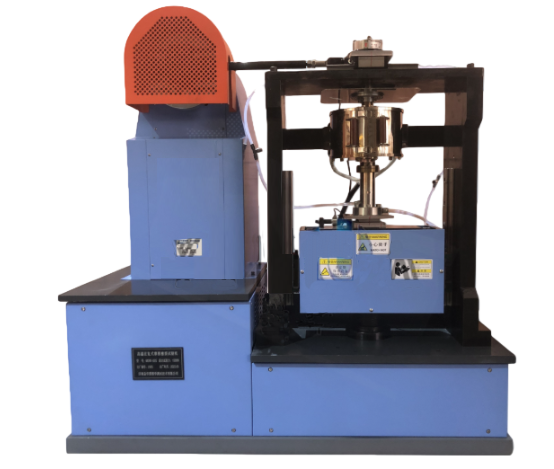

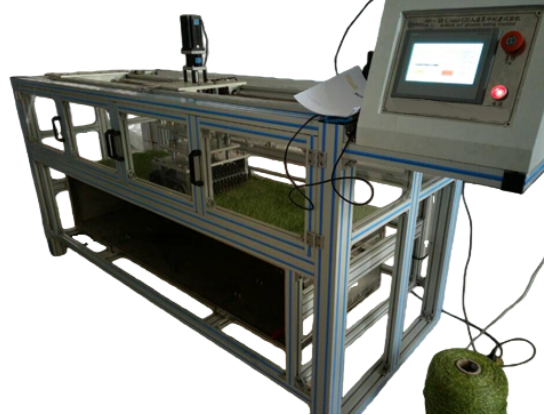

Aviation Propulsion Fuel Test System

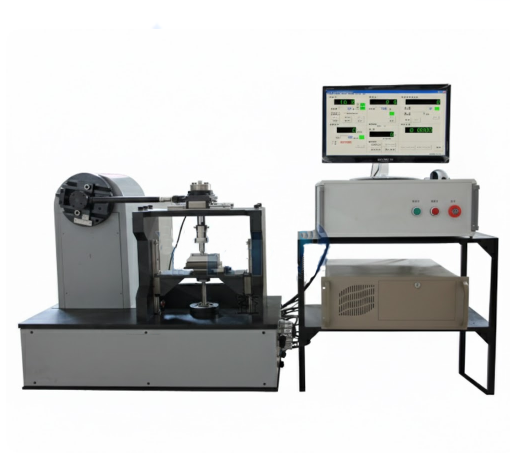

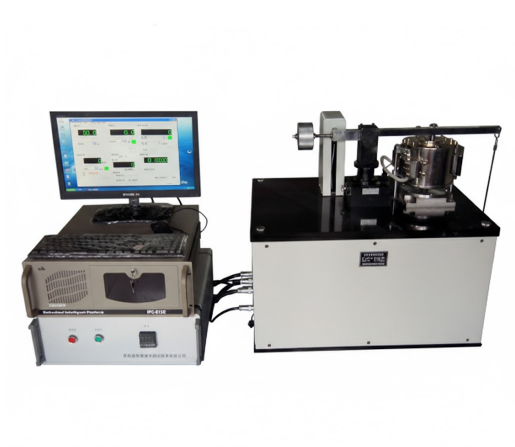

The Aviation Propulsion Fuel Test System is a precision testing platform designed for evaluating fuel combustion and performance in aircraft propulsion components. You can use it to conduct automated fuel burn tests on aerospace power units, measuring fuel flow, pressure, temperature, and combustion characteristics under controlled conditions. The system incorporates the FAA-approved NexGen Aviation Fuel Burner, compatible with previous generation burners such as Park DPL 3400. Lennox Model OB-32. and Carlin Model 200 CRD, while providing enhanced control and modularity for future upgrades.

Application

The Aviation Propulsion Fuel Test System is suitable for a wide range of aerospace testing applications:

Aircraft Propulsion Components: Automated fuel combustion testing for turbines, pumps, and engine assemblies.

Fuel System Evaluation: Measure fuel system performance, burn characteristics, and low-temperature operability.

Component Fire Safety: Conduct controlled burn tests on aircraft fuel lines, fuel pumps, and connected systems.

R&D and Certification Testing: Support FAA, ISO, and SAE compliance testing of fuel systems and propulsion components.

Integration Testing: Test aircraft modules and subassemblies under simulated operational and thermal load conditions.

Typical test products include aircraft turbine fuel pumps, valves, fuel lines, engine components, and other fuel system assemblies.

Standards

The system supports compliance with international and domestic standards for aviation fuel system testing:

FIRE TEST HANDBOOK: Chapter 12 – Material and component fire testing methods.

ISO 8217 – Aviation turbine fuel specifications.

ISO 11170 – Aircraft fuel pump performance testing.

ASTM D1655 – Aviation turbine fuel standards.

ASTM D3241 – Fuel combustion performance and low-temperature testing.

SAE AS22771 – Aviation engine fuel system component testing.

