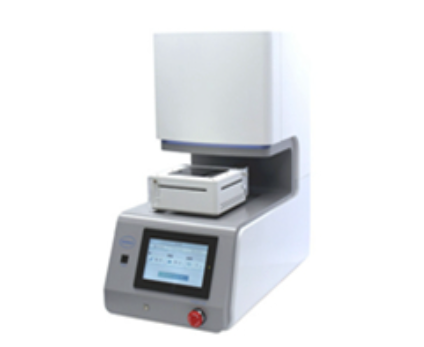

Electronic ink viscosity digital display meter

Standard

- ASTM D445 (Kinematic viscosity of transparent/opaque liquids)

- ISO 2431 (Flow time determination of paints and varnishes)

- GB/T 1723-1993 (China’s national standard for coating viscosity testing)

Product Advantages

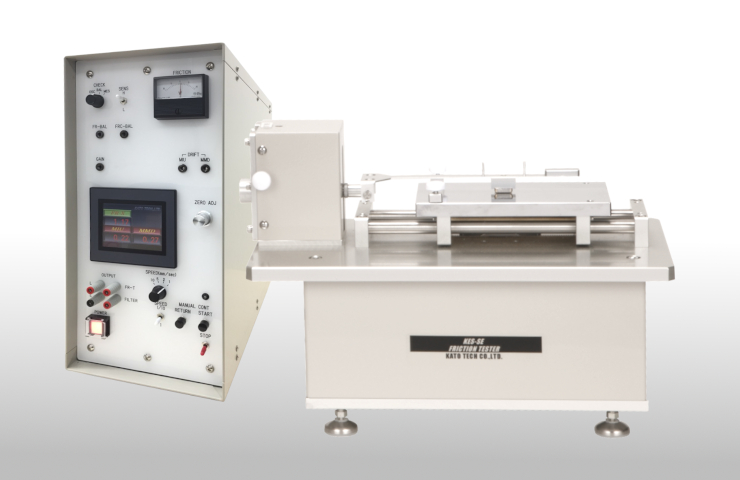

- Shear Force Precision

- Dual-roller system: Metal and rubber rollers rotate at 400–2,000 RPM, measuring ink film separation force with 0.1 unit accuracy.

