Automobile seat headrest static strength tester

Compliance Standards

- FMVSS 202a (Head Restraints)

- ECE R17 (Strength of Seats)

- ISO 17373 (Road vehicles - Head restraints)

- SAE J3668 (Head Restraint Testing)

- GMW14205 (GM Head Restraint Spec)

Technical Parameters

| Parameter | Specification |

|---|---|

| Max Load Capacity | 5000N (±0.5% FS) |

| Force Resolution | 0.1N |

| Displacement Accuracy | ±0.01mm |

| Test Speed | 0.1-500 mm/min |

| Test Dimensions | H: 500-1200mm W: 400-800mm |

| Power Supply | 3PH 400VAC 50/60Hz |

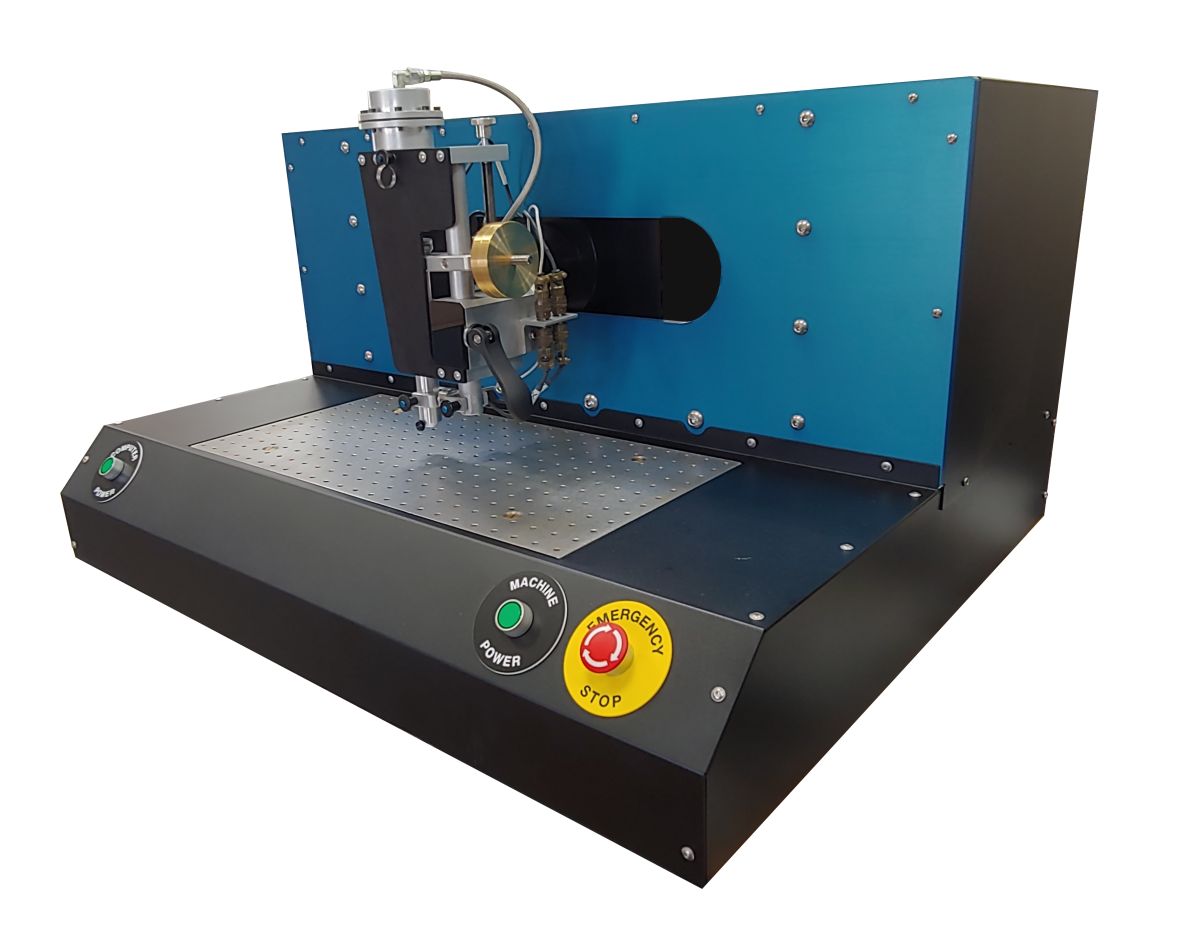

Key Features

- Multi-axis force application system

- Real-time deformation monitoring

- Automatic test sequence control

- FMVSS 202a compliance package

- Structural failure detection

Test Capabilities

| Test Type | Standard | Measurement |

|---|---|---|

| Rearward Strength | FMVSS 202a S5 | Up to 890N |

| Height Retention | ECE R17 | ≤25mm displacement |

| Angular Deflection | ISO 17373 | ±0.1° accuracy |

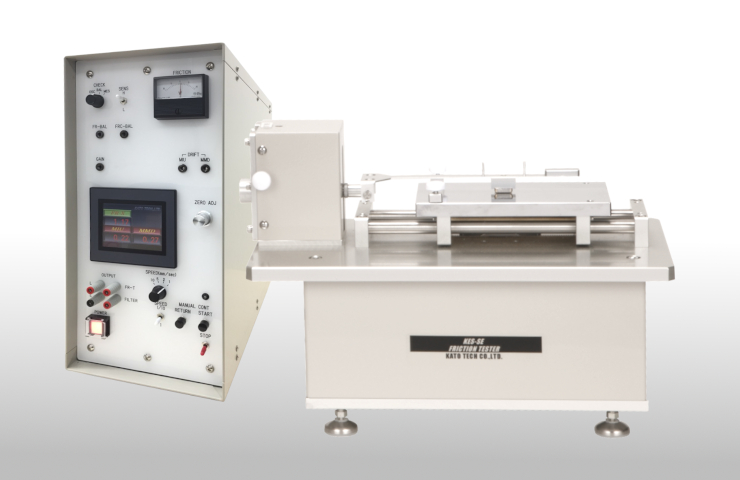

Measurement System

- S-type load cell (Class 0.5)

- Laser displacement sensors

- Digital angle encoder

- 1000Hz data acquisition

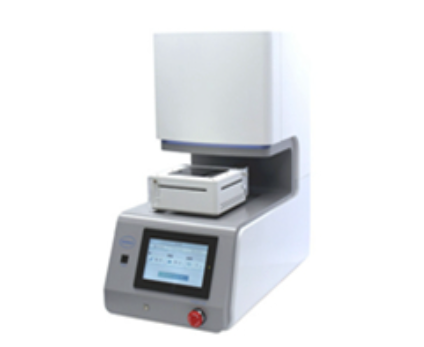

Standard Configuration

- Adjustable test frame (W800×H1500mm)

- Headrest mounting adapters (3 types)

- Safety enclosure with viewing window

- StrengthTest Pro software

Automotive Options

- Active headrest mechanism tester

- High-speed camera system

- Thermal chamber (-40°C to +85°C)

- 3D deformation scanner

Safety Systems

- Emergency stop with mechanical lock

- Overload protection circuit

- Safety light curtains

- Automatic specimen release

Main parameters:

