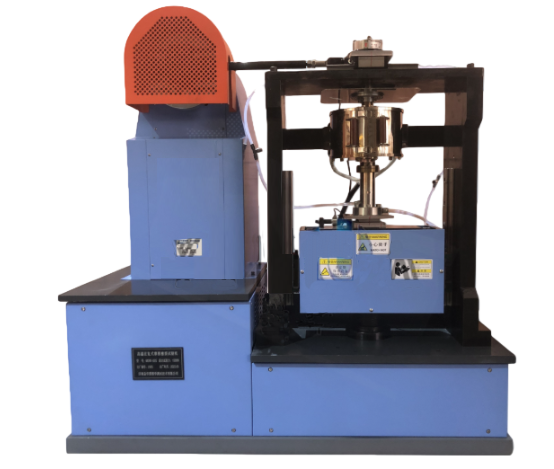

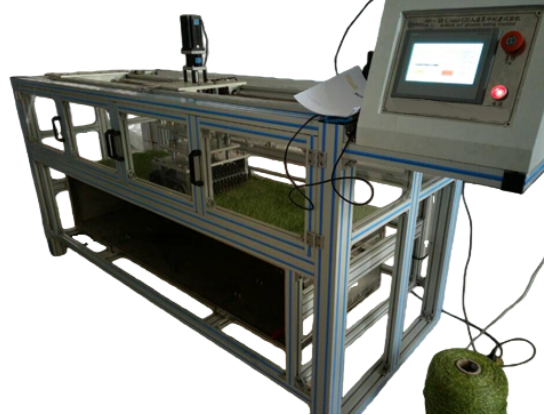

Large Cone Calorimeter

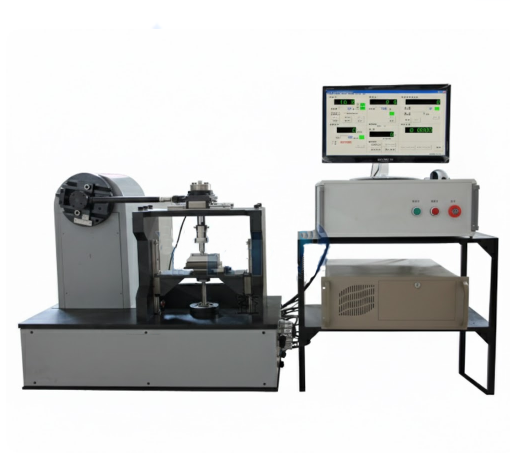

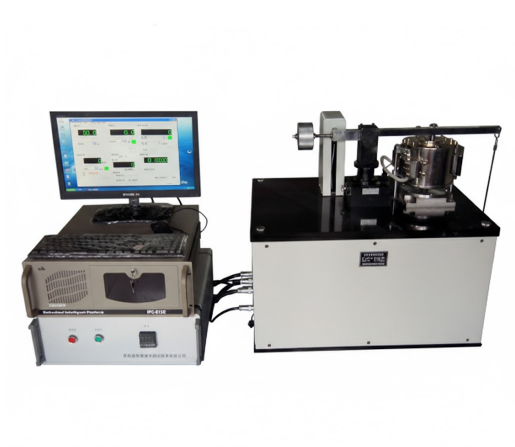

The Large Cone Calorimeter with Variable Atmosphere is designed to measure the heat release rate of materials based on the oxygen consumption principle. You can accurately determine material combustibility, ignition time, mass loss rate, and derived data such as effective heat of combustion and specific extinction area. During testing, samples are placed on a loading unit, heated, and ignited with an electric spark. Combustion gases are collected through exhaust and adsorption ducts, and parameters such as gas concentration, pressure, temperature, and smoke density are automatically recorded. This instrument provides a safe, fast, and reliable method for material development, fire research, and quality control.

Application

You can apply this apparatus in the following scenarios:

Material development: Evaluate thermal and combustion properties of building, decorative, or industrial materials.

Fire safety research: Study heat release, smoke generation, and flame propagation under controlled atmospheres.

Quality control: Monitor material performance to ensure compliance with fire safety standards.

Automotive and transportation: Assess heat release and smoke production of interior materials under varying atmospheric conditions.

Compatible test components: Loading unit, electric spark ignition system, exhaust and adsorption ducts, optical smoke measurement system, mass balance, data acquisition and processing software.

