-

What is tensile strength testing?

Edited by:Read:Tensile strength testing is a mechanical testing method used to determine the maximum load or force a material can withstand before breaking, also known as its tensile strength. This testing method is essential in various industries such as construction, automotive, aerospace, and manufacturing to evaluate the performance and suitability of materials under tensile stress, which is the force that pulls the material apart.

Tensile strength testing typically involves the following steps:

1. **Sample preparation**:

Test specimens, usually in the form of a flat or cylindrical shape, are prepared according to standardized dimensions and specifications.

2. **Testing equipment**:

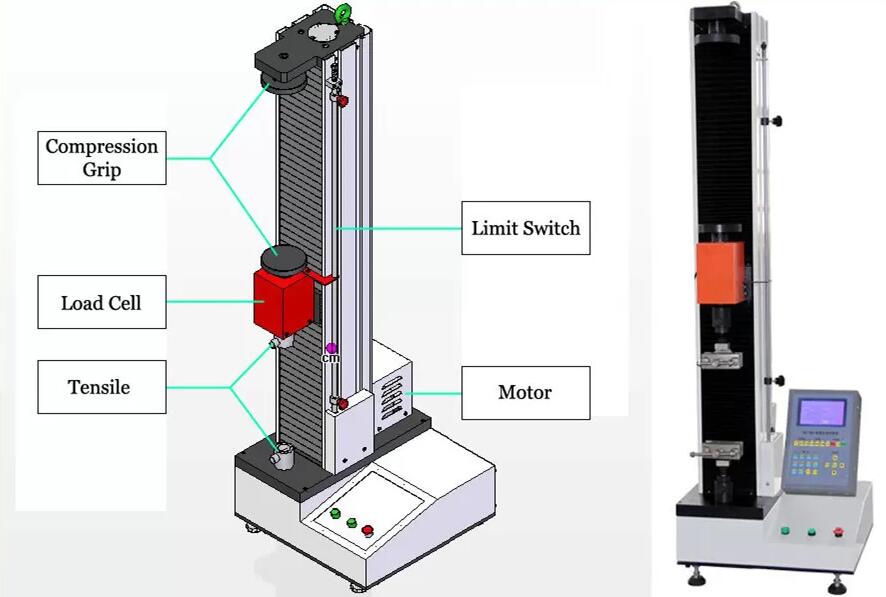

A tensile testing machine is used for the test. This machine has a load cell for measuring the applied force and an extensometer for measuring the elongation or changes in the specimen's length.

3. **Test procedure**:

The specimen is placed between the grips of the tensile testing machine, which then applies a steadily increasing load or force along the specimen's longitudinal axis. The load and elongation are continuously recorded during the test.

4. **Specimen failure**:

The test continues until the specimen breaks or fails. The breaking point is characterized by a sudden drop in the applied force.

5. **Data analysis**:

The collected data is analyzed to determine the tensile strength, yield strength, elongation, and other material properties related to tensile stress.

The tensile strength is typically reported in units of force per unit area, such as megapascals (MPa) or pounds per square inch (psi). The result is used to compare the performance of different materials, assess their suitability for specific applications, and ensure that they meet the required quality and safety standards.

- 2024-04-19Paper ring compression strength tester standards

- 2024-04-19Cupping tester standards

- 2024-04-19Rubber and plastic tensile tester standards

- 2024-04-19Taber 1750 wear-resistant tester standards

- 2024-04-19Stone Chip Resistance Gravelometer standards

- 2024-04-18Diaper absorption speed tester standards

- 2024-04-18Diaper leakage tester technical indicators

- 2024-04-18Paint film impact resistance tester standards

- 2024-04-18Low temperature brittleness tester principle

- 2024-04-18Battery separator permeability tester technical indicators