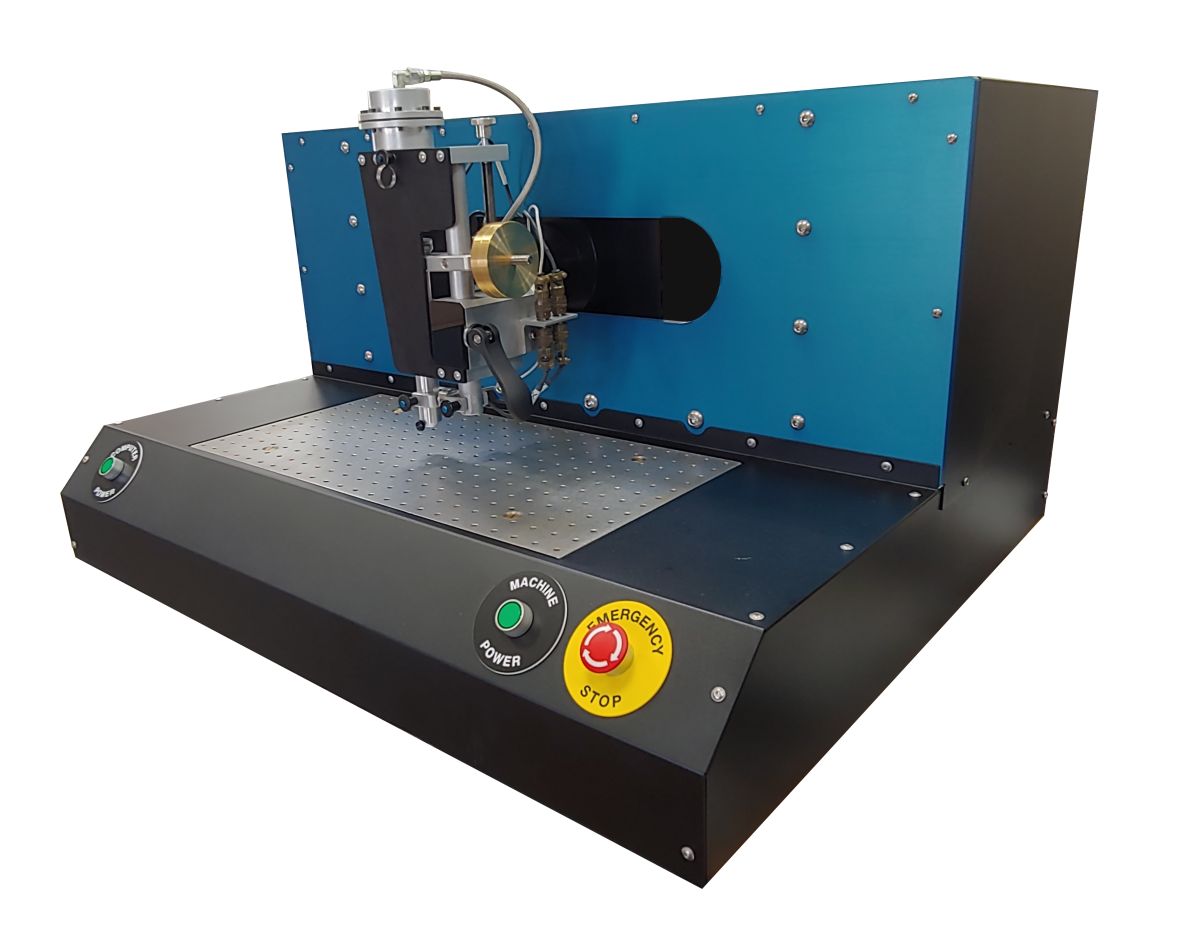

- Temperature-controlled testing: ±0.1°C stability via dual-zone thermostatic water tank (5–80°C range).

- Multi-Speed Adaptability

- 4-speed spindle: 400/800/1,200/1,600 RPM settings for low-to-high viscosity inks (1–10,000 mPa·s).

- Auto-ranging: Adjusts shear rate (1–1,000 s⁻¹) dynamically during testing.

- Smart Calibration

- Automatic zeroing: Compensates for roller misalignment (≤0.03mm level error).

- NIST-traceable calibration: Includes 1,000 mPa·s silicone oil standard for annual ISO 17025 compliance.

- Industrial Durability

- 316L stainless steel rollers with tungsten carbide coating for corrosion resistance.

- IP65 enclosure: Withstands splashes and dust in production environments.

- User-Centric Design

- 2.4" TFT touchscreen: Real-time display of RPM, temperature, and viscosity (0.1 unit resolution).

- Multi-language support: EN/DE/ZH/ES/FR with contextual help menus.

Product Features

- Measurement System:

- Roller configuration: Ø40mm metal roller (60 HRC) and Ø50mm rubber roller (70 Shore A).

- Shear force sensor: 50N load cell with ±0.05N resolution.

- Thermostatic Control:

- Dual-zone water tank: 6L capacity (single-zone) / 8L capacity (dual-zone, ±0.19°C stability).

- Pump flow rate: 10L/min (magnetic drive, silent operation).

- Data Analytics:

- Rheological calculations: Thixotropic index, shear rate, and activation energy (Ea) estimation.

- Export formats: CSV/PDF reports with spectral plots and statistical summaries.

- Safety Features:

- Over-temperature shutdown, emergency ejection button, and anti-slip feet.

- Maintenance:

- Quick-clean rollers: Tool-free removal for solvent washing.

- Self-diagnostics: Roller health monitoring and calibration reminders.

Technical Parameters

| Specification | Details |

|---|---|

| Roller Speed | 400/800/1,200/1,600 RPM (±1% accuracy) |

| Viscosity Range | 1–10,000 mPa·s (auto-ranging) |

| Temperature Control | 5–80°C (±0.1°C single-zone / ±0.19°C dual-zone) |

| Power Consumption | 1,500W (max) / 500W (idle) |

| Display Resolution | 0.1 ink viscosity unit |

| Repeatability | ±0.3 units (same-day retest) |

| Dimensions | 450mm (L) x 300mm (W) x 250mm (H) |

| Weight | 25kg (net) / 30kg (with accessories) |

Accessories Included

- Roller Kit – Metal and rubber rollers (316L stainless steel/silicone rubber).

- Calibration Set – NIST-traceable silicone oil (1,000 mPa·s).

- Thermostatic Water Tank – Dual-zone 8L capacity with magnetic pump.

- Software License – Lifetime access to InkRheo Pro (cloud-connected with API for integration with MIS systems).

- Installation & Training – On-site setup by certified engineers + 8hrs virtual training for operators.

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price