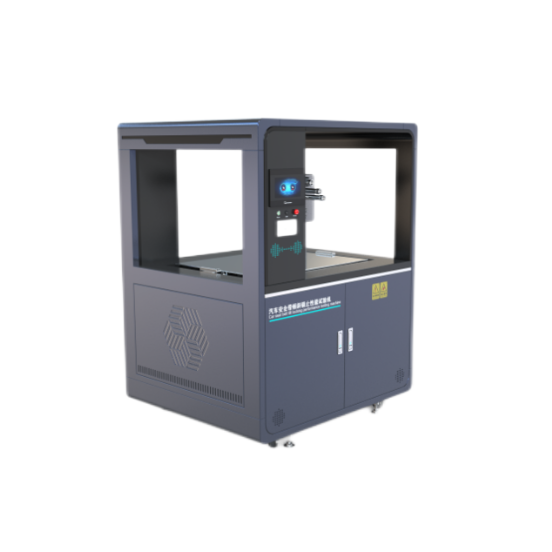

Automobile seat belt locking performance tester

Compliance Standards

- FMVSS 209 (Seat Belt Assemblies)

- ECE R16 (Safety Belt Requirements)

- ISO 13046 (Road Vehicle Seat Belt Testing)

- GB 14166 (China Seat Belt Standard)

JIS D4604 (Japanese Industrial Standard)

Main parameters:

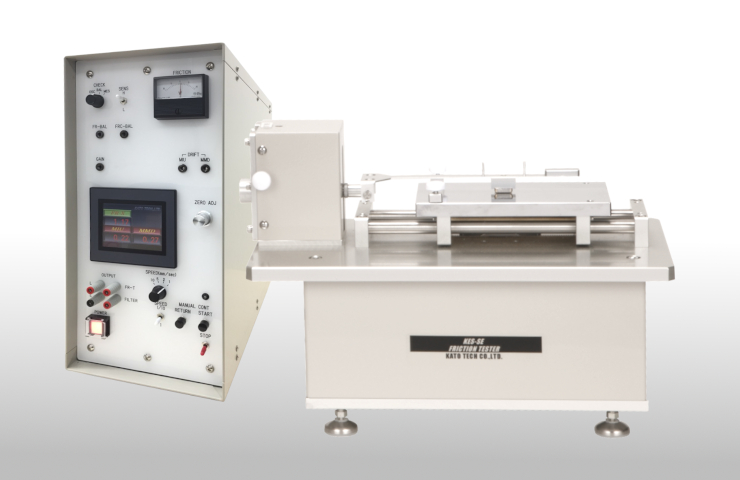

Control system:

PLC control system is usually used to realize automatic control and data processing.

Operation interface:

It is equipped with a color touch screen and supports switching between Chinese and English for easy operation.

Emergency lock test parameters:

After installation, the winder can reach a speed of 2.94m/s within 50ms to simulate the locking function in emergency situations.

