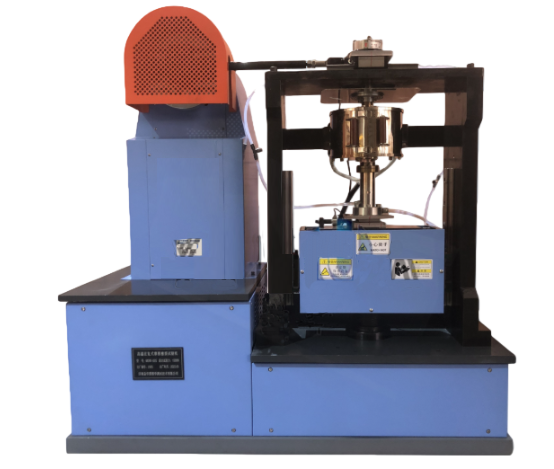

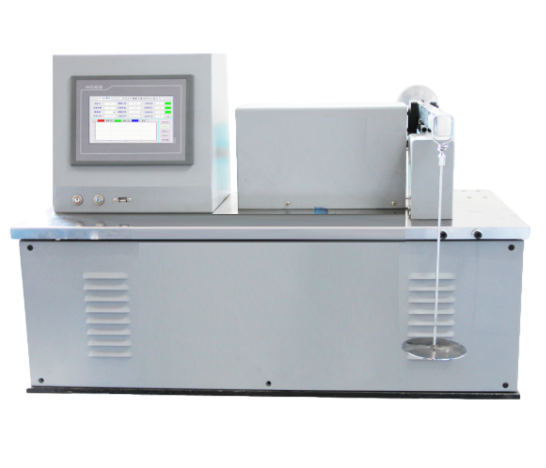

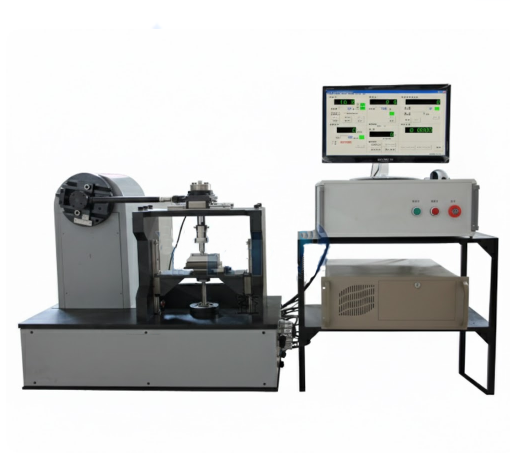

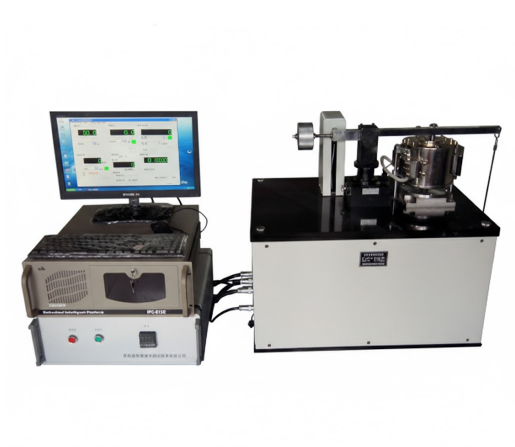

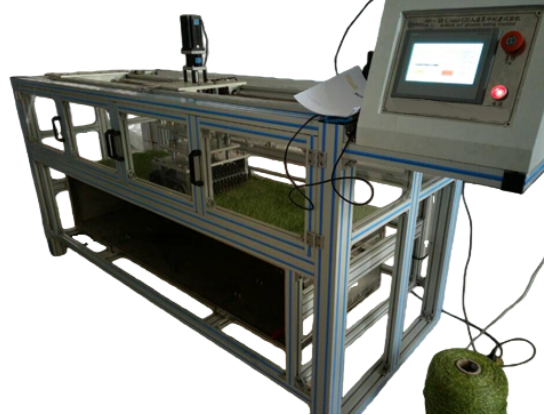

Flame Spread Index Tester

The Flame Spread Index Tester is designed to evaluate the flame propagation characteristics of wall and ceiling lining materials. You can measure the material’s flame spread index (FSI) by exposing samples to a controlled tubular burner with a heat output of 530 J/s and monitoring the flame development over time. This tester allows you to assess fire performance accurately according to international and national standards, providing critical data for building safety, material development, and regulatory compliance.

