Scratch Testing Measurement Principle

Heaven developed the scratch test for adhesion evaluation for the first time in 1950. Benjamin and Weaver [2] proposed critical load, Lc, as a quantitative value to evaluate the coating adhesion. The scratch test has become one of the most widely applied methods to evaluate coating adhesion at present. Over the past two decades, this technique is extensively used to assess the adhesion of PVD/CVD deposited superhard nanocomposite coatings, which usually exhibit a high residual stress at the coating/substrate interface.

Moreover, the scratch test is an essential tool for quality control of materials used in wear/abrasive environment, allowing us to detect premature adhesive/cohesive failure of coatings in real-life applications.

Measurement principle

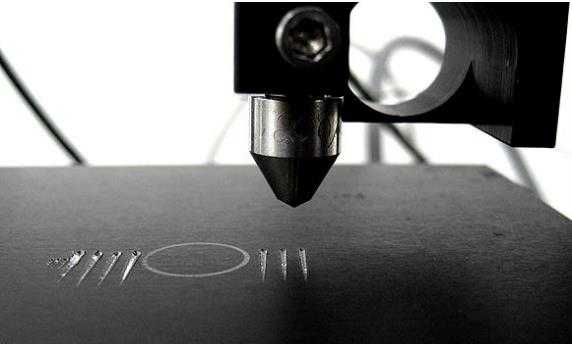

The scratch testing method is a very reproducible quantitative technique. Critical loads at which failures appear are used to compare the cohesive or adhesive properties of coatings or bulk materials. During the test, scratches are made on the sample with a sphero-conical stylus (tip radius ranging from 1 to 200 m) which is drawn at a constant speed across the sample, under a constant load, or, more commonly, a progressive load with a fixed loading rate. Sphero-conical stylus is is available with different radii(which describes the "sharpness"of the stylus). Common radii are from 20 to 200 m for micro/macro scratch tests, and 1 to 20 m for nano scratch tests.

When performing a progressive load test, the critical load is defined as the smallest load at which a recognizable failure occurs. In the case of a constant load test, the critical load corresponds to the load at which a regular occurrence of such failure along the track is observed.

In the case of bulk materials, the critical loads observed are cohesive failures, such as cracking, or plastic deformation or the material. In the case of coated samples, the lower load regime results in conformal or tensile cracking of the coating which still remains fully adherent (which usually defines the first critical load). In the higher load regime, further damage usually comes from coating detachment from the substrate by spalling, buckling

or chipping.

2019-10-11 16:59