-

How does the color matching cabinet work?

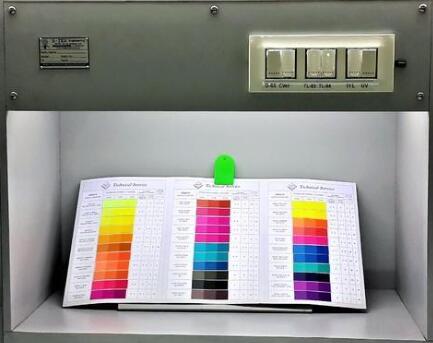

Edited by:Read:The color matching cabinet, also known as a light booth or color assessment cabinet, is a specialized device used to evaluate and compare color samples under standardized lighting conditions. It is commonly employed in industries where accurate color matching is crucial, such as textiles, printing, paint, plastics, and automotive.

The color matching cabinet is a high-quality superior performance color assessment machine. It comes with distinct light sources that mimic various kinds of real-life lighting conditions. When observed under such standard illumination, the user can ensure that one specific color remains the same.

Color matching cabinet is a machine that measures the color variance between two samples. It uses different light types to analyze the color characteristics of specific samples. The cabinet is equipped with five different sources of standard-based lights, including artificial daylight, cool white light, tungsten filament light, ultraviolet black light, and tri-phosphor fluorescent light.

The working principle of a color matching cabinet involves the following key elements:

1. Standardized lighting: The cabinet is equipped with standardized light sources that simulate different types of lighting conditions, such as daylight, incandescent, fluorescent, or specific industry-standard illuminants like D65. These light sources emit specific wavelengths of light to ensure consistent and accurate color perception.

2. Controlled lighting environment: The cabinet is designed to minimize external light interference, providing a controlled environment for color assessment. It typically includes enclosed viewing areas with dark interiors, specialized viewing windows, and light traps to prevent external light from affecting color perception.

3. Sample placement: Color samples, such as fabrics, printed materials, or paint chips, are placed inside the cabinet for evaluation. Multiple samples can be examined simultaneously for visual comparison and color matching.

4. Standardized color assessment: By illuminating the samples with the standardized light sources, the cabinet allows users to assess color appearance and evaluate color differences accurately. This ensures consistency in color perception across different lighting conditions, minimizing the influence of ambient lighting on color assessment.

5. Color evaluation and analysis: Users visually evaluate the color samples inside the cabinet, comparing them against reference standards or other samples for color matching purposes. Color metrics, such as CIE L*a*b* values, can be measured using color measurement instruments, such as spectrophotometers, to provide objective color data for analysis.

By using a color matching cabinet, companies can ensure consistent and accurate color assessment, enabling them to make informed decisions regarding color quality, consistency, and reproducibility in their products. This is particularly important when dealing with materials that will be viewed under different lighting conditions, ensuring that colors appear as intended and meet customer expectations.

- 2024-04-19Paper ring compression strength tester standards

- 2024-04-19Cupping tester standards

- 2024-04-19Rubber and plastic tensile tester standards

- 2024-04-19Taber 1750 wear-resistant tester standards

- 2024-04-19Stone Chip Resistance Gravelometer standards

- 2024-04-18Diaper absorption speed tester standards

- 2024-04-18Diaper leakage tester technical indicators

- 2024-04-18Paint film impact resistance tester standards

- 2024-04-18Low temperature brittleness tester principle

- 2024-04-18Battery separator permeability tester technical indicators