NEXGEN Aviation Fuel Burner

The NEXGEN Aviation Fuel Burner is an FAA-approved, next-generation aircraft fuel combustion testing instrument. It builds upon the operational principles of previous FAA-recognized burners, including Park DPL 3400. Lennox Model OB-32. and Carlin Model 200 CRD, which are now discontinued. You can use the NexGen Burner to precisely control fuel and airflow parameters during tests while maintaining compatibility with future FAA upgrades. This burner supports a wide range of aviation fuel combustion tests, ensuring accurate, reproducible evaluation of flame spread, heat release, and fire resistance for aircraft materials.

Application

The NexGen Aviation Fuel Burner is suitable for a variety of aerospace testing applications:

Aircraft Cabin Materials: Evaluate seat cushions, insulation, and cabin panels for flame spread and smoke toxicity in compliance with FAR 25.853. FAR 25.855. and FAR 25.867.

Cargo Compartment Materials: Conduct burn-through resistance testing on cargo liners and panels.

Soft and Hard Tubing Assemblies: Test fuel, hydraulic, and electrical conduit assemblies under controlled flame conditions.

Electrical Components and Engine Assemblies: Assess fire resistance of electric motor housings, connectors, and wiring.

Material R&D and Certification: Support aerospace material certification for FAA and international standards.

Typical test materials include seat foams, insulation panels, composite laminates, electrical housings, tubing, and other interior aircraft components.

Standards

The NexGen Burner supports compliance with multiple international aviation and safety standards:

BSS 7303 – Aerospace composite material combustion and heat release testing.

BSS 7323 – Aerospace material smoke generation and toxicity evaluation.

BSS 7387 – Aerospace material flame spread and combustion behavior testing.

AITM 2.0056 – Cone calorimeter heat release rate measurement.

AITM 2.0010 – Smoke generation measurement for aerospace materials.

AITM 2.0009 – Flame spread performance measurement for aerospace materials.

FAR Part 25 Appendix F Part II – Cabin material combustion, flame spread, and smoke toxicity testing.

FAR Part 25 Appendix F Part III – Cabin material flame spread and smoke performance measurement.

FAR Part 25 Appendix F Part VII – Cabin material heat release and combustion performance testing.

ISO 2685:1998 – Fire resistance testing methods for aerospace materials.

Domestic Standards: MH/T 6086. HB 7263. MH/T 6041. GB/T 25352. HB 7044 – Various fuel combustion and burn-through testing methods.

Parameters

| Parameter Category | Details |

|---|---|

| Dimensions | 20 mm (W) × 1150 mm (L) × 250 mm (D) |

| Weight | 10 kg |

| Flame Temperature | ≥ 2000 ± 50 ℉ |

| Flame Heat Flux | ≥ 10.6 W/cm² |

| Power Supply | 220 V, 5 A |

| Fuel Requirement | Aviation Grade 2 Fuel |

| Gas Requirement | Compressed air ≥ 120 psi |

Features

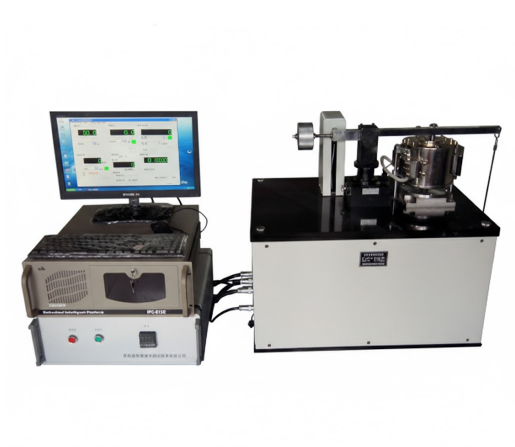

Burner cone made from corrosion-resistant, high-temperature alloy.

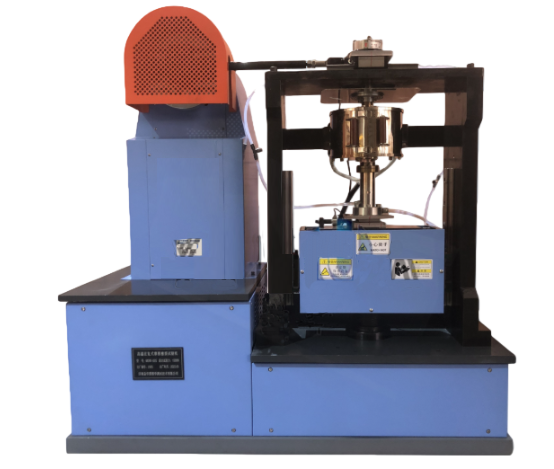

Complete assembly includes diffuser, fuel nozzle, igniter, fuel rail, mounting bracket, ventilation duct, housing, silencer, and acoustic barrier.

