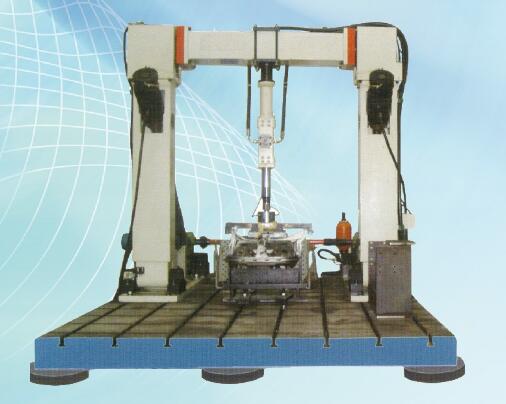

Automobile seat fatigue tester

Compliance Standards

- SAE J2380 (Vibration Durability)

- ISO 16840 (Seat Fatigue Requirements)

- FMVSS 207/210 (Seat System Integrity)

- VW PV 3925 (Cyclic Endurance Test)

- GMW14193 (GM Seat Durability)

Technical Parameters

| Parameter | Specification |

|---|---|

| Load Capacity | ±15kN (Dynamic) |

| Frequency Range | 0.1-50Hz |

| Actuator Stroke | ±150mm |

| Test Axes | 6-DOF (X,Y,Z,Rx,Ry,Rz) |

| Position Accuracy | ±0.1mm |

| Temperature Range | -40°C to +85°C |

| Cycle Lifetime | 10⁷ cycles at max load |

Key Features

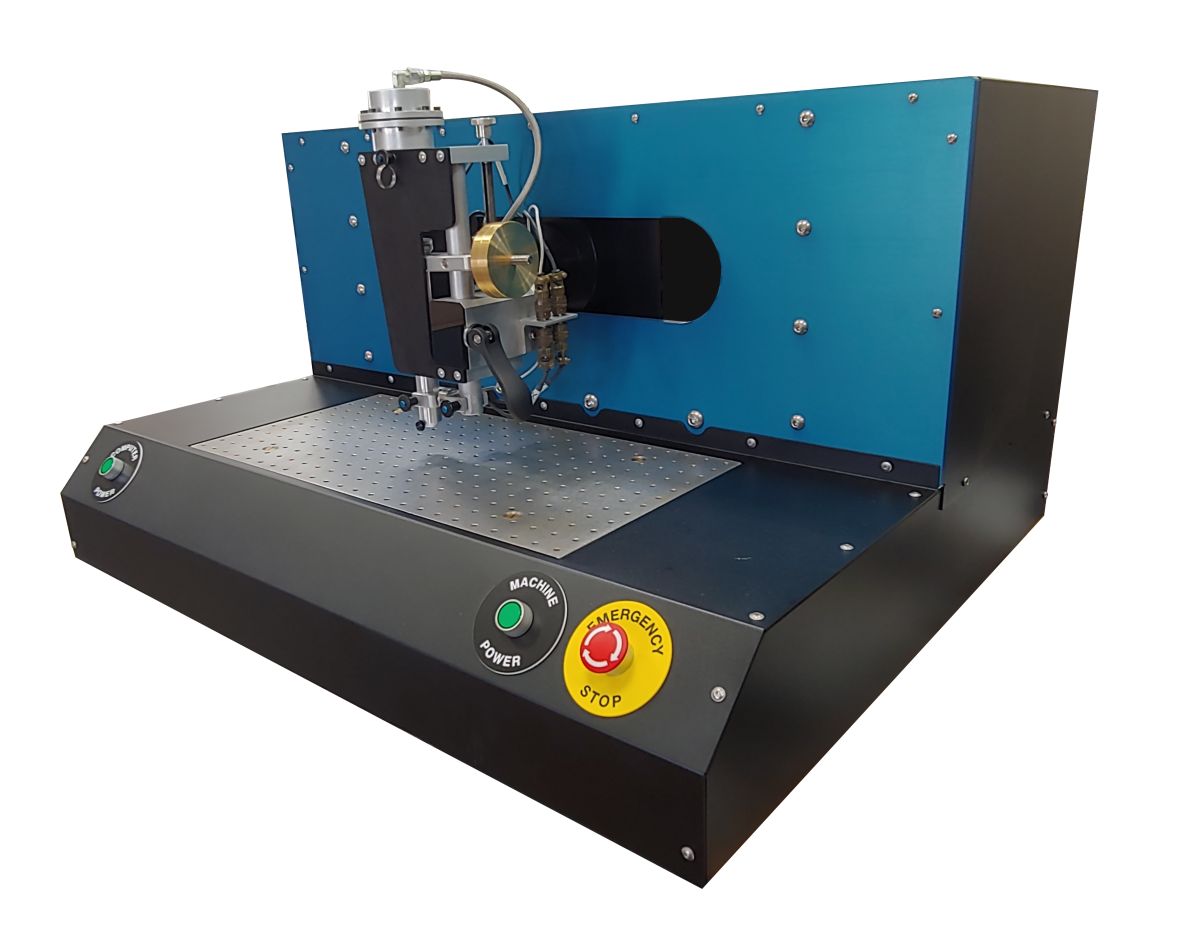

- Multi-axis servo-hydraulic actuation

- Real-time crack detection system

- Road load data replication

- Smart predictive maintenance

- FEA validation interface

Test Capabilities

| Test Type | Standard | Description |

|---|---|---|

| Static Fatigue | FMVSS 207 | 150% overload capacity |

| Dynamic Vibration | SAE J2380 | 0-50Hz random vibration |

| Thermal Cycling | VW PV 3925 | Temperature shock testing |

Measurement System

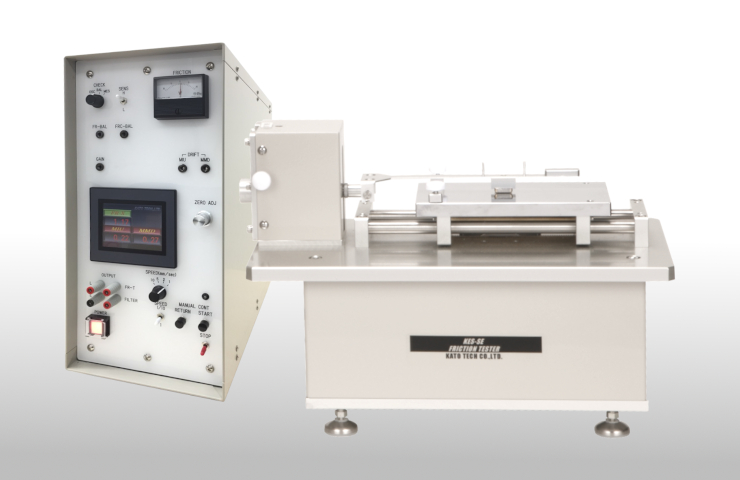

- 16-channel strain gauge inputs

- 1000Hz data acquisition

