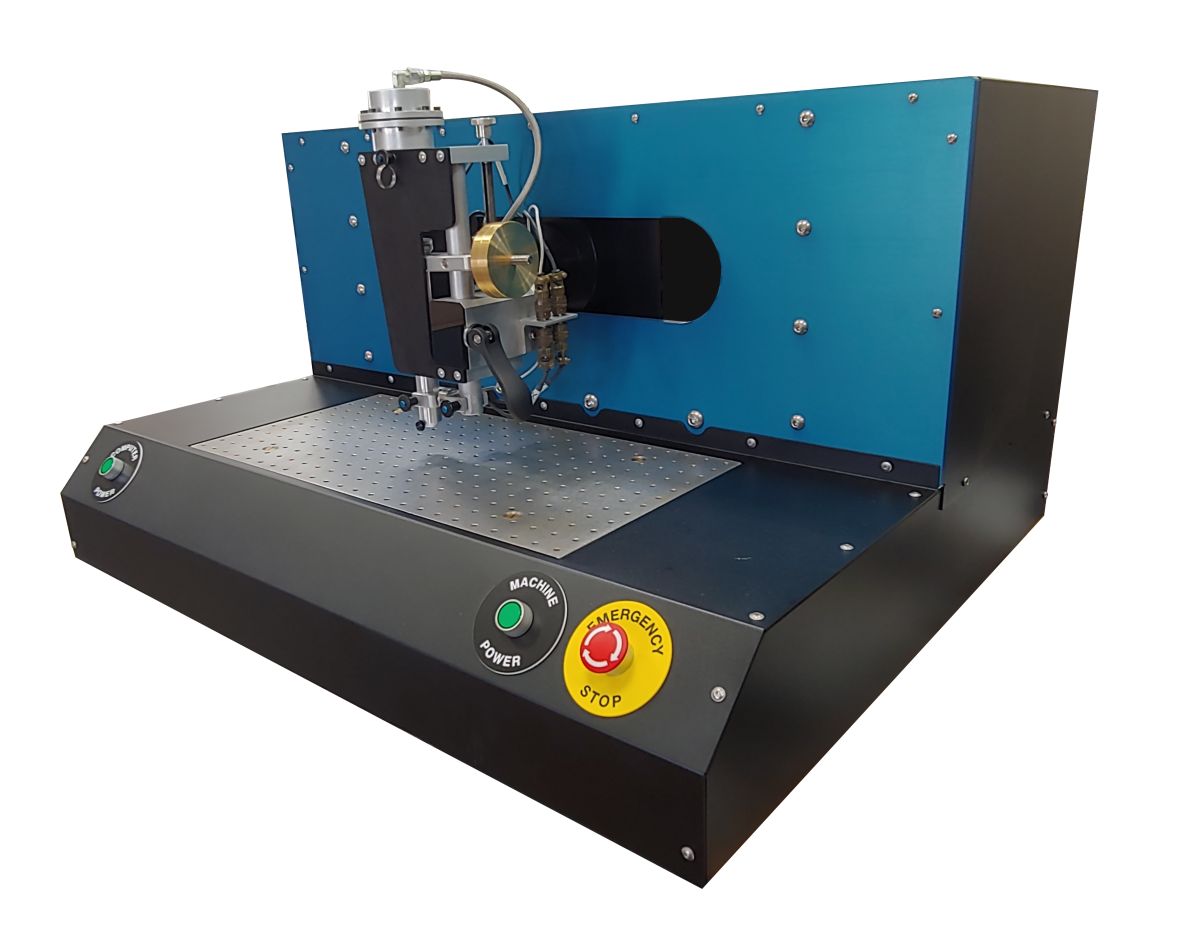

Automobile seat static strength tester

Compliance Standards

- ASTM D4329, D4587, D4799, D5208, G151, G154

- EN 927-6, 1297, 1898 FIBC, 12224, 13523-10, 1062-4

- ISO 4892-1, 4892-3, 11507, 11895, 11997-2

- SAE J2020

Product Advantages

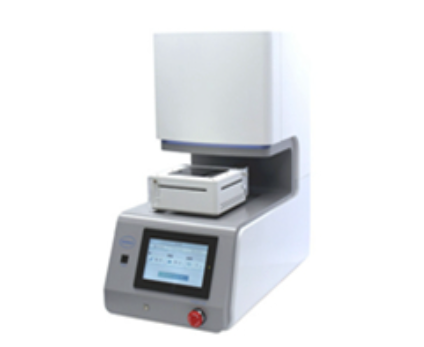

Our UV aging chamber features an innovative design that outperforms conventional UV fluorescent aging test chambers. It combines high performance with enhanced ease of use, precision, and safety, meeting or exceeding verification standards of leading brands. Key features include:

- Multi-language touch screen interface

- Ethernet connectivity for secure data collection

- Optional recirculating spray system

- Intuitive user-friendly operation features

Product Features

- 8 × 40W UV fluorescent lamps

- Black Panel Temperature (BPT) control

- Dual safety protection system (hardware + software)

- CE compliant with UL & CSA certifications

- Touch screen interface with sample fixation rings

- Irradiance calibration safety port

- Low water level & over-temperature protection

- Specimen rack capacity: 48 samples

Technical Parameters

| Radiation Uniformity | ≤4% across sample surface |

| Irradiance Range | UVA: 0.35-1.55 W/m² UVB: 0.35-1.23 W/m² |

| BPT Range | UV Stage: 35-80°C (95-176°F) Condensation: 35-60°C (95-140°F) |

| Sample Capacity | 48 samples + 24 BPT clamps |

| Weight | 140 kg (310 lb) ± accessories |

| Power Requirements | 120VAC (±10%), 12A or 230VAC, 8A |

| Water Specifications | Pressure: 25-40 psi (1.7-2.7 bar) Purity: <1 ppm TDS, <0.1 ppm Si |

Standard Accessories

- Recirculating water spray system

- 12 standard nozzles

- Handheld radiometric calibrator

- Ethernet data acquisition software

- Stacking kit

- Radiation control modules (340/313/351 nm)

Customizable nozzle configurations

Main parameters:

Load measurement range: The load measurement range of the tester is usually between (40 to 2000)N, depending on the model and configuration of the tester. This parameter determines the maximum and minimum loads that the tester can measure.

