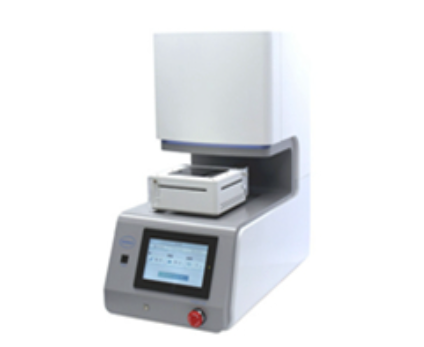

Carpet Pilling and Tufting Performance Tester

This instrument is designed to assess the pilling and tufting performance of carpets during use and is suitable for all circular-woven floor coverings.

Test Method:

The carpet abrasion resistance tester includes two cubic-shaped test chambers with removable covers. Each chamber evaluates two carpet samples, which are fixed to the cover surface using double-sided tape. Two weighted rubber tubes are placed inside each chamber, followed by closing the lid. The chambers rotate at 50 revolutions per minute (RPM) until a preset rotation count is reached, with the rotation direction changing periodically.

Features and Advantages:

- PLC-controlled rotation direction for precise operation.

- Compact rotating test chambers with easy-to-open lids for efficient handling.

- Preset counter to specify the required rotation count.

- Equipped with 8 weighted rubber tubes for standardized testing.

- Acrylic safety shield ensures visibility and operational safety.

- Optional accessory operation display (illustrated) to monitor device status.

Complies with standard: IWS TM 253.

Standard:

IWS TM 253: This standard specifies a test method for evaluating the appearance retention, particularly pilling and tufting, of carpets through a controlled tumbling and abrasion process. The design and operation of the tester are in accordance with the requirements outlined in IWS TM 253.

Scope of Application:

This instrument is designed to assess the pilling and tufting performance of carpets during use and is suitable for all circular-woven floor coverings. By simulating the abrasive forces and mechanical action that occur on carpet surfaces due to foot traffic and cleaning, the tester accelerates the wear process in a controlled laboratory environment. The results allow manufacturers, researchers, and quality control personnel to evaluate the inherent resistance of different carpet constructions and materials to pilling and tuft loss.

Technical Parameters:

Number of Test Chambers: 2

Test Chamber Type: Cubic

Rotation Speed: 50 RPM

Rotation Direction Change: Periodic (as indicated by the test method description), controlled by PLC.

Counter Range: (Typically configurable to a high number of rotations, e.g., up to 999.999 cycles or more)

Number of Weighted Rubber Tubes Provided: 8 (as indicated by the features)

Weight of Rubber Tubes: (Standardized weight as specified by IWS TM 253)

Sample Size: (Typically requires samples cut to a specific size to fit the test chamber covers, as specified by IWS TM 253)

Power Supply: (e.g., AC 110V or 220V, 50/60 Hz)

Leave Message Get Price