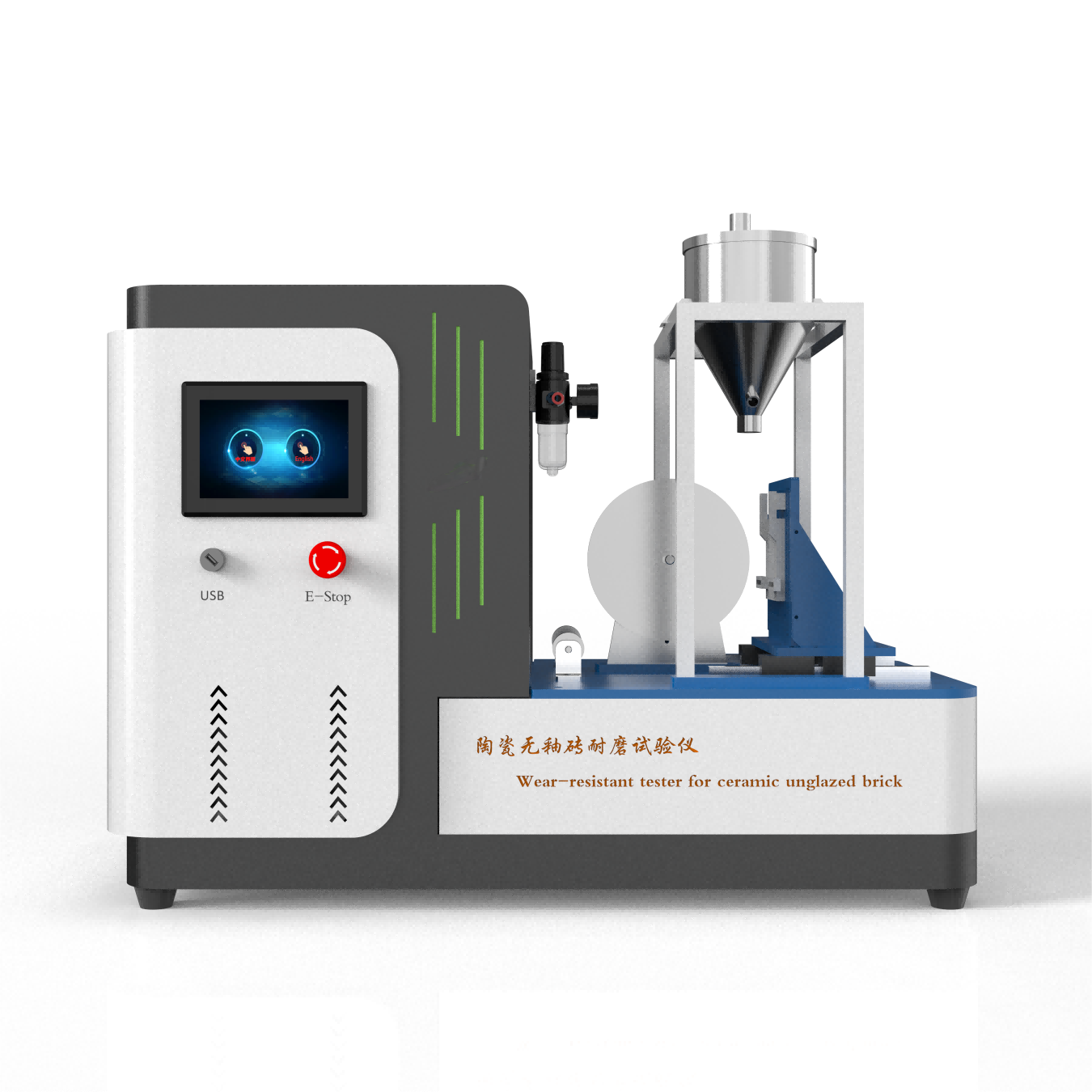

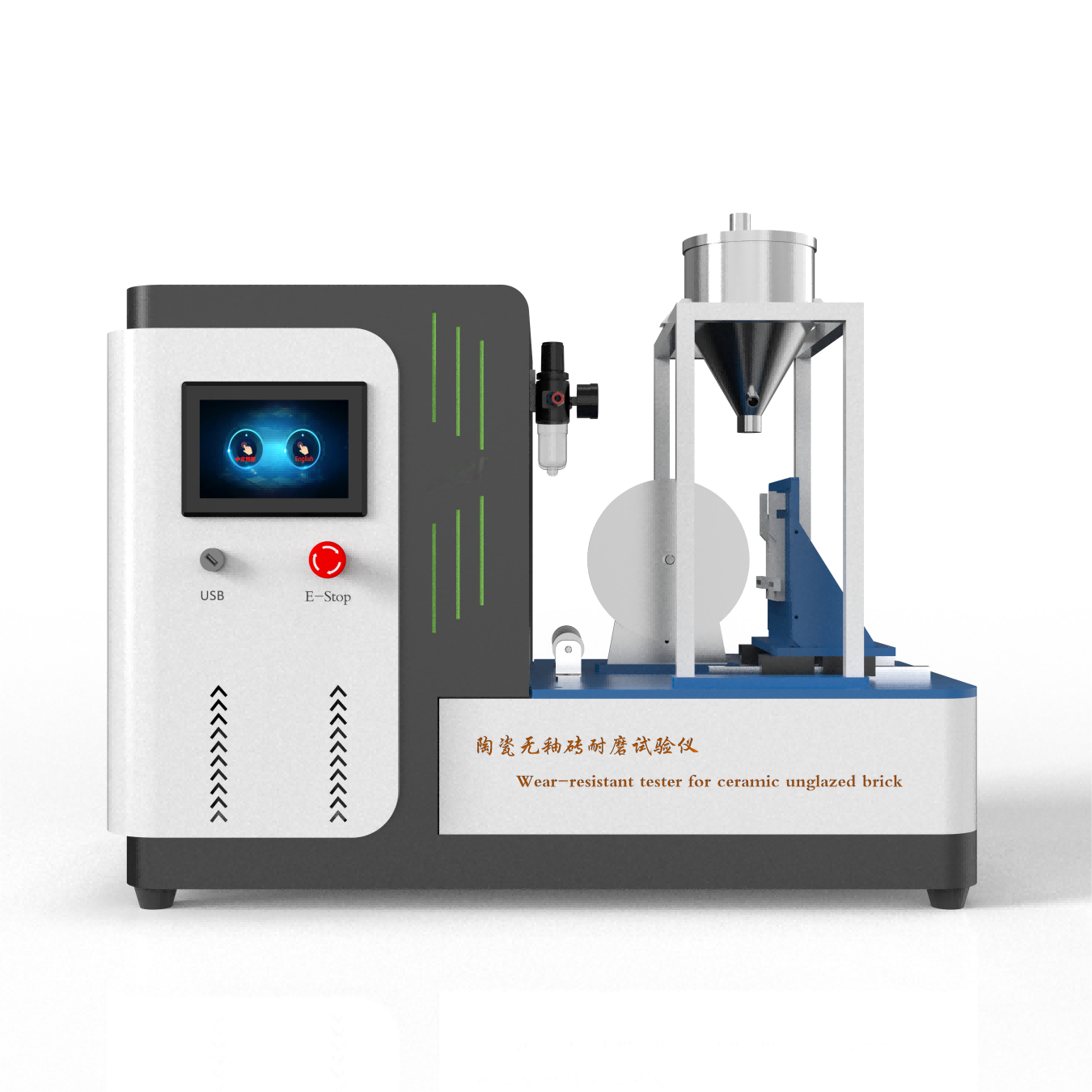

Unglazed ceramic tile wear tester

Standard

- GB/T 3810.6-2016 (China’s regulatory standard for wear resistance testing of unglazed bricks and mosaics)

- ISO/DIS 10545-6 (International standard for abrasion resistance testing of unglazed ceramic tiles)

- ASTM C1243 (Standard test method for resistance to abrasion of resilient floor coverings using an abraser with rotating cylindrical drums)

Product Advantages

- Precision Abrasion Control

- 75rpm steel wheel rotation with ±0.5rpm accuracy for consistent wear patterns (per GB/T 3810.6).

- Automated abrasive feed: 100g/100r ±10g sand delivery system for repeatable testing.

- Universal Compliance

- Preloaded test protocols for GB/T 3810.6, ISO 10545-6, and ASTM C1243 standards.

- Sample flexibility: Accepts tiles up to 300mm x 300mm (12" x 12") with thicknesses from 5mm to 20mm.

- High-Speed Data Acquisition

- 10kHz sampling rate captures wear progression in real time, critical for analyzing surface degradation under cyclic loading.

- User-Centric Design

- 7" HMI touchscreen with multi-language interface (EN/DE/ZH/ES/FR) and one-touch test report generation (PDF/CSV).

- Modular design for quick-change steel wheels and abrasive hoppers.

- Industrial Durability

- AISI 304 stainless steel chassis with anti-vibration mounting and IP54 dust/water resistance.

Product Features

- Abrasion System:

- Steel wheel: Ø200mm x 50mm (AISI 1045 carbon steel, 60 HRC hardness).

- Abrasive feed: 100g/100r ±10g sand delivery (calibrated per GB/T 3810.6).

- Load application: 1000g ±1g counterweight for standardized pressure on tile surface.

- Control System:

- PLC automation with PID closed-loop control maintains ±0.5rpm speed accuracy.