Application

You can apply this tester in the following scenarios:

Building materials evaluation: Assess the flame spread index of wall and ceiling lining materials.

Plastic material testing: Determine vertical and horizontal flame propagation for polymer materials.

Fire safety compliance: Evaluate materials for civil, railway, and aerospace interior standards.

Quality control: Monitor production materials to ensure consistent fire performance.

Compatible test components: Tubular burner, quartz heaters, T-shaped burner, sample holders, thermocouples, and integrated computer data acquisition system.

Standards

This tester conforms to the following international and national standards:

GB/T 8624‑2012 — Classification of burning behavior of building materials and products (Flame spread index basis)

GB/T 2406.2‑2009 — Plastics combustion test, vertical burning method

GB/T 2408‑2008 — Plastics combustion test, horizontal burning method

GB/T 27904‑2011 — Flame spread test for interior decoration materials

GB/T 16172‑2007 — Determination of heat release rate and total heat release (Cone calorimeter method)

ISO 5658‑2 — Determination of flame spread index, Part 2: Small flame spread test

ISO/TR 9705‑2 — Room corner flame spread test, Part 2: Material performance evaluation

ISO 5660‑2 — Heat release rate, smoke production, and mass loss, Part 2: Flame spread method

ISO 5660‑4 — Heat release and smoke testing for automotive interior materials

ASTM E162 — Surface flammability: smoke density and flame spread

ASTM E648 — Flame propagation of carpet materials

UL 94 — Plastic material flammability: vertical and horizontal burning tests

BS 6853:1999 — Railway vehicle material flame spread, smoke density, and toxicity evaluation

BS 476‑6:1989 + A1:2009 — Fire performance test of building materials, Part 6: Small flame spread method

Parameters

| Parameter | Specification |

|---|---|

| Dimensions | 950 × 600 × 870 mm |

| Weight | 105.5 kg |

| Heating Devices | 2 × 1000 W quartz heaters providing thermal radiation |

| Burner Type | T-shaped tubular burner |

| Sample Holders | 3 types, stainless steel wrapped |

| Thermocouples | Continuously measure temperature difference between chimney and room |

| Power Output Control | Automatic adjustment according to test timeline |

| Data Acquisition | Computer-based, report generation |

Features

Durable stainless steel frame: Ensures structural stability and long-term reliability.

Silicate combustion chamber: Provides uniform and controlled testing environment.

Multiple sample holders: Accommodate different test configurations securely.

Quartz heaters: Deliver consistent thermal radiation to samples.

T-shaped burner: Provides precise direct flame for small flame spread tests.

Continuous temperature monitoring: Thermocouples record chimney versus room temperature.

Automatic power control: Heater output adjusts automatically according to test timeline.

Integrated data acquisition: Computer automatically processes data and generates test reports.

Accessories

Quartz radiation heaters (2 × 1000 W)

T-shaped tubular burner

Stainless steel sample holders (3 types)

Silicate combustion chamber

Thermocouples and mounting accessories

Integrated computer and printer with data acquisition system

Test Procedures

Install the sample in the combustion chamber using the appropriate sample holder.

Connect the G112 test gas supply.

Start the quartz heaters and T-shaped burner, providing thermal radiation and flame exposure.

Adjust heater power automatically according to the test schedule:

First 2 min 45 s: initial burner exposure at 530 J/s

At 2:45 min: increase total heater power to 1800 W

At 5 min: reduce power to 1500 W and maintain until test end

Record flame propagation, temperature, and FSI using the thermocouple and data acquisition system.

Total test duration is 20 minutes. Upon completion, safely remove the sample and review results.

FAQ

1. What is this product?

It is a Flame Spread Index Tester designed to measure the small flame propagation and fire performance of wall, ceiling, and insulation materials.

2. What is it used for?

You can use it to evaluate material flame spread index (FSI), ensure compliance with building and railway fire safety standards, and support material development.

3. How does it work?

The sample is exposed to controlled thermal radiation and ignited with a T-shaped burner. Thermocouples and data acquisition record temperature differences and flame spread, from which the flame spread index is calculated.

4. Why is it important?

This tester allows you to reliably assess fire performance of construction and insulation materials, ensuring safety and compliance with international fire standards.

5. Which industries is it suitable for?

Building materials, railway vehicle materials, plastic materials, interior decorations, aerospace interiors, fire safety research, and quality control laboratories.

Leave Message Get Price