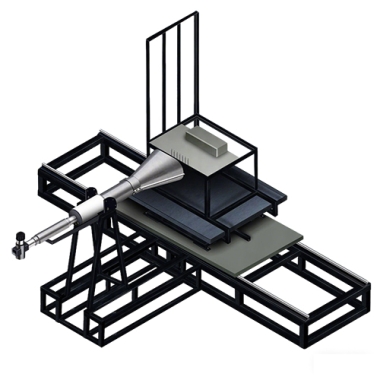

Touch Haptics Test System

The Touch Haptics Test System is a precision laboratory instrument designed to evaluate the tactile perception and haptic quality of automotive interior materials. The system measures key parameters such as indentation force, rebound force, sliding friction, stick-slip behavior, and surface roughness under controlled conditions, providing objective data for material selection, design optimization, and quality control. This ensures user comfort, perceived luxury, and consistent tactile experience in vehicle interiors.

Application

(1) Automotive seat surfaces: leather, fabric, synthetic leather, and composite materials.

(2) Instrument panels, center consoles, and decorative trims: soft-touch plastics, coatings, laminates.

(3) Door panels, armrests, glove compartments: tactile evaluation of touch surfaces.

(4) Steering wheels, gear knobs, cup holders: high-frequency touch surfaces.

(5) Surface treatment and coating optimization: microtexture, friction tuning, coating selection.

(6) Material development and quality control: batch testing, formula improvement.

(7) User experience and ergonomics research: quantitative evaluation of tactile comfort and perceived quality.

Standards

(1) Domestic automotive interior tactile evaluation standards.

(2) OEM internal haptic quality standards (BMW, VW, Ford, etc.).

(3) ISO surface roughness and friction standards: ISO 4287, ISO 4288.

(4) VDA tactile evaluation methods.

(5) ASTM E2530 – Haptic evaluation method.

Parameters

| Parameter | Range / Specification | Description |

|---|---|---|

| Micro Surface Roughness | Ra, Rq, Rz | Nanometer-level accuracy |

| Macro Surface Roughness | Measure material texture / waviness | ±1 μm |

| Indentation Force | 0–50 N | Simulates fingertip pressure |

| Rebound Force | 0–50 N | Measures material recovery |

| Sliding Friction Force | 0–10 N | Static and dynamic friction |

| Stick-Slip Pulse Frequency | 0–150 Hz | Friction discontinuity and micro-slip |

| Temperature Simulation | 0–50 ℃ | Simulates finger contact temperature |

| Sensor Sampling Frequency | ≥1 kHz | Real-time data acquisition |

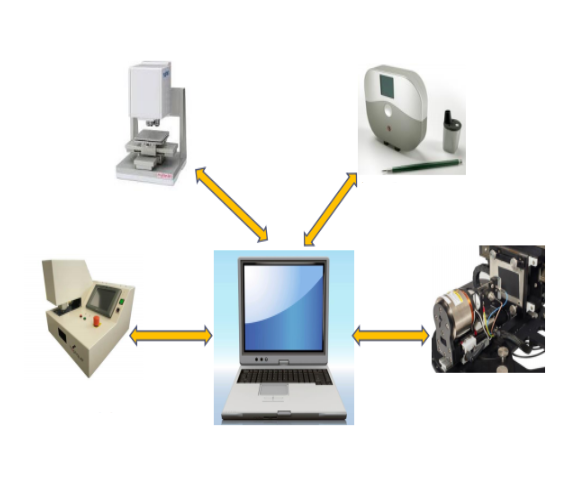

| Control | PLC / PC | Programmable, automatic curves and reports |

| Machine Dimensions | 600 × 400 × 500 mm | Desktop lab design |

| Test Head Type | Artificial finger or custom probe | Simulates real fingertip touch |

Features

(1) Multi-parameter measurement of roughness, indentation, rebound, friction, and stick-slip.

(2) High-precision force, displacement, and vibration sensors.

(3) Environmental simulation: adjustable temperature to replicate fingertip touch.

(4) Intelligent analysis: automatic generation of curves and haptic scores.

(5) High repeatability with standardized fixtures and control system.

(6) User-friendly PC/PLC operation with automatic data recording.

Test Procedures

(1) Fix the material sample in the test fixture, ensuring a flat and stable surface.

(2) Install the test head and set initial contact pressure.

(3) Adjust temperature and testing parameters: indentation, sliding speed, friction stroke.

(4) Start the test program and monitor real-time data for force, displacement, friction, and pulse frequency.

(5) After testing, save data and generate a tactile perception report.

(6) Use protective enclosure if necessary for operator safety.

FAQ

1.What is this product?

It is a laboratory system for evaluating tactile perception and haptic quality of automotive interior materials.

2.What is this product used for?

You use it to measure indentation force, rebound, sliding friction, stick-slip behavior, and surface roughness, providing objective data for material selection and quality control.

3.What is the working principle?

The system applies controlled indentation and sliding motion to samples, measuring force, displacement, friction, and vibration to simulate human touch and haptic perception.

4.Why is this product important?

It ensures automotive interior materials meet user comfort, tactile quality, and perceived luxury standards, supporting design optimization and quality assurance.

5.What industries is this product suitable for?

Automotive interior design, material development, quality control laboratories, and OEM tactile testing departments.

Leave Message Get Price