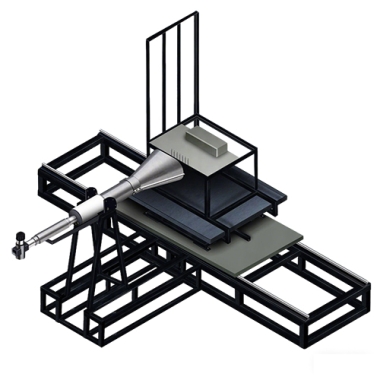

Automatic Hardness and Density Testing Machine

The Automatic Hardness and Density Testing Machine is designed for high-throughput hardness and density measurement of rubber samples. It is mainly used in tire factories, sealing product manufacturers, rubber mixing centers, and rubber raw material laboratories. The system automates the entire testing process—combining robotic sample handling, digital Shore durometers, and high-precision balances—to ensure efficient, accurate, and low-error measurement of both hardness and density.

Application

(1) Soft rubber and natural rubber products: hardness and density testing.

(2) Tire industry: rapid inspection in rubber mixing centers, raw material quality control, batch consistency checks.

(3) Sealing products and rubber parts: performance evaluation and quality control.

(4) Rubber compounding and raw material testing: formula optimization and pre-vulcanization sample assessment.

(5) Laboratory high-throughput testing: suitable for hundreds to thousands of samples per day.

(6) R&D and QC workflow: evaluate hardness and density parameters, optimize production processes, and verify compliance with standards.

Standards

(1) GB/T 531.1-2008: Rubber hardness measurement (Shore A/D).

(2) GB/T 531.2-2008: Rubber hardness measurement (IRHD method).

(3) ISO 7619-1: Rubber and elastomer Shore hardness measurement.

(4) ISO 2758: Rubber density measurement via displacement method.

(5) DIN ISO 7619 / DIN EN ISO 868 / ASTM D 2240 (hardness).

(6) ISO 2781 / DIN EN ISO 1183-1 / ASTM D1817 (density).

Parameters

| Parameter | Specification | Description |

|---|---|---|

| Sample Diameter | 36–42 mm | Customizable per customer requirements |

| Sample Thickness | ≥6 mm | Compliant with Shore A measurement requirements |

| Test Cycle | 100 samples / sleeve | Continuous cycle, multiple sleeves can be loaded alternately |

| Test Capacity | 1200 pcs / 24h | Approximately 2 hours per 100 samples |

| Hardness Test Points | 3-point average (expandable to 5) | Digital Shore A / IRHD |

| Hardness Test Force | ≥1 kg | Holding time adjustable 0–99 s |

| Hardness Test Head | Digital Shore durometer | Shore A or IRHD measurement |

| Density Measurement | Displacement method | High-precision balance, error ≤0.1 mg |

| Control System | PLC + touch screen | Data acquisition and remote maintenance |

| Sample Handling | Pneumatic robotic arm | Automatic transport and positioning |

| Working Temperature | 20–45 ℃ | Samples cooled to ideal 20 ℃ |

| Machine Design | 7×24h continuous operation | Durable, low-maintenance |

Features

(1) High-throughput automation: robotic sample handling, hardness, and density testing.

(2) Fully automated hardness measurement: Shore durometer with 3–5 point average.

(3) Precision density measurement: displacement method with high-precision balance and vibration protection.

(4) Intelligent sample sensing: detects improper placement to prevent instrument damage.

(5) Modular design: separate in/out feed, hardness and density modules, and control system for easy maintenance.

(6) High reliability: pneumatic robotic arm minimizes manual operation.

(7) Traceable data: hardness and density results can be filtered and traced.

(8) Expandable functions: adjustable test force and holding time for different rubber types and custom requirements.

Accessories

| Accessory / Consumable | Specification | Function |

|---|---|---|

| Sample Sleeve | 100 pcs / sleeve | Sample loading and automatic flow |

| Hardness Test Head | Digital Shore durometer | Shore A or IRHD measurement |

| Turntable Sample Slot | Standardized design | Sample positioning and handling |

| Balance | Precision 0.1 mg | Density measurement via displacement method |

| Testing Liquid | Anti-bubble water | Used in displacement density testing |

| Robotic Arm | Pneumatic | Automatic sample transport to testing modules |

| Control Software | PLC + touch screen | Data acquisition, sample flow, and remote maintenance |

| Data Interface | USB / Ethernet | Data output for database or MES integration |

Test Principle

(1) Hardness Testing: Samples are placed into turntable slots; the Shore durometer automatically loads and measures 3–5 points. Data is recorded in real time.

(2) Density Testing: After hardness testing, the robotic arm transfers samples to the balance, measuring density via the displacement method.

(3) Data Processing: Hardness and density results are automatically recorded, filtered, and traceable. Data can be exported to customer databases or MES systems.

Operation Instructions

(1) Load samples sequentially into sleeves and cool to 20–45 ℃.

(2) Power on the instrument and control system; check robotic arm and turntable status.

(3) Set test parameters: hardness points, holding time, cycle quantity.

(4) Start automatic testing; the system conducts hardness and density measurements.

(5) After completion, review displayed results and export data.

(6) Regularly maintain robotic arm, balance, and hardness test head to ensure long-term stable operation.

FAQ

1.What is this product?

A fully automated system for high-throughput hardness and density measurement of rubber samples.

2.What is this product used for?

To assess the elasticity and density of soft rubber and natural rubber products for R&D, QC, and production monitoring.

3.What is the working principle?

Samples are automatically measured by a digital Shore durometer for hardness, then transferred for density measurement via the displacement method.

4.Why is this product important?

It enables high-throughput, low-error testing of rubber samples, ensuring product consistency and compliance with standards.

5.What industries is this product suitable for?

Tire manufacturers, rubber sealing products, rubber raw material labs, and rubber compounding centers.

Leave Message Get Price