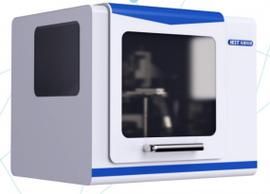

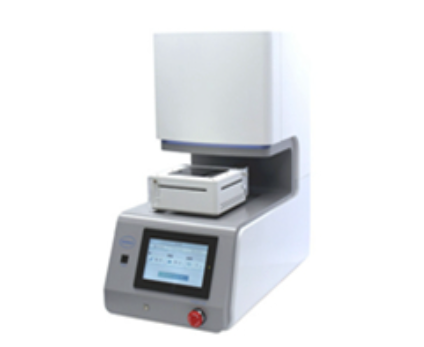

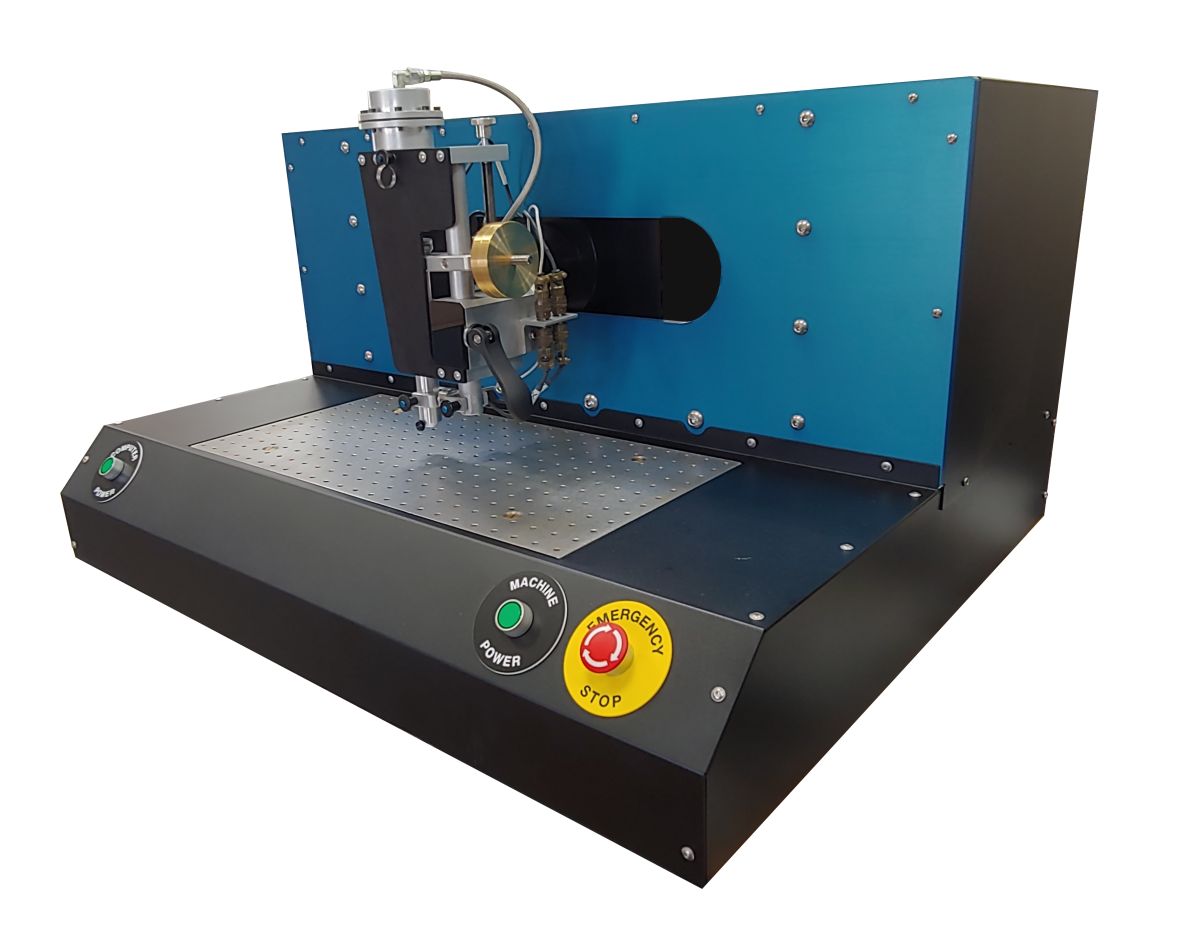

Single particle mechanical properties tester

Standard

- ISO 13314 (Mechanical testing of metals – Instrumented indentation test for hardness and materials parameters)

