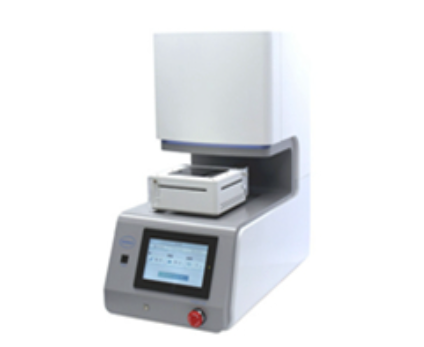

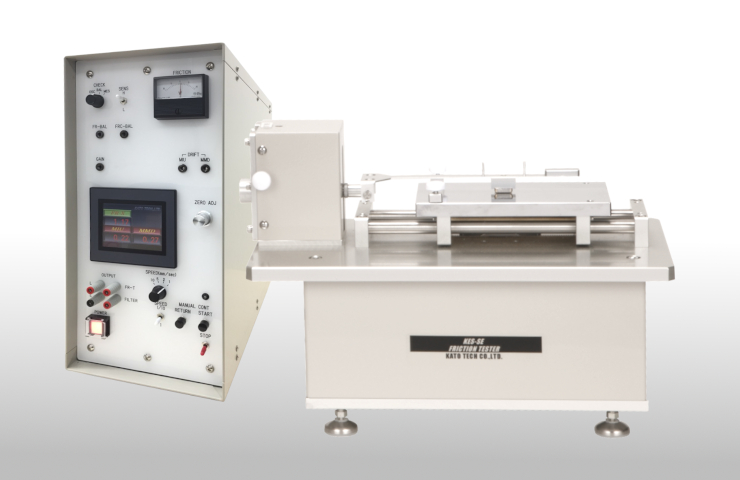

Molten Metal Splash Impact Resistance Tester

Resistance Tester for Molten Metal Droplet (Splash) Impact Performance

This resistance tester for molten metal droplet (splash) impact performance is developed in accordance with testing standards such as ISO 9150, EN 348, GB/T 17599, AQ6103, GB 8965.2, etc. It is applicable to the protective performance of various fabrics and composite fabrics against burns caused by molten metal splashes on the human body. Its testing principle is to determine the number of molten droplets required for the temperature rise of 40K behind the sensor when metal droplets impact the specimen at a certain angle.

Standards:

ISO 9150、EN 348、GB/T 17599、AQ 6103、GB 8965.2

Product Advantages:

The Resistance Tester for Molten Metal Droplet (Splash) Impact Performance offers several key advantages for evaluating protective clothing materials:

Simulates Specific Hazard: Accurately replicates the specific hazard of small molten metal splashes, providing relevant performance data.

Quantitative Performance Data: Provides objective data on the number of droplets the material can withstand before a critical temperature rise occurs.

Supports Standard Compliance: Designed to meet the requirements of multiple international and national standards, essential for product certification and market access.

Evaluates Thermal Protection: Directly assesses the material's ability to prevent heat transfer from molten metal, the primary cause of burns.

Aids Material Selection and Development: Helps manufacturers select appropriate materials and develop new fabrics with enhanced protection against molten metal splashes.

Ensures Worker Safety: By enabling rigorous testing, the instrument contributes to the development and use of effective protective clothing, enhancing worker safety.

Includes Safety Features: Equipped with protective measures to ensure the safety of the testing personnel.

Product Features:

The Resistance Tester for Molten Metal Droplet (Splash) Impact Performance is equipped with specialized features to accurately and safely perform the test according to the relevant standards. These include:

Oxygen and acetylene flow regulation devices, which can provide standard gas flow for welding nozzles. Precise control of gas flow is essential for generating molten droplets of consistent size and temperature.

Oxygen and acetylene pressure regulation devices, which can precisely control the inlet pressure to 250Kpa and 50Kpa. Accurate pressure control ensures stable gas delivery to the torch.