Standards

This apparatus conforms to the following international and national standards:

GB/T 16172‑2007 — Determination of heat release rate and total heat release of building materials and products (Cone Calorimeter Method)

ISO 5660‑1 — Heat release, smoke production, and mass loss measurement for building materials (Cone Calorimeter Method, Part 1)

ISO 5660‑2 — Heat release, smoke production, and mass loss measurement (Part 2: Flame spread testing)

ISO 5660‑4 — Heat release and smoke generation test for automotive interior materials

ISO 5660‑5 — Heat release, smoke production, and mass loss measurement: Additional assessment requirements

ASTM E1354 — Cone calorimeter method for heat release rate and visible smoke release

ASTM E2965 — Guidelines for assessing material combustibility using oxygen consumption

Parameters

| Parameter | Specification |

|---|---|

| Dimensions | 2135 × 915 × 2810 mm |

| Weight | 650 kg |

| Mass Balance Range | 6000 g, resolution 0.01 g |

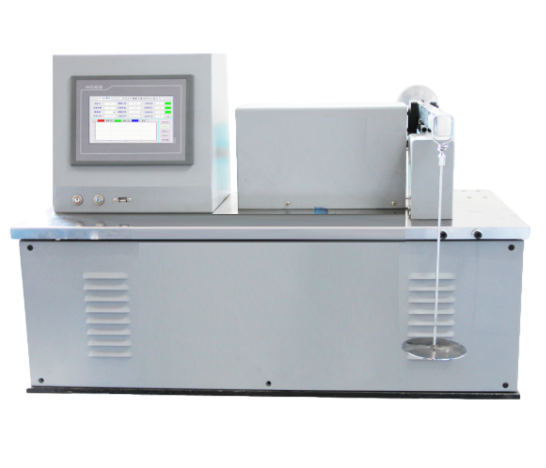

| Gas Analysis | German Siemens analyzer, high precision |

| Exhaust System | Condensation-type smoke treatment with triple filtration |

| Material Handling | Sample loading unit with automated placement |

| Software | Integrated data acquisition and analysis system |

| Operating Gas | Compressed air |

| Calibration Gases | Methane, N2. CO2/CO mixed gas |

| Power Requirement | 220V / 380V, 50 Amps |

| Operating Temperature | 10–35°C |

Features

Integrated computer and acquisition system: Streamlines data collection and analysis.

Durable stainless steel housing: Ensures long-term stability and corrosion resistance.

Triple filtration system: Effectively cleans exhaust gases and protects sensors.

High-resolution mass balance: Measures sample mass loss accurately with 0.01 g resolution.

High-precision gas analysis: Siemens analyzer provides reliable measurement of combustion gases.

Condensation-type smoke treatment: Efficiently collects and condenses combustion gases.

User-friendly operation: No need to manually remove or insert optical filters during testing.

Robust main filter: Stainless steel housing ensures durability and easy maintenance.

Accessories

Loading unit with automated sample placement

Electric spark ignition system

Condensation and exhaust duct system with triple filtration

Optical smoke measurement system

High-precision mass balance

Gas analysis system (Siemens analyzer)

Data acquisition and integrated software system

Calibration gases: Methane, N2. CO2/CO mixture

Test Procedures

Install the sample on the loading unit and ensure proper positioning.

Connect compressed air and calibration gas supplies.

Set the cone heater to the desired heat flux and ignite the sample using the electric spark system.

Measure mass loss, gas concentration, temperature, and smoke density during combustion.

Data is automatically recorded and processed to calculate heat release rate, effective heat of combustion, and derived parameters.

After testing, safely remove the sample and perform routine cleaning of the exhaust and measurement systems.

Maintenance Information

Clean the cone heater, exhaust ducts, and filters regularly to maintain measurement accuracy.

Calibrate the mass balance, gas analyzers, and optical smoke measurement system periodically.

Inspect the sample loading unit and ignition system before each test.

Ensure the exhaust system and filtration components are unobstructed.

Maintain ambient temperature between 10–35°C and verify gas supply pressures before operation.

FAQ

1. What is this product?

It is a large cone calorimeter with variable atmosphere, designed to measure heat release rate, smoke generation, and combustion characteristics of materials under controlled conditions.

2. What is it used for?

You can use it to study material flammability, fire performance, smoke density, and derived combustion parameters for development, safety research, and quality control.

3. How does it work?

Samples are heated and ignited on a loading unit. Combustion gases are collected, and sensors measure oxygen consumption, temperature, gas concentrations, and smoke density. The software calculates heat release rate and other combustion characteristics.

4. Why is it important?

This apparatus provides accurate, reliable, and repeatable measurements of material fire performance, supporting safe design, compliance with standards, and effective quality control.

5. Which industries is it suitable for?

Building materials, decorative products, automotive interior materials, fire safety research, product development, and quality control laboratories.

Leave Message Get Price