Load capacity: The maximum static load that the tester should be able to withstand. This parameter is usually determined according to the design and requirements of the headrest, and the common load capacity range is 500kg or higher.

Load accuracy: The measurement accuracy of the tester when a static load is applied. This parameter is crucial for assessing the static strength of the headrest, with common load accuracy of ±1% or higher.

Displacement range: The maximum amount of displacement that the tester can measure during the test. This parameter is usually determined according to the design and requirements of the headrest, and the common displacement range is between 300mm and 400mm.

Displacement accuracy: The accuracy of the tester when measuring displacement. This parameter is also important for evaluating the static strength of the headrest, with common displacement accuracy of ±1% or higher.

Test speed: Although the static strength test is mainly concerned with the measurement of load and displacement, the tester usually has a certain test speed control function to adapt to different test needs. The test speed can usually be adjusted within a certain range, such as 10-30 times/minute.

Control mode: The control mode of the tester may include manual control and automatic control. Modern tester usually adopts computer automatic control mode to improve the accuracy and efficiency of the test.

Test device: The test device shall include a stable support for fixing the car seat and headrest; A loadable static load device for applying a static load; And the necessary sensors and data acquisition systems for real-time monitoring and recording of various parameters during the test.

Safety protection: The tester should have perfect safety protection measures, such as overload protection, emergency stop button, etc., to ensure the safety and reliability of the test process.

Leave Message Get Price