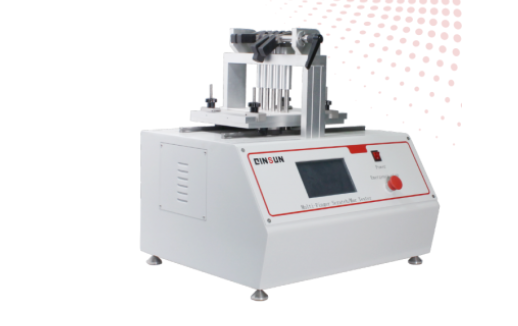

Multi-Finger Scratch/Mar Tester | Automotive Plastics & Interior Materials Testing

The Multi-Finger Scratch/Mar Tester is a high-precision instrument designed for evaluating the scratch and mar resistance of automotive interior materials. It is suitable for plastics, rubber, leather, fabrics, coatings, non-coated substrates, and composite materials. By simulating wear, scraping, and abrasion under controlled conditions, the tester provides repeatable and accurate measurements critical for quality control, research and development, and regulatory compliance.

This tester integrates multi-finger scratching, Burger method, and plastic scraping methods, aligning with standard protocols widely adopted in the automotive industry. Its modular design and adjustable load system ensure flexibility for a wide range of materials and testing standards.

Standards Compliance

North America

GMN 3943-2003: Scratch and Mar Resistance of Plastics, Five Arm Test

FLTM BN 108-13: Resistance to Scratching

STD1024-3113: Automotive Scratch Resistance

GMW 14698-A / GMW 14688: Scratch Resistance of Organic Coatings and Self-Adhesive Foils

Europe

PV3952: Plastic Interior Parts Scratch Resistance Test

BMW GS97034-2, GS97034-9: Scratch Resistance of Interior Materials

Asia / China

GB/T 2918: Plastics Testing

GB/T 6151: Coatings and Plastic Resistance

GB/T 8424.3: Scratch Resistance

OEM-Specific

Chrysler LP-463DD-18-01 / PF-10938

Ford BN 108-13 / BO 162-01

Nissan M0159: Interior Polypropylene Scratch Test

The tester meets over 15 global automotive norms, ensuring broad applicability for OEM and supplier quality control.

Product Advantages

Universal Applicability: Suitable for a wide range of materials including plastics, rubber, leather, fabrics, coatings, and non-composite substrates.

Precision Engineering: High-precision servo motor and ball screw drive system deliver repeatable linear motion and accurate test results.

Modular Flexibility: Interchangeable tungsten carbide scratch heads and adjustable weights (0–100N) accommodate various testing protocols.

Durable Construction: Aluminum and stainless steel body resists corrosion, ideal for long-term lab use.

User-Centric Design: Embedded system with bilingual touchscreen interface (English/Chinese) simplifies operation and data management.

Product Features

Integrated Drive System: Combines drive motor, scraper assembly, and sample fixture for stable, repeatable testing.

Versatile Testing Capabilities: Supports linear motion scratch testing under variable loads (10–200mm/s). Compatible with smooth/textured surfaces, hard coatings, liquid metals, and soft substrates.

Advanced Control System: Embedded automation via 7-inch touchscreen, ensuring ±0.1mm positioning accuracy.

Customizable Test Configurations: Optional multi-finger scratch heads (1mm, 5mm, 10mm) for standardized or custom testing; manual and automatic modes.

Ergonomic Design: Compact footprint (550 × 400 × 300mm), lightweight (28kg), easy to deploy; customizable dimensions available.

Technical Parameters

| Parameter | Specification |

|---|---|

| Test Load Range | 0–100N (adjustable in 1N increments) |

| Scratch Speed | 10–200mm/s (programmable) |

| Scratch Head Options | 1mm, 5mm, 10mm tungsten carbide |

| Power Supply | 220V/50Hz (110V optional) |

| Control Interface | 7-inch color touchscreen (bilingual) |

| Instrument Dimensions | 550mm (L) × 400mm (W) × 300mm (H) |

| Net Weight | 28kg |

| Compliance Standards | Over 15 global automotive norms |

Applications

Automotive interior parts: plastics, leather, fabrics, coatings

Quality control and R&D in automotive manufacturing

Testing OEM-compliant scratch and mar resistance

Surface property assessment for new product verification

FAQ

1. What materials can the Multi-Finger Scratch/Mar Tester evaluate?

It can test automotive plastics, rubber, leather, fabrics, coatings, non-coated substrates, and other composite materials.

2. What makes this tester suitable for automotive industry standards?

It complies with over 15 global norms, including Ford, GM, Chrysler, Nissan, BMW, and PV3952 standards, ensuring results meet OEM requirements.

3. How does the tester achieve repeatable results?

The high-precision servo motor, ball screw drive, and interchangeable tungsten carbide scratch heads ensure uniform linear motion and consistent load application.

4. Can the load and speed be adjusted?

Yes, loads range from 0–100N, and scratch speeds are programmable from 10–200mm/s, suitable for different testing protocols.

5. Is it easy to operate?

Yes, the embedded system with a bilingual touchscreen interface simplifies setup, monitoring, and data logging for global users.

2025-12-08 17:58