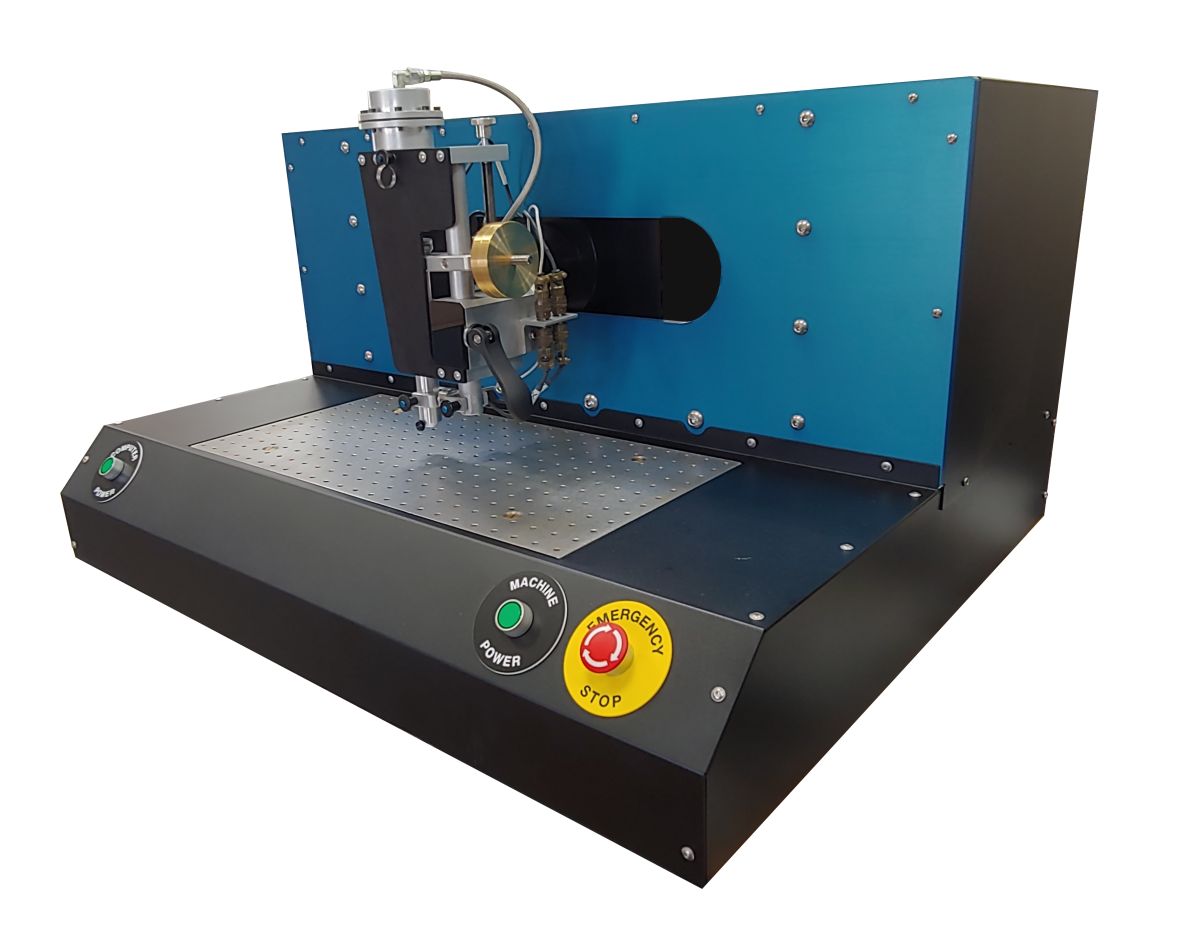

Dental Implant Static Torsion Tester

Standards:

ISO 14801、ASTM A938-18、ASTM F543 、ISO 7206-8、 ISO 7800

Scope of Application:

The static torsion testing machine for dental implants is used to apply a twisting force to a dental implant assembly or its components until failure or a specified torque/angle limit is reached. This test provides critical data for:

Evaluating the torsional strength: Measuring the maximum torque the implant, screw, or connection can withstand before yielding or fracturing.

Assessing torsional stiffness: Determining the resistance to angular deformation under torsional load.

Studying failure modes: Observing how and where failure occurs within the implant, screw, or connection under static torsion (e.g., screw fracture, stripping of threads, fracture of the implant body or abutment).

Verifying tightening torque resistance: Ensuring that screws and connections can withstand the clinically recommended tightening torques without damage.

This data is essential for the design validation, quality control, and regulatory approval of dental implant systems.

Product Advantages:

The Dental Implant Static Torsion Tester offers several advantages for evaluating the torsional integrity of dental implant components:

Precise Measurement: Provides accurate measurement of applied torque and resulting angular displacement.

Evaluates Critical Connections: Specifically designed to test the strength and behavior of the screw-abutment-implant interface, a common site of potential failure.

Reveals Failure Modes: Allows for detailed analysis of how components fail under torsional stress, informing design improvements.

Supports Quality Control: Essential for verifying the manufacturing quality and consistency of implant components.

Aids Research and Development: Provides crucial data for developing new materials, designs, and connection types with improved torsional properties.

Standard Compliant: Enables testing according to relevant international standards.

Product Features:

The static torsion testing machine for dental implants typically has the following technical features and parameters:

Loading system: High-precision motors or hydraulic devices are used as the power source to ensure the stability and accuracy of the loading process, applying a controlled torsional force or angular displacement.

Transmission system: The power from the loading system is transmitted to the dental implant specimen through a precise transmission mechanism to apply torsional force accurately. This often involves a rotary actuator or motor directly connected to the test fixture.

Detection system: Equipped with high-precision torque sensors and angular sensors, it is used to monitor and record in real-time the changes in torque and angle during the torsion process. This data is used to generate torque-angle curves and determine key torsional properties.

Specialized gripping mechanisms and fixtures designed to securely hold the dental implant body, abutment, and/or screw in the correct orientation for applying a pure torsional load to the desired interface or component.

Control software for setting test parameters (e.g., torque rate, angle limit, data acquisition rate), running the test, and performing data analysis (e.g., calculating yield torque, ultimate torque, torsional stiffness).

Ability to perform tests under torque control (applying a constantly increasing torque) or angular displacement control (applying a constantly increasing rotation).

Technical Features and Parameters

The static torsion testing machine for dental implants typically has the following technical features and parameters: - Loading system: High - precision motors or hydraulic devices are used as the power source to ensure the stability and accuracy of the loading process. - Transmission system: The power from the loading system is transmitted to the dental implant specimen through a precise transmission mechanism to apply torsional force. - Detection system: Equipped with high - precision torque sensors and angular sensors, it is used to monitor and record in real - time the changes in torque and angle during the torsion process.

Leave Message Get Price