- ASTM E9 (Standard test methods of compression testing of metallic materials at room temperature)

- GB/T 21838.4 (China’s national standard for metal materials – Hardness and test methods)

- IEC 62660-2 (Secondary lithium-ion cells – Reliability and abuse testing)

Product Advantages

- Nanoscale Precision

- 0.01μm displacement resolution and ±0.1% force accuracy for capturing sub-micron deformation in electrode particles.

- 100N load cell with ultra-low noise floor (0.001N resolution) for fragile material testing.

- Real-Time Morphological Analysis

- Integrated optical microscope: 1,000x magnification with coaxial LED illumination for live particle compression imaging.

- AI-assisted fracture detection: Automatically identifies stress-strain curve inflection points (R² > 0.998 accuracy).

- Multi-Modal Testing

- Control modes: Displacement-controlled (0.1–100μm/s) or force-controlled (0.01–100N) operation.

- Custom protocols: Lithium-ion particle-specific testing (e.g., SEI layer adhesion, delamination resistance).

- Smart Data Ecosystem

- Cloud-connected software: Stores 1M+ data points with spectral analysis tools (FFT, wavelet transforms).

- API integration: Export results to COMSOL/MATLAB for multi-physics simulations.

- Industrial Durability

- Vibration-damped frame: Isolates 200Hz environmental noise for sub-micron stability.

- Self-cleaning indenter: CO₂ laser ablation prevents cross-contamination between tests.

Product Features

- Optical System:

- Microscope: 1,000x magnification, 0.5μm depth of field, 16:9 HD video output.

- LED illumination: Adjustable intensity (0–10,000 lux) with polarizing filter for specular reflection reduction.

- Actuation System:

- Piezoelectric stage: 100mm x 100mm x 50mm travel range, 0.01μm closed-loop resolution.

- Indenter options: Berkovich, Vickers, and flat punch geometries (diamond/sapphire tips).

- Control Panel:

- 10.1" capacitive touchscreen with live stress-strain curves and 3D force mapping.

- Embedded software: Auto-generates reports with Young’s modulus, hardness, and fracture toughness.

- Safety Features:

- Emergency ejection, over-force shutdown, and anti-tip base (4-point leveling).

- Calibration:

- NIST-traceable standards: Tungsten carbide hardness block (1,500 HV) and laser interferometer.

Technical Parameters

| Specification | Details |

|---|---|

| Force Range | 0.01–100N (100N load cell, ±0.1% accuracy) |

| Displacement Resolution | 0.01μm (piezoelectric stage) |

| Loading Rate | 0.1–100μm/s (displacement-controlled) |

| Microscope Resolution | 0.5μm (optical), 10nm (digital zoom) |

| Data Acquisition | 1MHz sampling rate, 16-bit ADC |

| Temperature Stability | 20–25°C (±0.1°C via Peltier control) |

| Power Requirements | 100–240V AC, 50/60Hz, 600W |

| Footprint | 600mm (L) x 500mm (W) x 800mm (H) |

| Weight | 80kg (net) / 100kg (with accessories) |

Accessories Included

- Indenter Kit – Berkovich, Vickers, and flat punch indenters (diamond/sapphire).

- Calibration Set – NIST-traceable hardness block and laser interferometer.

- Particle Handling – Vacuum chuck with anti-static coating, 50mm Petri dishes.

- Software License – Lifetime access to NanoMechanica Pro (cloud-connected with COMSOL/MATLAB API).

- Installation & Training – On-site setup by certified engineers + 16hrs virtual training for operators.

Single particle mechanical properties test system Display:

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price