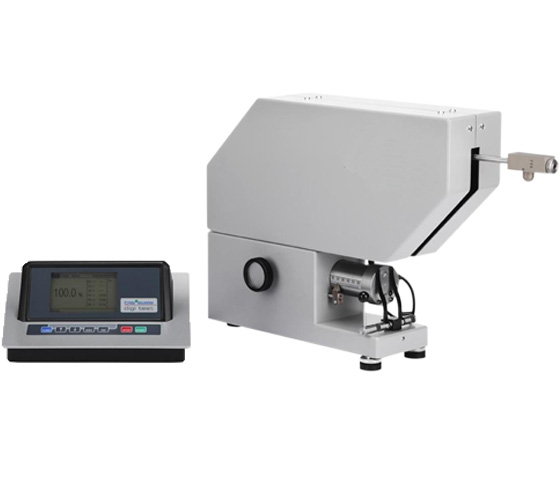

Automatic Rebound Elasticity Tester

The Automatic Rebound Elasticity Tester is designed for evaluating the elastic performance of soft elastic materials, including rubber, elastomers, and soft foams. It measures dynamic rebound to determine changes in material elasticity under prolonged or repeated loading. The fully automatic design minimizes operator training and human error. The electronic control system operates independently of the pendulum mechanism, reducing failure rates and simplifying sample calibration and maintenance. An optional sample heater can simulate high-temperature effects up to 100℃. The system also features intelligent sample detection to prevent operation errors and equipment damage.

Application

(1) Rubber products: natural rubber, synthetic rubber elasticity testing.

(2) Elastomer materials: silicone, TPR, TPU, and similar materials performance evaluation.

(3) Soft foam materials: PU foam, EVA, rubber foams, and rebound performance testing.

(4) Sealing and gasket materials: rubber gaskets and sealing strips durability and elasticity assessment.

(5) Footwear and sports materials: shoe soles, protective gear cushioning performance analysis.

(6) Material R&D and quality control: formulation optimization, batch consistency verification, and durability assessment.

(7) Reference industries: automotive parts, footwear manufacturing, elastomer R&D laboratories.

Standards

(1) GB/T 1681 – Rubber rebound resilience test method.

(2) DIN 53512 – Rubber resilience determination.

(3) DIN 53573 – Rubber and elastomer resilience test.

(4) ISO 4662 – Rubber resilience measurement.

(5) ASTM D 1054 – Rubber rebound resilience testing.

Note: Standards apply to rubber and soft foam with Shore hardness 30–85 or IRHD N range.

Parameters

| Parameter | Specification | Description |

|---|---|---|

| Test Range | Shore 30–85 / IRHD N | Suitable for elastomers and soft foams |

| Measurement Method | Pendulum Rebound | Dynamic elasticity measurement, median value calculation |

| Control Mode | Serial Interface / Fully Automatic | Detects sample installation, prevents errors |

| Temperature Control | Optional heater, up to 100℃ | Simulates high-temperature effect on elasticity |

| Pendulum Weight | Standard | Set according to test standards |

| Instrument Weight | 37 kg | Compact tabletop design |

| Instrument Dimensions | 470 × 110 × 350 mm | Laboratory-friendly footprint |

Features

(1) Fully automatic operation: minimal training required, reduces human error.

(2) Intelligent sample detection: pendulum does not operate if sample is improperly installed.

(3) Dynamic elasticity testing: real-time measurement of material rebound behavior under load.

(4) High-temperature simulation: optional heater evaluates material elasticity under elevated temperatures.

(5) Standard compliance: compatible with GB, DIN, ISO, and ASTM standards.

(6) Low failure rate: electronic control independent of pendulum mechanism, easy maintenance and calibration.

Test Procedures

(1) Prepare samples to standard dimensions and secure them in the test fixture.

(2) Confirm correct installation before starting the instrument to prevent pendulum damage.

(3) Set testing temperature (if simulating high temperature), number of tests, and standard type.

(4) Start the test; the instrument automatically performs pendulum rebound measurement and records data.

(5) Save or export the data report after testing for material R&D or quality control.

(6) Keep the instrument dry and clean; avoid liquids or debris entering the pendulum mechanism.

FAQ

1.What is this product?

It is a laboratory instrument for evaluating the rebound elasticity of soft elastic materials such as rubber, elastomers, and foams.

2.What is this product used for?

To measure dynamic rebound performance and assess elasticity changes under repeated or prolonged loading, including high-temperature simulation.

3.What is the working principle?

A pendulum impacts the sample surface from a fixed height, and the rebound height or time is measured. The rebound rate reflects the material’s elastic performance. Median values are calculated for standardization.

4.Why is this product important?

It provides reliable data for material R&D, batch quality control, formulation optimization, and durability assessment under different conditions.

5.What industries is this product suitable for?

Automotive components, footwear manufacturing, elastomer material R&D laboratories, and quality control labs.

Leave Message Get Price