Car seat belt locking performance tester

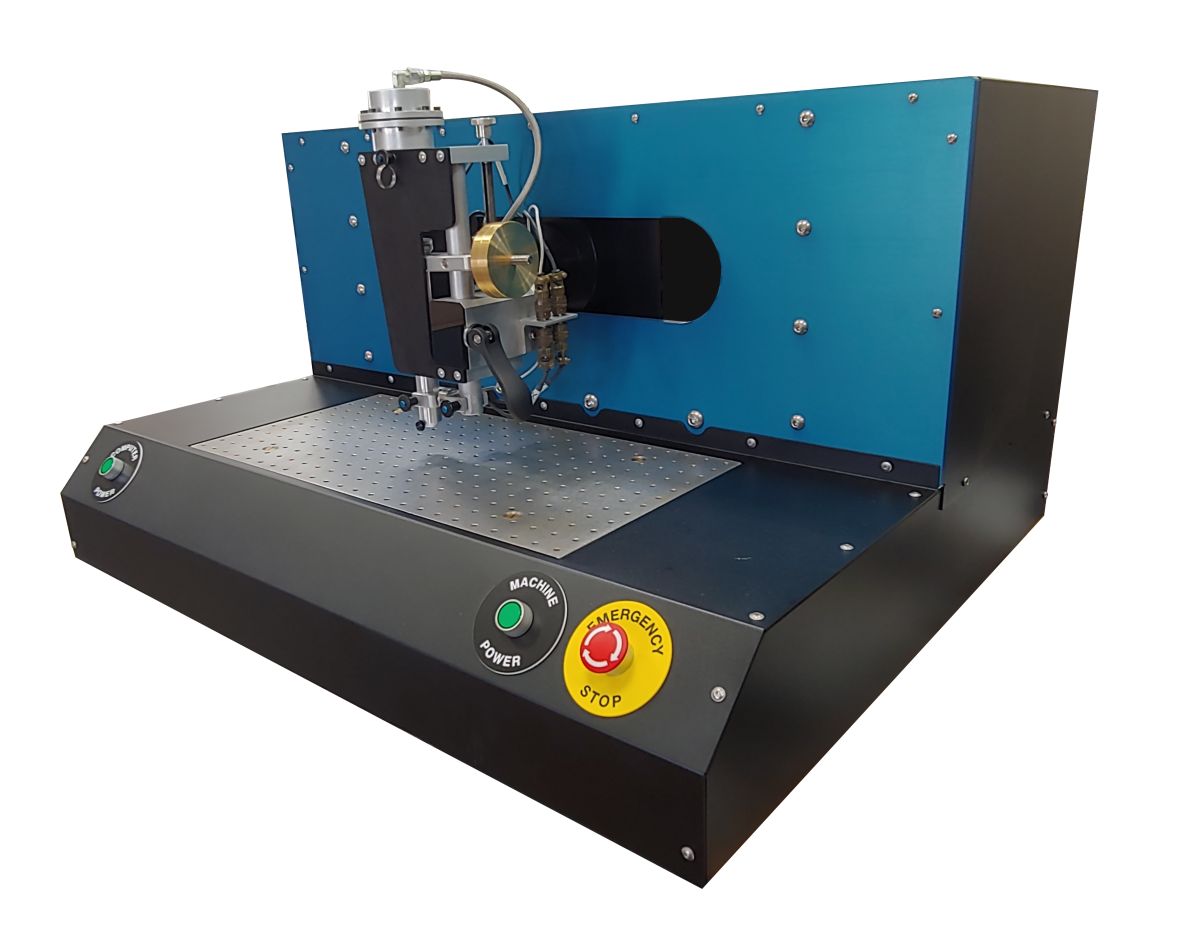

The Car Seat Belt Locking Performance Tester is a professional testing system designed to evaluate the emergency locking function, acceleration response, displacement behavior, and locking distance of automotive seat belt retractors. Built for high reliability and precision, it supports comprehensive safety performance testing required by automotive manufacturers, component suppliers, certification bodies, and research institutions. The system offers automated control, multi-angle configuration, high-accuracy sensors, and fast data acquisition to ensure consistent and repeatable testing results.

