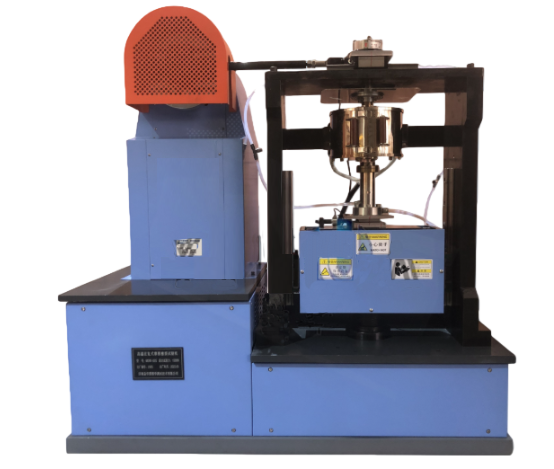

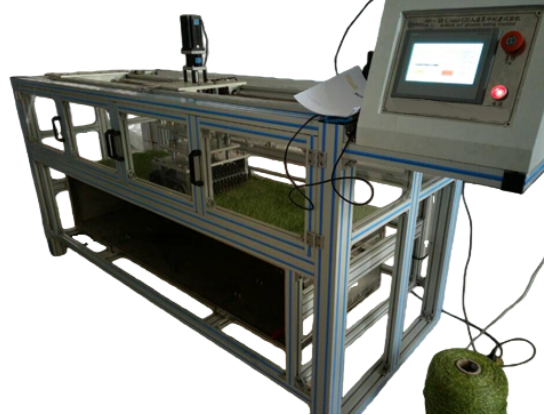

Flame Penetration Fuel Test System

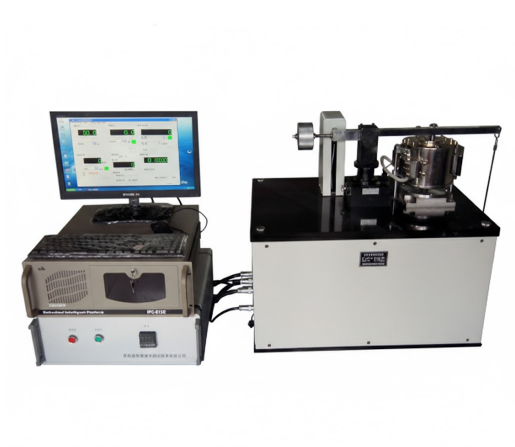

The Flame Penetration Fuel Test System for Thermal and Acoustic Insulation Materials is a dedicated fire testing platform designed to evaluate flame penetration behavior, combustion performance, and thermal response of aerospace insulation materials under controlled aviation fuel fire exposure. The system integrates the FAA-approved NexGen aviation fuel burner with a specialized flame penetration test apparatus and a dynamic loading motion system, enabling realistic simulation of aircraft fire scenarios while accurately controlling and monitoring fuel and air parameters. The modular design supports both current testing requirements and future FAA technical upgrades.

Application

This system is applicable to aviation fuel fire testing of a wide range of aerospace materials, particularly those used in aircraft cabin structures and thermal management systems, including:

Thermal insulation materials

Acoustic insulation materials

Composite sandwich panels

Cabin wall panels

Ceiling liners

Interior partitions

Fire barrier layers

Multi-layer insulation assemblies

The NexGen burner provides standardized aviation fuel flame exposure, while the configured flame penetration apparatus enables direct assessment of whether flames can penetrate insulation layers under high-temperature conditions.

Standards

The system is compatible with the following international aerospace fire testing standards:

BSS 7387 – Flame spread and combustion behavior of aerospace materials

AITM 2.0056 – Heat release rate measurement of aerospace materials using cone calorimeter

FAR Part 25 Appendix F Part VII – Heat release and fire performance requirements for aircraft cabin materials

Parameters

| Item | Specification |

|---|---|

| Overall dimensions | 1500 mm (W) × 1800 mm (H) × 900 mm |

| System weight | 150 kg |

| Power requirement | 220 V, 10 A |

| Operating temperature | 10°C to 35°C |

| Fuel type | Aviation kerosene |

| Air supply | Minimum 120 PSI compressed air |

| Flame temperature capability | ≥ 2000 ± 50 ℉ |

| Heat flux output | ≥ 10.6 W/cm² |

| Temperature control bath | ≥ 2 × 0.14 m³ |

Features

Incorporates the FAA-approved NexGen aviation fuel burner, developed to replace discontinued legacy burners (Park DPL 3400. Lennox OB-32. Carlin 200 CRD).

Retains the operational principles of previous burner generations while enabling more precise measurement of fuel and air test parameters.

Modular architecture facilitates future FAA upgrades without full system replacement.

The burner cone is fabricated from corrosion-resistant and high-temperature alloy to ensure durability in severe thermal conditions.

The NexGen burner includes key components such as baffle, fuel nozzle, igniter, fuel rail, mounting plates, ventilation duct, housing, muffler, and acoustic resistance unit.