SAE AS1241 – Fuel pump performance and durability tests.

FAR Part 33 – Aircraft engine airworthiness, including fuel system design and testing.

FAR Part 23 / Part 25 Appendix F – Fire resistance and performance requirements for fuel systems in transport and general aviation.

DEF STAN 91-091 – UK Defense fuel system performance testing.

EUROCAE ED-79 / ED-79A – Aircraft engine fuel system certification and testing.

BSS Series (e.g., BSS 7220) – Fuel system material flammability and compatibility evaluation.

Parameters

| Parameter Category | Details |

|---|---|

| Dimensions | 1500 mm (W) × 1800 mm (H) × 900 mm (D) |

| Weight | 150 kg |

| Fuel Requirement | Aviation kerosene |

| Compressed Air Requirement | ≥ 120 PSI |

| Power Supply | 220 V, 10 A |

| Operating Temperature | 10°C – 35°C |

| Sample Mounting | Horizontal and vertical installation supported |

Features

Burner cone made from corrosion-resistant, high-temperature alloy.

NexGen Aviation Fuel Burner includes diffuser, fuel nozzle, igniter, fuel rail, mounting bracket, ventilation duct, housing, silencer, and acoustic barrier.

Equipped with fuel pressure gauge, fuel solenoid valve, fuel temperature sensor, air regulator, and air temperature sensor.

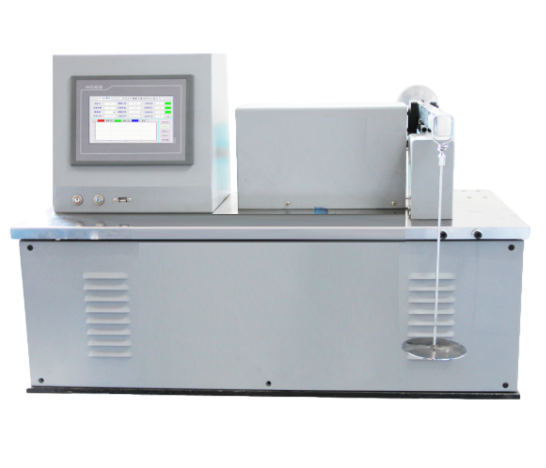

Fuel and air temperature control baths (≥ 2 × 0.14 m³) maintain stable combustion conditions.

Adjustable fuel nozzle and air pressure allow compliance with multiple test standards.

Insulation blankets cover fuel lines and burner body for safety and heat containment.

Supports modular NexGen burner system units for flexibility.

Heavy-duty steel frame supports horizontal and vertical sample installation.

Calibration employs seven 1.6 mm diameter, ceramic-coated, metal-sheathed, grounded K-type thermocouples (AWG 30. 0.0507 mm² cross-section, 361 Ω/km), mounted on an angle-iron thermocouple comb.

Heat flux sensors with cooling system, mounted on fixed supports for accurate measurement.

Accessories

NexGen Aviation Fuel Burner with full assembly

Fuel and air temperature control baths

Fuel solenoid valve and pressure gauge

Igniter assembly

Adjustable fuel nozzle

Insulation blankets and acoustic silencer

Heavy-duty steel mounting frame

Thermocouple comb for calibration

Heat flux sensors with cooling system

Test Procedures

Ensure the installation area is clear and safe.

Connect the system to a 220 V, 10 A power supply.

Supply aviation kerosene fuel and compressed air ≥ 120 PSI.

Mount the test sample securely on the horizontal or vertical frame.

Apply insulation blankets to fuel lines and burner housing.

Adjust fuel nozzle and air pressure according to the selected test standard.

Activate the igniter and NexGen fuel burner.

Monitor fuel flow, air pressure, flame temperature, and heat flux using sensors.

Conduct automated combustion tests on propulsion components.

Record all data for compliance reporting and analysis.

Shut off fuel and air supply and allow the system to cool before sample removal.

Maintenance Information

Inspect the burner cone, fuel nozzle, and igniter for corrosion or wear before each test.

Check fuel and air lines for blockages or leaks.

Periodically calibrate thermocouples and heat flux sensors.

Clean insulation blankets and acoustic components as needed.

Replace any worn or damaged safety components immediately to maintain operational safety.

FAQ

1. What is this product?

The Aviation Propulsion Fuel Test System is a laboratory platform designed for automated fuel combustion testing of aircraft propulsion components.

2. What is it used for?

It evaluates the burn characteristics, heat release, and performance of aircraft fuel systems and engine components to ensure compliance with FAA and international standards.

3. How does it work?

The system uses the NexGen Aviation Fuel Burner to deliver controlled flame and heat while measuring fuel flow, air pressure, temperature, and heat flux on the sample under test.

4. Why is it important?

Accurate fuel combustion testing ensures safe operation of aircraft propulsion components, supports certification, and prevents potential fire hazards.

5. Which industries is it suitable for?

It is suitable for aerospace, aircraft engine manufacturing, fuel system R&D, and aviation material testing laboratories.

Leave Message Get Price