Application

(1) Emergency locking performance evaluation of automotive seat belt retractors.

(2) Acceleration response and locking distance measurement under simulated emergency conditions.

(3) Research and development of seat belt systems for vehicle safety.

(4) Quality control and verification testing for seat belt manufacturers.

(5) Compliance testing according to national and international standards.

Standards

1、GB 14166-2013

Seat Belts, Restraint Systems, Child Restraint Systems and ISOFIX Child Restraint Systems for Motor Vehicle Occupants

2、GB 27887-2011

Restraint System for Child Occupants of Motor Vehicles

Features

1、Advanced PLC Control System

Ensures stable test execution, automated operation, and precise data processing.

2、User-Friendly Interface

Equipped with a color touchscreen interface supporting Chinese/English switching, improving usability for global operators.

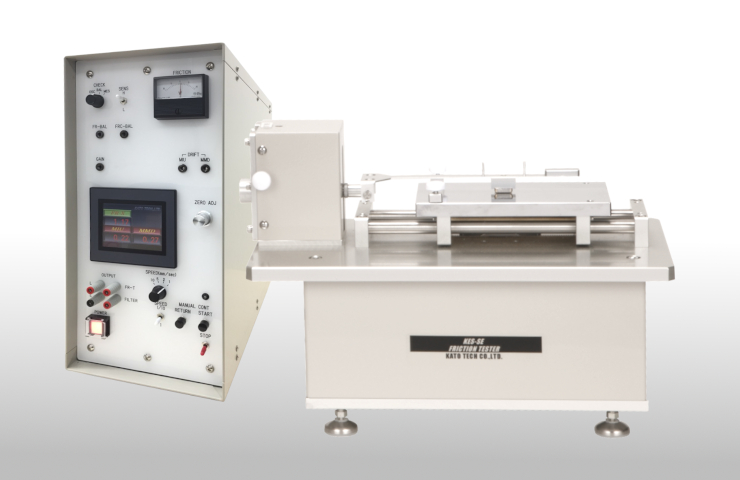

3、Multi-Angle Mounting Design

Supports retractor mounting at 45°, 90°, 135°, and 180° to simulate various vehicle installation conditions.

4、High-Precision Acceleration Simulation

Acceleration range of 0.2–1.5 g with fine adjustment steps ≤ 0.05 g for accurate test condition configuration.

5、High-Accuracy Sensor System

Acceleration accuracy < 0.01 g; locking distance accuracy ≤ 0.01 mm ensures trustworthy measurement results.

6、Fast Emergency Locking Simulation

Achieves 2.94 m/s within 50 ms, replicating real-world emergency braking and impact scenarios.

7、Industrial-Grade Mechanical Structure

Stable, durable, and designed for long-term continuous operation in professional laboratories.

Parameters

| Parameter | Specification |

|---|---|

| Control System | PLC automation + data processing |

| Operation Interface | Color touchscreen (Chinese/English) |

| Emergency Lock Test Speed | 2.94 m/s within 50 ms |

| Mounting Angle Options | 45°, 90°, 135°, 180° |

| Acceleration Adjustment Range | 0.2–1.5 g |

| Acceleration Adjustment Step | ≤ 0.05 g |

| Maximum Sled Displacement | 100 mm |

| Inductive Acceleration Range | ≥ 0.2–2.5 g |

| Acceleration Measurement Accuracy | < 0.01 g |

| Acceleration Repeatability | ≤ ±0.01 g |

| Acceleration Overshoot | < 10% of set value |

| Locking Distance Accuracy | ≤ ±0.01 mm |

Accessories

1、Seat belt retractor mounting fixtures

2、Adjustable installation frame

3、Acceleration calibration module

4、High-precision displacement sensors

5、Data acquisition & analysis software

6、Industrial computer with data storage

7、Protective covers and anti-vibration base

Test Procedures

1、Install the seat belt retractor at the required mounting angle.

2、Set acceleration, movement, and locking parameters via touchscreen.

3、Start the test; the system automatically executes the acceleration and locking procedure.

4、View, store, or export test data in CSV format for reporting and analysis.

Leave Message Get Price