Load accuracy: Load accuracy is usually expressed as the percentage error of the measured value, generally around ±1%. This parameter reflects the accuracy and reliability of measuring load of the tester.

Load cylinder stroke: The load cylinder stroke refers to the maximum distance that the tester can move during the loading process, usually around 500mm. This parameter determines the range of loads that the tester can simulate.

Displacement accuracy and resolution: Displacement accuracy is usually expressed as a percentage error or absolute error of the measured value, while displacement resolution refers to the smallest change in displacement that the tester can detect. These parameters affect the accuracy and sensitivity of measuring displacement.

Angular displacement measurement and control accuracy: For test items that need to measure angular displacement, the tester should have sufficient angular displacement measurement and control accuracy, usually around ±0.01°. This parameter reflects the accuracy and stability of the tester when measuring angular displacement.

Sampling frequency: Sampling frequency refers to the rate at which the tester collects data during the test, usually around 1000Hz. The high sampling frequency ensures that the tester can capture more data points, which improves the accuracy and reliability of the test.

Equipment power supply: The tester usually needs a single-phase AC220V, 50Hz power supply, the power depends on the tester model and configuration.

Software functions: The tester is usually equipped with professional test software for controlling the test process, collecting and processing data. The software functions should include manually setting conditions to find the feature points of the curve, obtaining the slope between two points of any curve, scaling and moving the curve, exporting all test sampling points to Excel, etc.

Leave Message Get Price