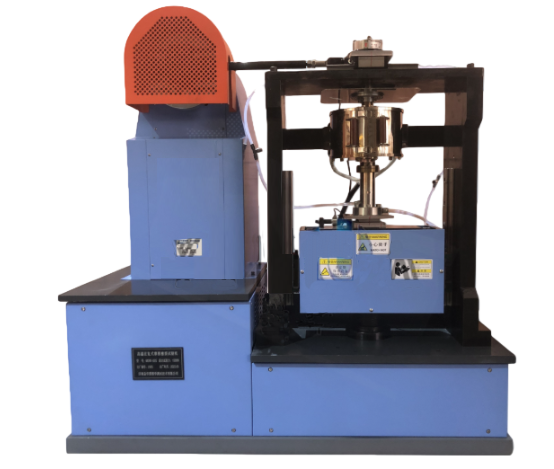

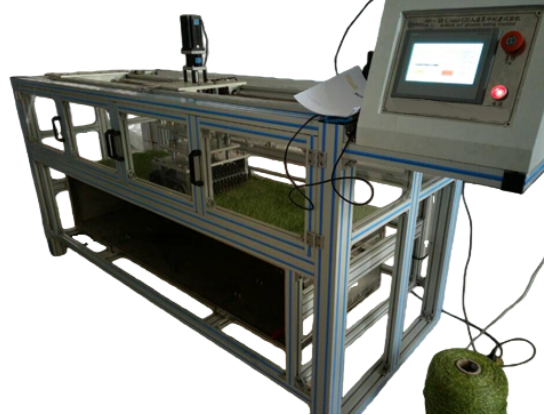

Full-Scale Room Corner Fire Test Apparatus

The Full-Scale Room Corner Fire Test Apparatus is designed to evaluate the combustion performance of surface materials under full-scale room fire conditions. Based on the oxygen consumption principle, it follows the GB/T 25207-2010 standard, which refers to ISO 9705. You can simulate a realistic corner fire scenario with actual installation conditions for the test samples, providing the most reliable assessment of flame spread, smoke production, and heat release rate. This apparatus is widely used in fire science research and for materials that cannot be accurately assessed using small-scale tests.

Application

You can use this apparatus in the following scenarios:

Full-scale fire performance evaluation: Assess the fire behavior of wall and ceiling materials installed as in real applications.

Research and development: Study flame spread, smoke generation, and heat release of construction and decorative materials.

Fire safety certification: Evaluate materials for compliance with building codes and international fire safety standards.

Academic and scientific research: Investigate fire dynamics and corner fire phenomena that small-scale tests cannot replicate.

Compatible test components: Combustion chamber, smoke and sample gas collection system, gas analysis and data processing system, fuel supply system, sand-box burner.

Standards

This test apparatus conforms to a range of international and national standards:

GB/T 27904:2011 — Test method for flame spread of interior decoration materials

GB/T 25207:2010 — Classification of fire performance of building decorative materials

GB 8624:2012 — Classification of the burning behavior of building materials and products

ISO 9705:2016 — Full-scale room corner test for building materials

DS/ISO/TR 9705‑2 — Room corner fire test Part 2: Guidelines for material performance assessment

Parameters

| Parameter | Specification |

|---|---|

| Combustion Chamber Size | 2.4 m (L) × 3.6 m (H) × 2.4 m (W) |

| Smoke Hood Size | 3 m (W) × 3 m (D) × 1 m (H) |

| Weight | 700 kg |

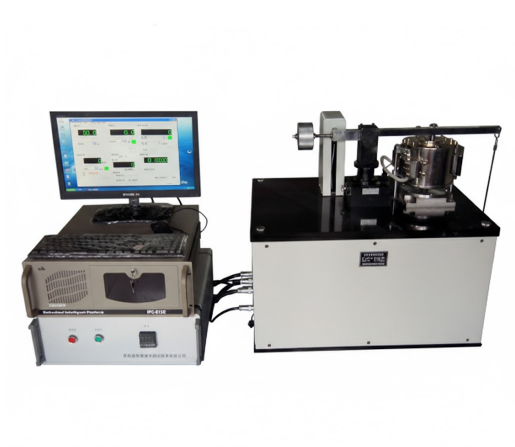

| Sand-box Burner | Corner installation with 4–8 mm gravel and 2–3 mm sand, top surface flush with burner edge |

| Burner Ignition | Surface ignition (no electric spark) |

| Maximum Heat Output | 300 kW |

| Mass Flow Controller Range | 0–7 g/s, accuracy ≤1.5% |

| Smoke Sampling Flow | ≥13 L/min (diaphragm pump) |

| Optical Measurement Range | 400–750 nm, transmissivity accuracy 0.01% |

| Pressure Measurement | ±200 Pa, sensor response ≤1 s |

| Oxygen Analysis | Paramagnetic, 16–21% (V/V), response ≤12 s |

| Carbon Dioxide Analysis | IR type, 0–10% CO2. linearity ≤1%, response ≤12 s |

| Data Recording Interval | 3 s per record |

| Environmental Requirements | Power: 220V/10A, 380V/5KW; Temp: 10–35°C; Gas: propane, calibration gases: N2. CO2 |

Features

Complete system: Includes combustion chamber, smoke and sample gas collection, gas analysis and data processing, and fuel supply systems.