- 7" touchscreen with embedded test protocols for GB/T 3810.6 and ISO 10545-6.

- Data Analytics:

- Built-in software calculates abrasion resistance index (ARI), mass loss (g), and surface roughness (Ra).

- Exportable reports with wear progression curves and compliance certifications.

- Sample Handling:

- Vacuum suction system for secure tile fixation (300mm x 300mm max).

- Adjustable tile thickness accommodation (5mm–20mm).

- Safety Features:

- Dual-channel emergency stop, overload protection (150% F.S.), and HEPA-filtered dust extraction.

Technical Parameters

| Specification | Details |

|---|---|

| Steel Wheel | Ø200mm x 50mm (AISI 1045 steel, 60 HRC) |

| Rotation Speed | 75rpm ±0.5rpm (adjustable via servo motor) |

| Abrasive Feed | 100g/100r ±10g (calibrated per GB/T 3810.6) |

| Sample Size | 300mm x 300mm (max) / 5mm–20mm (thickness) |

| Load Application | 1000g ±1g counterweight |

| Measurement Accuracy | ±0.1g mass loss / ±0.5μm surface roughness |

| Power Requirements | 110V/220V AC, 50/60Hz, 600W |

| Operating Temperature | 15–35°C (±1°C stability) |

| Footprint | 800mm (L) x 600mm (W) x 1,200mm (H) |

| Weight | 120kg (net) / 150kg (with abrasive system) |

Accessories Included

- Steel Wheel Set – Ø200mm x 50mm AISI 1045 steel wheels (60 HRC hardness).

- Abrasive Kit – 25kg silica sand (GB/T 3810.6 compliant, 0.1–0.5mm particle size).

- Calibration Tools – NIST-traceable mass set and surface roughness comparator.

- Software License – Lifetime access to AbrasionLab Pro (cloud-connected with API for integration with LabVIEW/MATLAB).

- Installation & Training – On-site setup by certified engineers + 16hrs virtual training for operators.

Unglazed ceramic tile wear tester Display:

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price