Equipped with fuel pressure gauge, fuel solenoid valve, fuel temperature sensor, air regulator, and air temperature sensor.

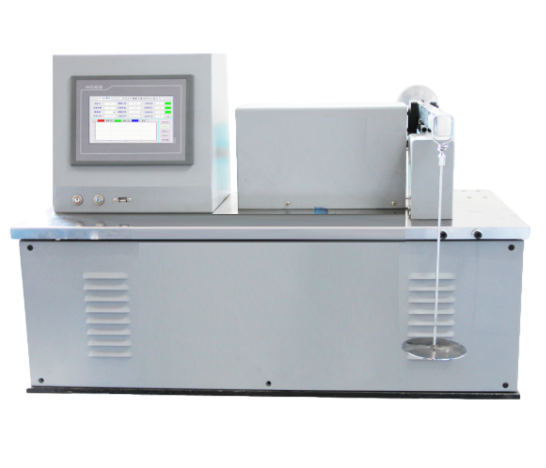

Temperature-controlled fuel and air baths (≥ 2 × 0.14 m³) maintain stable testing conditions.

Adjustable fuel nozzle and air pressure allow compliance with various test standards.

Insulation blankets cover fuel lines and burner body for safety and heat containment.

Capable of providing flame temperatures of at least 2000 ± 50 ℉.

Capable of providing flame heat flux of at least 10.6 W/cm².

Accessories

Fuel and air temperature control bath

Fuel solenoid valve and pressure gauge

Igniter assembly

Adjustable fuel nozzle

Insulation blankets and acoustic silencer

Mounting brackets and ventilation duct

Air regulator and temperature sensors

Test Procedures

Ensure installation space allows safe operation and access.

Connect the burner to 220 V, 5 A power supply.

Connect aviation-grade fuel and confirm compressed air supply ≥ 120 psi.

Mount the burner securely with insulation blankets applied to fuel lines and housing.

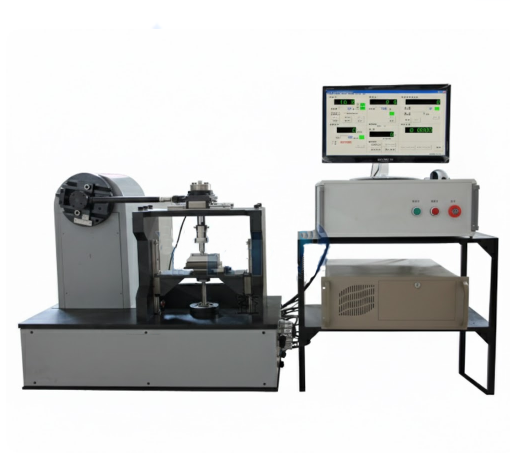

Adjust fuel nozzle and air pressure according to the selected test standard.

Activate the igniter to start the flame.

Monitor fuel flow, air pressure, flame temperature, and heat flux using gauges and sensors.

Conduct burn-through or flame spread tests on the sample material.

Record all test data for compliance reporting.

Shut off fuel and air supply, and allow the burner to cool before disassembly.

FAQ

1. What is this product?

The NEXGEN Aviation Fuel Burner is an FAA-approved instrument for controlled aviation fuel combustion testing, designed to evaluate flame spread, heat release, and burn-through of aircraft materials.

2. What is it used for?

It is used to test aircraft interior materials, fuel and hydraulic assemblies, and electrical components to ensure compliance with FAA, ISO, and domestic aerospace fire safety standards.

3. How does it work?

The burner generates a high-temperature flame using aviation fuel and controlled airflow. Sensors monitor fuel pressure, air pressure, temperature, and heat flux to produce accurate combustion data.

4. Why is it important?

This burner ensures aircraft materials meet strict fire safety requirements, helping prevent cabin fire hazards and supporting FAA and international certification.

5. Which industries is it suitable for?

It is suitable for aerospace, aircraft interior manufacturing, material testing laboratories, and R&D facilities evaluating fire performance of aviation materials.

Leave Message Get Price