- Laser displacement sensors

- Acoustic emission monitoring

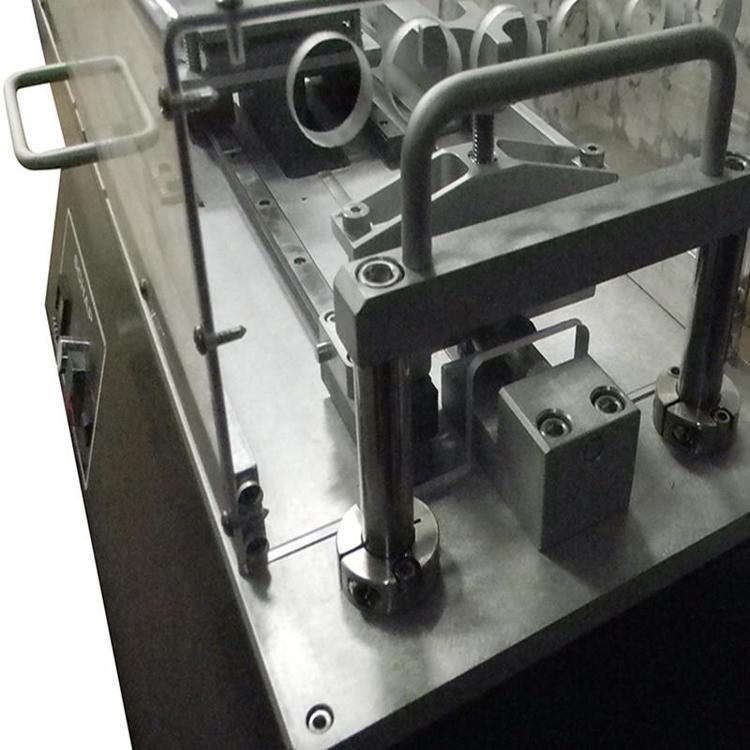

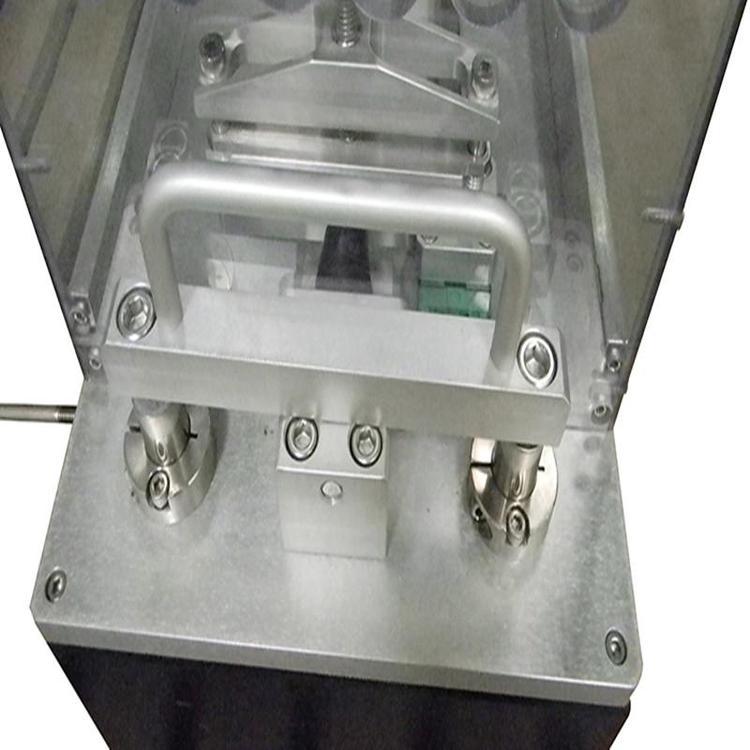

Standard Configuration

- Hydraulic power pack (100L/min)

- Universal seat mounting jig

- Basic environmental chamber

- FatigueSoft Pro software

Premium Options

- Multi-axis vibration table

- Corrosion simulation chamber

- AR/VR failure visualization

- AI-based pattern recognition

Safety Systems

- Emergency pressure relief

- Overload protection (mechanical/electronic)

- Safety light curtains

- Automatic shutdown protocol

Main parameters:

Loading impact force: The tester usually has a certain range of loading impact force, which is used to simulate the load borne by the seat in actual use. For example, some models of testers can load impact forces up to 750N or higher.

Reciprocating compression frequency: The reciprocating compression frequency of the tester indicates the number of compression-release cycles performed per unit time. This parameter can usually be adjusted within a certain range to suit different test requirements. For example, some models of testers can compress up to 75 times/minute or more.

Reciprocating compression stroke: The reciprocating compression stroke refers to the maximum distance the tester moves during compression. This parameter determines the range of loads that the tester can simulate. In general, reciprocating compression stroke between 150mm and 180mm is more common.

Disc diameter: The disc is a component used to apply loads, and its diameter can affect the accuracy and reliability of test results. The diameter of the pressure disc may vary from model to model.

Number of tests: The tester can usually set the number of tests to achieve a predetermined test cycle. The number of tests should be set according to the specific test criteria and seat type.

Display and control: Modern car seat fatigue testers are usually equipped with advanced display and control systems, which can display various data in the test process in real time, such as load, displacement, time, etc., and can accurately control the test parameters.

Safety performance: The tester should have perfect safety protection measures, such as overload protection, emergency stop button, etc., to ensure the safety and reliability of the test process.

Leave Message Get Price