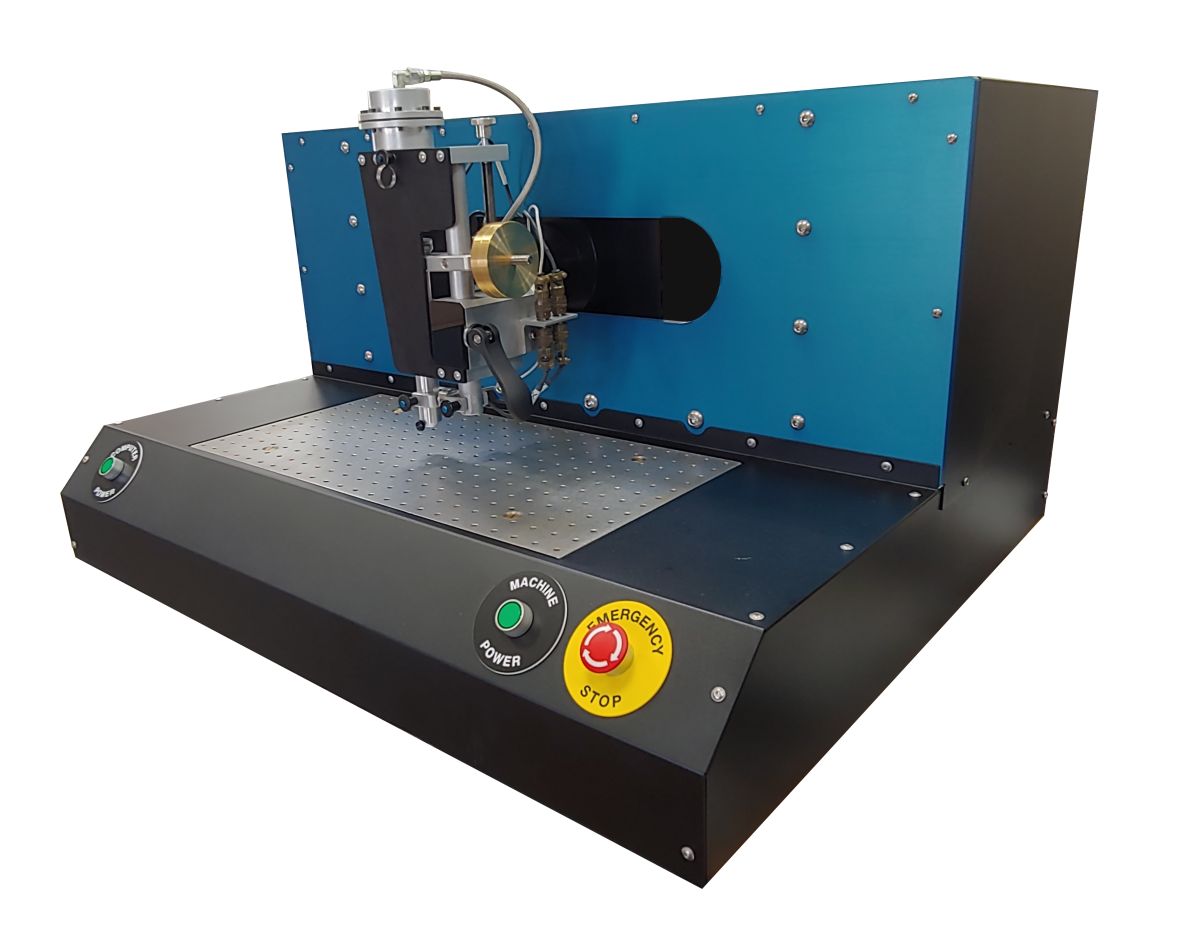

Angle adjustment:

The installation Angle can be adjusted, such as the winding shaft to the horizontal plane of 45°, 90°, 135° and 180° to adapt to different test requirements.

Vehicle acceleration adjustment range:

The acceleration adjustment range is usually 0.2——1.5g (can be set) to meet the needs of different test conditions.

Acceleration adjustment step:

The acceleration adjustment step is usually less than or equal to 0.05g to ensure the accuracy of the test.

Maximum displacement of car feeling:

The maximum displacement of the car is usually 100mm, which is used to simulate the displacement of the vehicle during an emergency stop or collision.

Inductive acceleration adjustment range:

The inductive acceleration adjustment range is not less than 0.2——2.5g to adapt to the test needs of different seat belt materials.

Acceleration measurement accuracy:

The measurement accuracy of acceleration is usually less than 0.01g to ensure the accuracy of the test results.

Repeatability deviation of acceleration:

The repeatability deviation of acceleration is usually less than or equal to ±0.01g to ensure the stability and reliability of the test results.

Maximum overshoot of acceleration:

The maximum overshoot of the acceleration is usually less than 10% of the set acceleration value to ensure the accuracy of the test.

Seatbelt locking distance measurement accuracy:

Seat belt lock distance measurement accuracy is usually less than or equal to ±0.01mm, to ensure the accuracy of the test results.

Key Features

- Emergency Locking Retractor (ELR) verification

- Vehicle deceleration simulation

- Micro-slip measurement (0.01mm)

- Webbing tension profile analysis

- Automatic pretensioner test mode

Test Capabilities

| Test Type | Standard | Parameters |

|---|---|---|

| Emergency Lock Test | FMVSS 209 S4.2 | 0.7g acceleration |

| Webbing Extraction | ECE R16 8.4 | 0.5m/s @ 20N |

| Durability Test | ISO 13046 | 25,000 cycles |

Measurement System

- Laser displacement sensors

- High-speed load cells (10kHz)

- Rotary encoder (0.1° resolution)

- Thermal imaging (lock mechanism)

Standard Configuration

- Servo-electric actuator system

- 3D adjustable belt anchorage

- Crash pulse simulator

- BeltTest Pro analysis software

Automotive Options

- Child seat anchor test kit

- High-speed camera system (10,000fps)

- Environmental chamber (-40°C~+85°C)

- Pretensioner firing system

Safety Systems

- Double emergency stop circuits

- Overload mechanical fuse

- Safety light curtain barrier

- Automatic system deactivation

Test Protocol Example (FMVSS 209)

- Mount seat belt assembly per OEM specs

- Apply 0.7g vehicle deceleration

- Measure lock time ≤50ms

- Verify webbing slippage ≤25mm

- Repeat test at ±30° angles

Maintenance Requirements

- Monthly load cell calibration

- Quarterly actuator alignment

- Annual NIST traceable verification

5-year structural integrity check

Leave Message Get Price