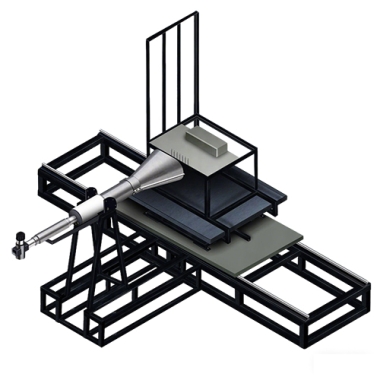

Stick-Slip – Tribological Test Stand (G-SSP)

The Stick-Slip Tribological Test Stand is a laboratory testing system used to evaluate friction-induced stick-slip behavior and squeak noise risk between material pairs under controlled load and motion conditions.

You can use this equipment to measure static friction force, dynamic friction force, coefficient of friction, maximum friction acceleration, and vibration frequency, providing quantitative data for tribological and NVH evaluation.

Application

You can use this test stand to predict friction noise and stick-slip behavior of automotive interior and exterior materials during real use conditions.

It is suitable for the following products and components:

(1) Automotive seat components, instrument panels, door trims, carpets, and interior trim parts

(2) Plastic–plastic, plastic–metal, metal–metal, and composite material friction pairs

(3) Brake pedals, handbrake handles, gear selectors, and tactile control components

(4) Materials with surface treatments, coatings, or layered structures

(5) Material compatibility evaluation to prevent squeak and rattle issues

(6) Tribological performance comparison during material selection and design validation

Standards

(1) VDA 230-206 – Test Method for Evaluation of Friction Noise

(2) BMW PR315 – Friction Noise Evaluation Specification

(3) BMW TL 9169300 – Technical Specification for Friction Properties

(4) VW / Audi / Porsche TL 52064, PV3981 – Friction Noise Testing Standards

(5) Ford L400 – Friction Noise Test Specification

(6) TPJLR-00-230 – Jaguar Land Rover Friction Noise and Tribology Standard

Parameters

| Item | Specification |

|---|---|

| Test Specimen Size | Customized according to customer requirement |

| Normal Load Range | 0–500 N, adjustable |

| Test Stroke | 0–50 mm, adjustable |

| Vibration Frequency | 0–200 Hz, adjustable |

| Static Friction Force Resolution | 0.01 N |

| Dynamic Friction Force Resolution | 0.01 N |

| Maximum Friction Acceleration Resolution | 0.01 m/s² |

| Coefficient of Friction Range | 0–2.0 |

| COF Accuracy | ±0.01 |

| Data Acquisition | Real-time display with curve output |

| Power Supply | 220 V / 50 Hz or 110 V / 60 Hz |

Features

(1) High-precision force and acceleration sensors ensure reliable friction and vibration data.

(2) Supports both static and dynamic friction testing under controlled conditions.

(3) Adjustable load, stroke, and vibration frequency to meet different OEM standards.

(4) Suitable for various material combinations including plastics, metals, and composites.

(5) Real-time data acquisition with force, COF, acceleration, and vibration curves.

(6) Stable mechanical structure with vibration-resistant design for repeatable results.

Accessories

(1) Adjustable specimen clamping fixtures

(2) High-precision force sensor

(3) High-sensitivity acceleration sensor

(4) Test specimens supplied by customer

(5) Control and data acquisition system (PC or PLC based)

(6) Safety enclosure

(7) Standard load weights

Test Procedures

(1) Clean and prepare the test specimens according to the applicable standard.

(2) Mount the specimens securely in the clamping fixtures.

(3) Set the required normal load, stroke, vibration frequency, and test duration.

(4) Configure data acquisition parameters and sampling rate.

(5) Start the test and apply friction motion under controlled conditions.

(6) Record friction force, coefficient of friction, acceleration, and vibration signals.

(7) Stop the test after completion and save all measurement data.

Maintenance Information

(1) Regularly inspect fixtures, sensors, and mechanical moving parts.

(2) Calibrate force and acceleration sensors at defined intervals.

(3) Keep sliding surfaces clean to prevent contamination-induced measurement errors.

(4) Check electrical connections and data acquisition stability.

(5) Store the equipment in a clean and controlled laboratory environment.

FAQ

1. What is this product?

It is a tribological test stand for evaluating stick-slip behavior and friction noise risk between materials.

2. What is this product used for?

It is used to measure static and dynamic friction, coefficient of friction, vibration, and squeak noise tendency.

3. Why is this product important?

It helps predict friction-induced noise issues and supports material compatibility and design decisions.

4. What industries is this product suitable for?

Automotive manufacturing, material development, OEM laboratories, and third-party testing institutions.

5. What types of this product are available?

Standard laboratory configurations with customizable load range, stroke, and vibration frequency options.

Leave Message Get Price