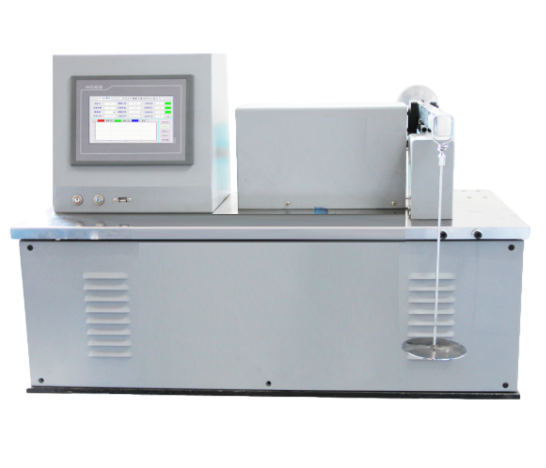

Precision smoke collection: Conical hood with mixing devices ensures uniform smoke sampling and accurate gas analysis.

High-capacity exhaust: Stainless steel centrifugal fan, temperature-resistant to 300°C, adjustable flow rate ≥3.5 m/s.

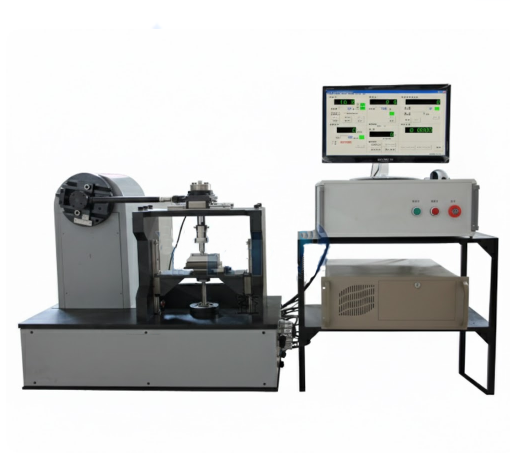

Accurate mass and gas flow measurement: Mass flow controllers for propane and air ensure precise heat output.

Advanced optical and gas analysis: Measures O2. CO2. smoke density, and visible light transmissivity with high accuracy.

Realistic fire simulation: Sand-box burner mimics corner fire conditions with adjustable heat output from 100 kW to 300 kW.

Safety protection: UV flame monitoring and automatic shutdown prevent system hazards.

Integrated data acquisition: Records temperature, pressure, smoke density, and gas concentration in real time; includes software for calibration, analysis, and report generation.

Accessories

Combustion chamber with corner sand-box burner

Smoke collection hood and stainless steel ducting with mixing devices

Gas analysis system (O2 and CO2 analyzers)

Data acquisition and processing system with computer and printer

Mass flow controllers and calibration gases (N2. CO2)

Optical measurement system and thermocouples

Pressure sensors and smoke density measurement system

Test Procedures

Install materials in the combustion chamber according to their real-life application layout.

Connect propane fuel and calibration gases, and ensure all sensors and measurement devices are operational.

Ignite the sand-box burner and control gas flow to produce 100 kW heat output for the first 10 minutes.

If no flashover occurs, increase heat output to 300 kW and continue for another 10 minutes.

Monitor flame spread, heat release rate, smoke production, and oxygen/CO2 levels in real time.

Stop the test immediately upon observing flashover or after the 20-minute test period.

Analyze and export results using the integrated software.

Maintenance Information

Inspect and clean the combustion chamber, sand-box burner, and exhaust ducts regularly.

Calibrate O2 and CO2 analyzers, optical systems, and mass flow controllers periodically.

Check thermocouples, pressure sensors, and smoke sampling systems before each test.

Ensure exhaust fans and ducting are free of obstructions and capable of continuous operation.

Store propane and calibration gases according to safety regulations, and maintain ambient temperature within 10–35°C.

FAQ

1. What is this product?

It is a full-scale room corner fire test apparatus designed to evaluate flame spread, smoke production, and heat release of surface materials under realistic corner fire conditions.

2. What is it used for?

You can use it to study fire behavior, validate building materials for safety compliance, and conduct fire science research that small-scale tests cannot replicate.

3. How does it work?

A sand-box burner in the room corner simulates a fire, while sensors record heat release, smoke generation, gas concentrations, and temperature. Data is collected and analyzed to assess material performance.

4. Why is it important?

This apparatus provides the most reliable full-scale evaluation of building materials, helping you ensure fire safety and compliance with national and international standards.

5. Which industries is it suitable for?

Construction materials, interior decoration, fire safety research, building code testing laboratories, and academic fire science studies.

Leave Message Get Price