Equipped with fuel pressure gauge, fuel solenoid valve, fuel temperature sensor, air pressure regulator, and air temperature sensor for stable control.

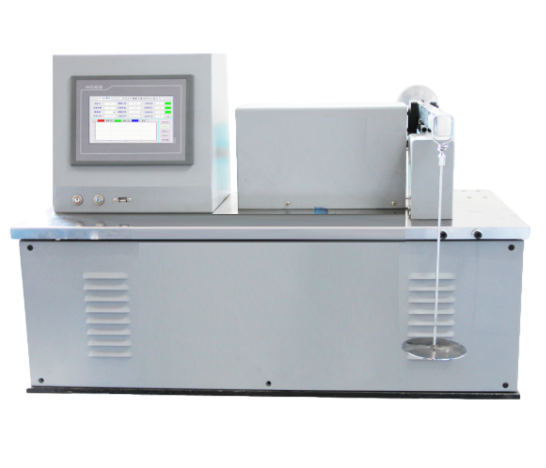

A temperature-controlled ice bath system (≥ 2 × 0.14 m³) allows regulation of fuel temperature prior to combustion.

Flame characteristics can be adjusted by modifying fuel nozzle configuration and air pressure input to meet different standard requirements.

The burner is covered with a thermal insulation blanket to protect fuel lines and the burner body.

Capable of delivering flame temperature of at least 2000 ± 50 ℉ and heat flux of at least 10.6 W/cm².

Mounted on a heavy-duty steel frame that supports both horizontal and vertical specimen installation.

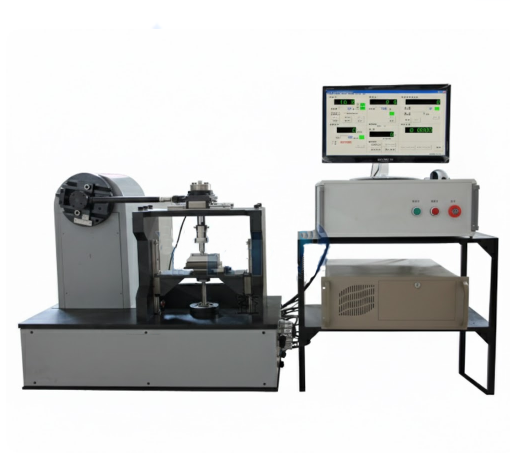

Calibration utilizes a thermocouple comb composed of seven grounded K-type thermocouples (1.6 mm diameter, ceramic-insulated, metal-sheathed, 30 AWG wire), fixed on an angle bracket for standardized placement on the specimen frame.

Includes a radiant heat flux sensor with cooling system, installed on a fixed support bracket for reliable measurement.

Accessories

The system is supplied with the following components:

NexGen aviation fuel burner

Flame penetration test fixture for thermal and acoustic insulation

Dynamic loading motion system

Fuel temperature control ice bath

Thermocouple calibration comb

Radiant heat flux sensor with cooling unit

Heavy-duty specimen mounting frame

Burner thermal insulation blanket

Test Procedures

Mount the test specimen on the horizontal or vertical frame according to the selected standard.

Connect aviation kerosene supply and compressed air (≥120 PSI).

Set and stabilize fuel temperature using the ice bath system.

Adjust air pressure and fuel flow parameters per test requirements.

Ignite the NexGen burner and allow the flame to stabilize.

Position the flame relative to the specimen and initiate exposure.

Monitor flame temperature and heat flux using thermocouples and sensors.

Observe whether flame penetrates the insulation material within the specified time.

Record data and evaluate performance in accordance with the applicable standard.

Maintenance Information

To ensure long-term reliability and compliance:

Clean the fuel nozzle regularly to prevent blockage.

Inspect fuel lines and valves for leakage before each test.

Calibrate thermocouples and heat flux sensors periodically.

Replace the burner insulation blanket if damaged or degraded.

Maintain proper ventilation in the test area.

Keep the compressed air system dry and free from oil contamination.

FAQ

1. What is the core advantage of this product?

The main advantage is the use of the FAA-approved NexGen burner, which provides higher measurement accuracy, better repeatability, and built-in capability for future regulatory upgrades.

2. Are the test results reliable?

Yes. The system employs calibrated thermocouples, controlled fuel temperature, stable air pressure regulation, and standardized heat flux measurement, ensuring high repeatability and traceability of results.

3. Which international/industry standards does it comply with?

The system supports testing in accordance with BSS 7387. AITM 2.0056. and FAR Part 25 Appendix F Part VII.

4. Why is this product important?

It enables realistic evaluation of flame penetration risk in aircraft insulation materials, directly supporting aviation safety certification, material qualification, and regulatory compliance.

5. Which fields is this product suitable for?

The system is appropriate for:

Aerospace testing laboratories

Aircraft manufacturers

Aviation material suppliers

Certification and regulatory bodies

Fire research institutes

Composite and insulation material R&D centers

Leave Message Get Price