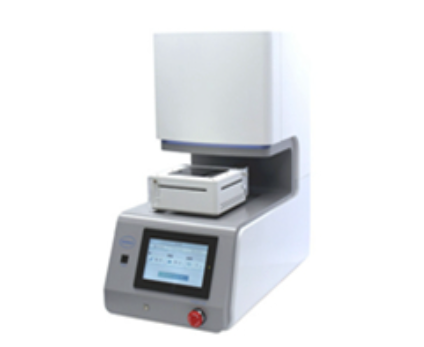

High and low temperature gravel resistant impact tester G-500

The G-500 High and Low Temperature Gravel Resistant Impact Tester is designed to assess the durability of automotive surface coatings under extreme temperature variations and gravel impact conditions. This testing system simulates real-world conditions where coatings are exposed to gravel and stones at high and low temperatures. It is critical for evaluating the resistance of automotive coatings to physical damage and environmental stress, ensuring that coatings can withstand harsh conditions during the service life of vehicles.

Application

The G-500 tester is primarily used for testing the following:

Automotive surface coatings for resistance to gravel impact under temperature extremes

Paints and coatings on vehicles, ensuring they can withstand real-world wear and tear from gravel and stone impacts in both high and low-temperature environments

Evaluation of coating durability during exposure to harsh conditions typical for the automotive industry

Testing for other coatings exposed to environmental stressors in industries like aerospace, military, and industrial manufacturing

Standards

This tester complies with and supports the following international standards:

SAE J400 — Automotive Surface Coating Gravel Impact Resistance Test

ISO 20567-1 — Paints and varnishes — Determination of resistance to stone chipping of coatings — Part 1: Multi-impact test

DIN 55996-1:2001 — Testing of coating materials for resistance to stone chipping — Part 1: Multiple impact test

ASTM D3170-03(2007) — Automotive Paint Gravel Resistance Test

GME 60268-96 — General Automotive Surface Coating Test Methods

GMW14700 — General Motors Coating Test Methods

GM9508P — General Motors Impact Test Standard for Coatings

ISO 20567-1-2005 — Automotive Paint Resistance to Stone Chipping Test

NES M0007 Section 28 — Automotive Coatings Stone Chipping Resistance

DIN EN ISO20567-1-2007 — Automotive Paints: Resistance to Stone Chipping Test

Parameters

| Item | Specification |

|---|---|

| Power Supply | 5.5 kW, AC 220V, Single-phase with neutral wire and protective earth |