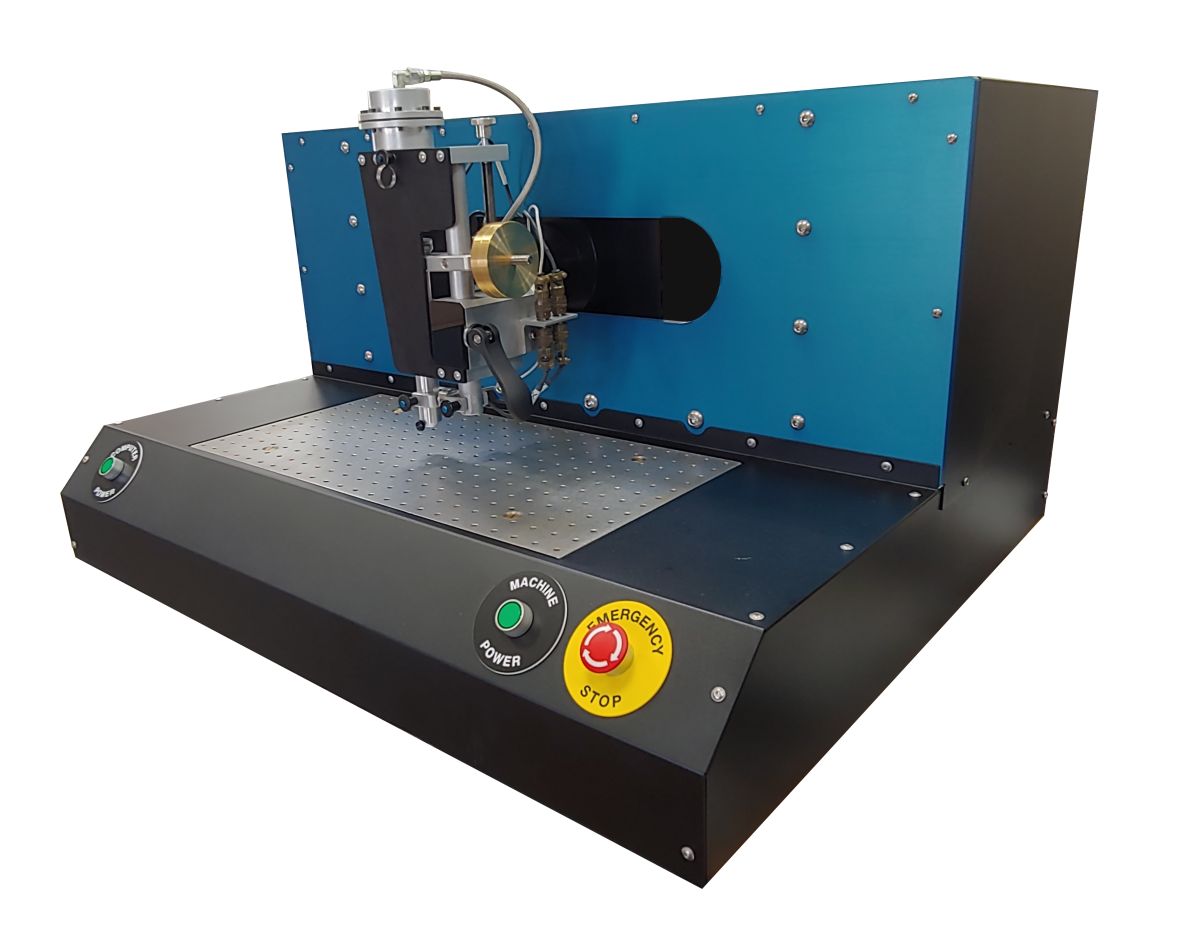

Oxyacetylene welding torch for melting metal strips, with a welding nozzle diameter of (1.2 ± 0.1) mm. The torch and nozzle are designed to melt the metal and form droplets of a specific size as required by the standards.

A stepper motor is used to drive the metal strip, and the running speed of the metal strip can be set. Controlling the speed at which the metal strip is fed into the flame regulates the droplet formation frequency and size.

Droplet guiding mechanism, equipped with a high-temperature anti-sticking guide groove, with an angle of 45 degrees. This mechanism ensures that the molten droplets are directed towards the test specimen at the specified impact angle, and the anti-sticking feature prevents interference with droplet trajectory.

Technical Parameters of the Resistance Tester for Molten Metal Droplet (Splash) Impact Performance:

- Oxygen and acetylene flow regulation devices, which can provide standard gas flow for welding nozzles.

- Oxygen and acetylene pressure regulation devices, which can precisely control the inlet pressure to 250Kpa and 50Kpa.

- Oxyacetylene welding torch for melting metal strips, with a welding nozzle diameter of (1.2 ± 0.1) mm.

- A stepper motor is used to drive the metal strip, and the running speed of the metal strip can be set.

- Droplet guiding mechanism, equipped with a high-temperature anti-sticking guide groove, with an angle of 45 degrees.

- Fabric temperature measurement sensor device, including a refractory insulating rock wool support block and an armored platinum resistance thermometer, for measuring the temperature rise on the back of the specimen.

- Counterweight copper hammer device, used to set a pre-tension of 175g ± 0.5g for the fabric.

- A droplet counting device is provided, which can display the number and frequency of droplets during the test.

- Equipped with standard testing software for resistance to molten metal splash impact performance, with a touch screen human-machine interface control, which can display test parameters such as temperature rise curves.

The whole machine is equipped with a protective cover to protect the safety of testers.

Leave Message Get Price