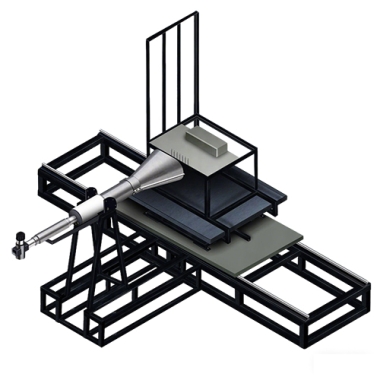

Laser Compression Deformation Tester

The Laser Compression Deformation Tester for sealing strips is designed for automotive sealing strips to precisely measure compression deformation and residual deformation. Using non-contact laser scanning technology, it captures linear compression curves with high accuracy and repeatability. The system evaluates elastic sealing strips throughout compression and release, generating quantitative data for quality control and R&D analysis.

Application

(1) Automotive sealing strip testing: door, window, trunk, and hood seals compression and permanent deformation evaluation.

(2) Automotive elastomer components: seals, vibration dampers, and elastic parts long-term compression performance testing.

(3) R&D and quality control: new material development, material selection, and batch consistency verification.

(4) Automotive supply chain: supplier quality inspection to ensure compliance.

(5) Environmental simulation: combined with temperature and humidity testing for deformation behavior under various conditions.

(6) Industrial rubber products: applicable to other elastic rubber profiles beyond automotive seals.

Standards

(1) GB/T 7759-2008: Determination of compression set of rubber and rubber products.

(2) GB/T 21282-2007: Compression performance testing for automotive rubber seals.

(3) QC/T 709-2007: Automotive rubber seal compression performance test specification.

(4) VW PV 3363: Determination of permanent deformation of automotive sealing strips.

(5) SMTC 3 C00003-2010: Sealing strip compression performance test.

Parameters

| Parameter | Specification | Description |

|---|---|---|

| Base Plate Size | 750 × 530 mm² | Width × Depth |

| Machine Height | ~500 mm | Including laser measurement device |

| Instrument Weight | ~42 kg | Easy installation and handling |

| Laser Measurement Range | 1–60 mm | Non-contact scanning |

| Measurement Accuracy | <6 µm | Precision compression measurement |

| Measurement Resolution | 0.00005–0.1 mm | High-resolution data acquisition |

| Software Platform | Windows 7 or higher | Data recording and processing |

| Data Output | MS Excel / Print | Compression-time curve and residual deformation report |

| Adjustable Measurement Time | Continuous or interval measurement | User-defined sampling time |

Features

(1) Non-contact laser measurement prevents additional compression or sample damage.

(2) Linear compression curve recording captures full compression and unloading process.

(3) High precision (<6 µm) and high resolution (up to 0.00005 mm).

(4) Automated data processing generates compression-time graphs, residual deformation analysis, and standard deviation.

(5) Multi-point measurement supports sequential or preset-time measurements.

(6) User-friendly Windows software with context help, records username, date, and test time.

(7) Compatible with MS Excel 2000 and above for reporting.

(8) Adjustable clamping device fits different sealing strip sizes.

Accessories

| Accessory / Consumable | Specification | Function |

|---|---|---|

| Laser Scanning Micrometer | Model 3 | Non-contact compression measurement |

| Base Plate | 750 × 530 mm² | Sample support and fixation |

| Sample Clamping Device | Adjustable | Fits different sealing strip sizes |

| Electromagnetic Support | Manual positioning | Lateral adjustment of sample |

| Software | Windows control program | Data recording, processing, report generation |

| Data Interface | USB / Network | Export Excel reports or print |

| Flange Magnet & Main Shaft | Pressure plate fixation | Ensures stable compression |

Procedure

(1) Sample preparation: cut sealing strips to standard size and install in clamping device.

(2) Compression loading: apply linear compression with pressure plate.

(3) Laser scanning: continuously record deformation.

(4) Unload measurement: record residual deformation.

(5) Follow-up measurement: optional tracking at preset times.

(6) Data analysis: generate compression-time curves, residual deformation percentages, average and standard deviation.

(7) Report output: Excel and print reports for R&D and QC.

FAQ

1.What is this product?

The Laser Compression Deformation Tester is a precision instrument for measuring compression deformation and residual deformation of automotive sealing strips and elastic rubber profiles using non-contact laser scanning technology.

2.What is this product used for?

It is used to evaluate the compression performance, permanent deformation, and elastic recovery of automotive sealing strips, elastomer parts, and other industrial rubber profiles under loading and environmental conditions.

3.Why is this product important?

Accurate measurement of compression and residual deformation ensures product quality, guides R&D for new materials, prevents performance failures in automotive sealing systems, and maintains supplier quality compliance.

4.What industries is this product suitable for?

Automotive industry (door, window, trunk, and hood seals), rubber manufacturing, elastomer R&D laboratories, quality control laboratories, and industrial rubber product manufacturers.

5.What types of this product are available?

Standard Laser Compression Deformation Tester for automotive seals; optional versions include multi-point measurement, adjustable sample clamps, and integration with environmental chambers for temperature/humidity simulation.

Leave Message Get Price