Analysis Of Hydrostatic Pressure Tester

Outdoor sports clothing waterproof test, umbrella test, waterproof fabric test; Jackets, medical protective clothing protective material liquid permeability,

blood permeability test. Dynamic testing, static testing and custom program testing are used to detect the water repellent properties of textiles under a certain pressure.

The sample is fixed in the standard area of the test area, through the air compressor will 0-5bar of air into a water tank filled with distilled water,

the tank connected to the test head, a certain pressure to the sample.

Pressure curve real-time display in the operation screen, built-in various test standards, user-friendly.

Hydrostatic Pressure Tester Testing Principles :

Apply a continuous (dynamic test) or consistent (static test) water pressure to the specimen until the water exudes from the three

different locations of the specimen. After testing at least 3 samples, measure and calculate the average maximum water pressure

(measured in units of mBar or cmH2O), which is the water repellency of the sample.The specific method for the sample is fixed in the standard area of the test area,

the air compressor will 0-5bar of air into a water tank filled with distilled water, a certain pressure of water on the sample.

Tests can be done either by dynamic or static methods.(1) dynamic method: by testing a certain rate of pressure does not contact

with the water side of the sample leakage of fixed water droplets when the pressure to determine the sample of hydrostatic pressure performance.

(2) static method: by testing a certain hydrostatic pressure, the sample to maintain the pressure after a certain period of time to determine the

water permeability of the material to determine the hydrostatic pressure performance.

Hydrostatic Head Test Machine Testing Steps:

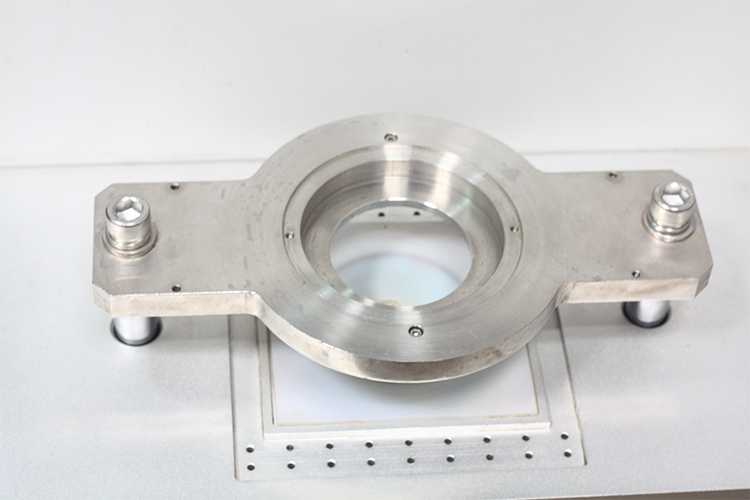

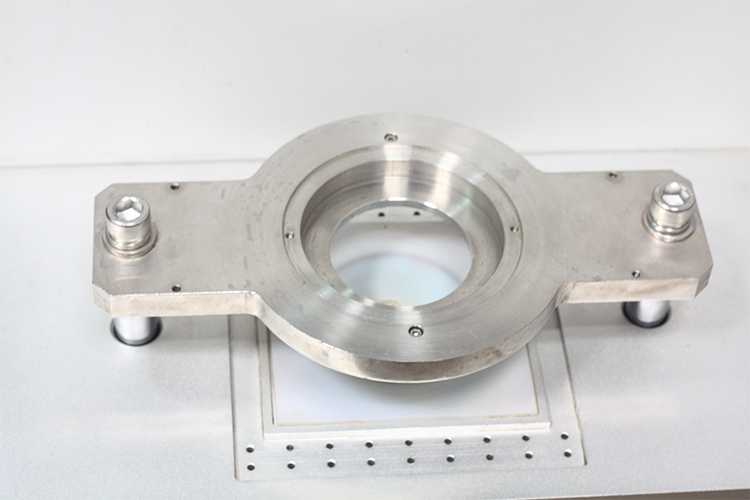

The test fabric cut into 100mm × 100mm size of the sample, and then put the sample into the fixture, tighten the fixture fixed. Press the up button,

the metal container containing 700ml of water starts to rise at the same speed as the motor. The water pressure is increased by the specimen in the fixture.

The color of the paper is measured by the plastic window covering the filter paper. The penetration. When the initial signal indicating the change of the color

of the paper (from blue to pink) appears, the height of the scale is read immediately, expressed in Pa (mmH20), and the rising button is pressed again to stop

the metal container from rising. Record the reading as test data for the impermeability of the filter paper.Open the fixture, remove the sample and indicator paper,

wipe the fixture with a soft cloth, check the water level in the fixture.

If necessary, reinstall the water. Use another sample and indicator paper to place the fixture again and repeat the above test procedure for testing.

If the installation of instructions paper, indicating the preparation of paper can refer to GJB 1152-9l "military efficient air filter paper general specification" of the relevant provisions. 2017-09-06 16:47