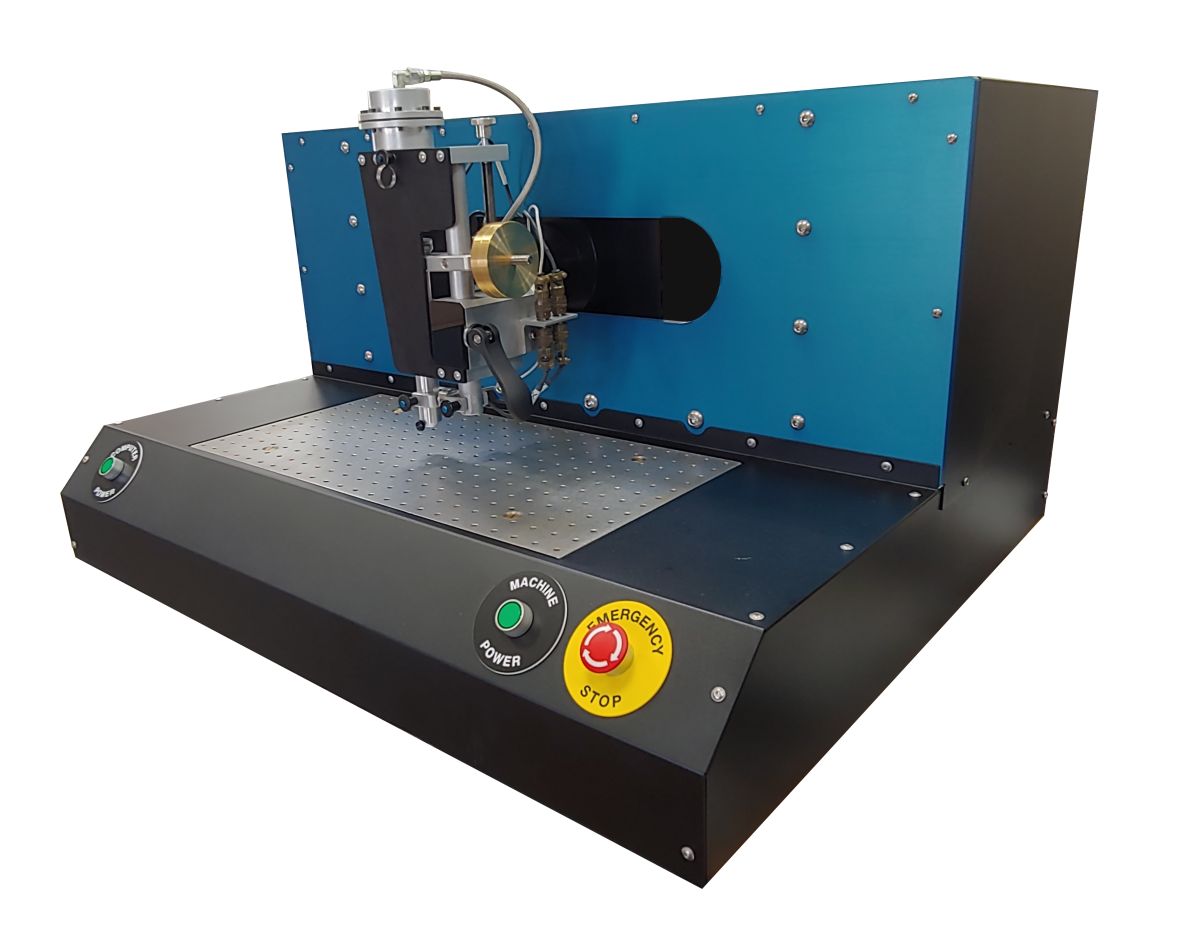

| Impact Media | Crushed stone and steel shot |

| Gun Barrel Inner Diameter | 52.6 mm (SAE J400), 300 mm (VDA) |

| Air Tank Volume | 130 L |

| Sample Placement Angle | SAE: 90°, 45°; VDA: 90°, 54° |

| Custom Plate Fixture | 150*70 mm samples |

| Custom 3D Fixture | Workpieces with a diameter of 650 mm and thickness of 400 mm |

| Temperature Range | High and low temperature range |

| Pressure Range | 0–0.5 MPa (adjustable) |

| Power Consumption | 5.5 kW |

Features

High and low-temperature impact testing for automotive coatings under controlled gravel impact conditions.

Impact media compatibility, including crushed stone and steel shot for different testing requirements.

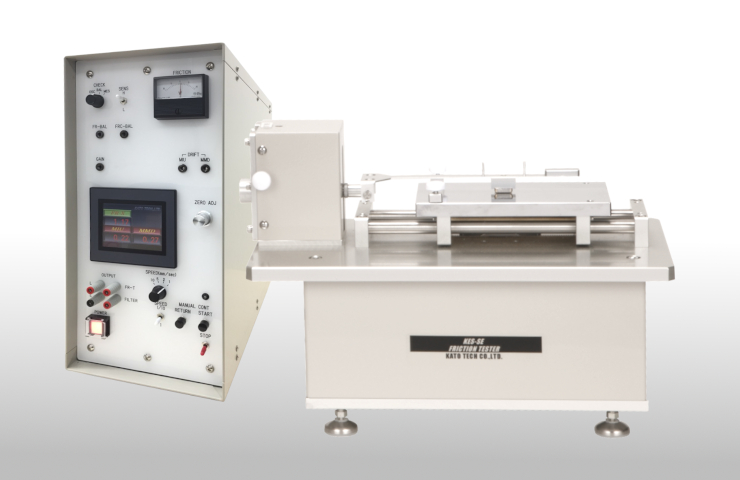

Spray gun configurations for both VDA and SAE standards, allowing for versatile testing.

Efficient power consumption with a 5.5 kW AC power supply.

Customizable fixtures to accommodate different sample sizes and test configurations.

Touch screen control with Chinese/English menu for user-friendly operation.

Compact design for easy integration into testing labs with limited space.

Accessories

Spray gun: One set each of VDA and SAE, with 500g of crushed stone and 500g of steel shot

Custom-made plate fixture: Meets the requirements for 150*70 mm samples

Custom-made 3D fixture: For workpieces with a diameter of 650 mm and thickness of 400 mm

Impact media: Crushed stone and steel shot (500g each)

Touch screen control panel: With adjustable settings for temperature and impact conditions

Test Procedures

Preparation: Ensure that the test sample is securely placed on the specimen holder, and select the appropriate spray gun configuration (VDA or SAE).

Temperature Adjustment: Set the temperature to the desired high or low temperature (within the specified range).

Impact Testing: Activate the spray gun to initiate the gravel impact test. Adjust pressure and sample placement angle according to the required standards.

Monitor: Use the touch screen to monitor the test conditions, including temperature, impact frequency, and media type.

Post-Test Inspection: After the test, inspect the sample for any damage or degradation caused by the gravel impact under extreme temperature conditions.

Data Logging: Record and analyze the results for further evaluation of coating performance.

Maintenance Information

Regular Cleaning: Clean the impact chamber, spray guns, and other components after each use to prevent buildup of test media.

Check Temperature Control: Periodically verify the accuracy of the temperature control system and recalibrate if necessary.

Inspect Components: Ensure that the refrigeration and compressor systems are functioning properly, especially when switching between high and low temperatures.

Replace Consumables: Replace crushed stone and steel shot as needed, and inspect the spray gun for wear.

Service and Calibration: Perform regular servicing and calibration of the system to ensure continued accuracy and reliability.

FAQ

What is this product?

The G-500 High and Low Temperature Gravel Resistant Impact Tester is designed to simulate the impact of gravel on automotive coatings under both high and low temperature conditions.

What is this product used for?

It is used to test the durability and resistance of automotive surface coatings to gravel impact, particularly in extreme temperature environments.

Why is this product important?

It ensures that automotive coatings can withstand real-world wear and tear from gravel and stones, crucial for maintaining vehicle aesthetics and structural integrity under harsh conditions.

What industries is this product suitable for?

This product is primarily used in the automotive industry, especially for testing coatings on vehicles, but can also be used in aerospace, military, and industrial sectors requiring durable surface coatings.

What types of this product are available?

The G-500 tester is available with different configurations for SAE and VDA spray guns, customizable sample fixtures, and varying temperature ranges to suit different testing needs.

Leave Message Get Price