure friction pair temperature during testing |

Testing Principle

The tester simulates friction behavior of samples under normal or elevated temperatures. By applying loads and varying speed, temperature, and lubrication conditions, you can evaluate the friction and wear performance of materials. The ball-on-disk or pin-on-disk contact generates friction, and measurements of friction force and wear allow you to assess material wear resistance and lubrication efficiency.

Operation Instructions

Installation & Inspection: Ensure all connections are secure, power supply is correct, and temperature and friction sensors are calibrated.

Sample Preparation: Prepare friction pair materials and lubricants as required, and secure samples.

Set Parameters: Use the touchscreen to set temperature, load, friction speed, and friction pair material.

Start Test: Confirm settings and start the experiment, monitoring data throughout the process.

Record & Analyze: After testing, save the data and perform analysis to calculate friction and wear performance according to standards.

Experimental Procedure

Set Test Conditions: Choose friction pair, temperature, load, and other parameters according to the test standard.

Prepare Friction Pairs: Install disks and balls/pins, adjusting friction radius and height as required.

Activate Heating System: Set target temperature and allow the system to stabilize.

Begin Testing: Start the experiment, recording friction force, temperature, and wear data.

End Test & Data Recording: After completion, record all data and analyze friction and wear indicators.

FAQ

1.What is this product?

You are using a High-Temperature Tribology Tester, designed to evaluate friction and wear performance under elevated temperature conditions.

2.What is this product used for?

You can simulate dry, oil-lubricated, or gas-lubricated friction at high temperatures to assess wear resistance and lubrication efficiency.

3.Why is this product important?

It allows you to test materials and lubricants under conditions that replicate real high-temperature operating environments, providing reliable performance data.

4.What industries is this product suitable for?

You can use it in materials research, high-temperature tribology studies, industrial product development, lubrication testing, and quality control labs.

5.What types of this product are available?

You can configure it with ball-on-disk or pin-on-disk modes, adjustable temperature, load, friction radius, and lubrication options for customized high-temperature testing.

Leave Message Get Price