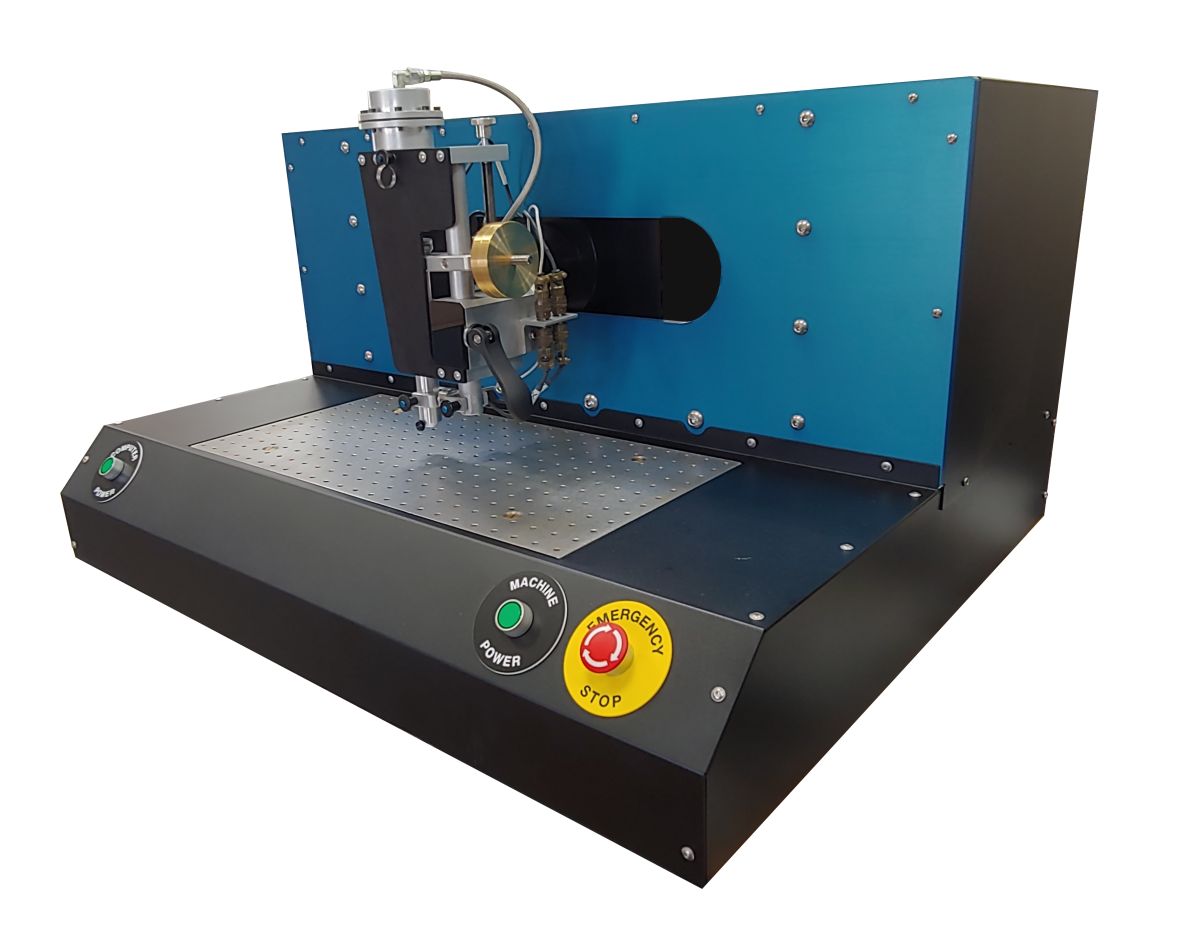

Automobile seat frame durability tester

Compliance Standards

- ISO 12100 (Safety of machinery)

- SAE J879 (Vehicle Seat Strength Test)

- FMVSS 207/210 (Seat System Integrity)

- VW PV 3925 (Seat Frame Durability)

- GMW14193 (GM Seat Structure Test)

Technical Parameters

| Parameter | Specification |

|---|---|

| Load Capacity | ±50kN (Dynamic) ±100kN (Static) |

| Frequency Range | 0.1-50Hz |

| Actuator Stroke | ±150mm |

| Test Axes | 6-DOF (X,Y,Z,Rx,Ry,Rz) |

| Position Accuracy | ±0.1mm |

| Data Channels | 32 synchronous inputs |

Key Features

- Multi-axis servo-hydraulic system

- Real-time crack detection system

- Thermal cycling (-40°C to +120°C)

- Strain gauge integration

- FEA correlation interface

Test Capabilities

| Test Type | Standard | Cycle Capacity |

|---|---|---|

| Static Overload | FMVSS 207 | 1-10 cycles |

| Fatigue Test | VW PV 3925 | 1,000,000+ cycles |

| Crash Simulation | ECE R17 | 20g acceleration |

Measurement System

- 1000Hz data acquisition

- 16-channel strain measurement

- Laser displacement sensors

- Acoustic emission monitoring

Standard Configuration

- Modular test frame (2000×3000mm)

- Universal seat mounting fixtures

- Hydraulic power unit (100L/min)

- DuraTest Pro software package

Automotive Options

- Corrosion test chamber

- Multi-body dynamics interface

- AR/VR failure visualization

- AI-based predictive maintenance

Safety Systems

- Emergency pressure relief

- Load path monitoring

- Seismic restraint system

- Double safety interlock

Main parameters:

Impact speed: The impact speed of the tester is usually between 25 and 30km/h, which is a key parameter to simulate vehicle collision or deceleration. The specific speed value should be determined according to the test criteria and the type of seat.

Impact head type: Impact head type is a component that simulates the shape and quality of the passenger head, and its parameters such as diameter and equivalent mass should meet the requirements of relevant standards. The common impact head type has a diameter of 165mm and an equivalent mass of about 6.8kg.

Measurement accuracy: The measurement accuracy of the tester includes impact velocity measurement accuracy, acceleration measurement accuracy, etc. These precision parameters determine the accuracy and reliability of the test results. Generally speaking, the impact velocity measurement accuracy should be about ±1%, and the acceleration measurement accuracy should be about ±3%.

Adjustment range: The impact arm of the tester usually has a large adjustment range in the Z direction to adapt to different seat types and test needs. At the same time, the Angle of the impact arm can also be adjusted to simulate the collision situation at different angles.

Data acquisition and processing: The tester should be equipped with a high-speed data acquisition system, which can record various data in the test process in real time, such as impact speed, acceleration, deceleration, etc. At the same time, the data should be able to be subsequent processed and analyzed to produce accurate test results.

Safety protection: The tester should have perfect safety protection measures, such as safety protection net, emergency stop button, etc., to ensure the safety and reliability of the test process.

Leave Message Get Price