-

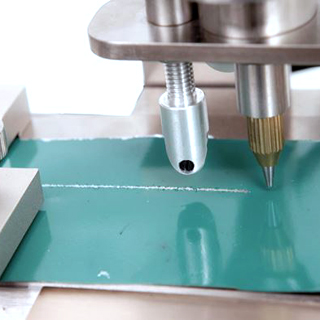

Investigating Material Durability with Multi-Finger Scratch Tester

Edited by:Read:Multi-Finger Scratch Tester is a device for testing the durability of materials. It can simulate scratches in various real-world environments to evaluate the service life and durability of materials.

The steps to use the Multi-Finger Scratch Tester to study material durability are as follows:

1. Prepare samples: select the material to be tested and prepare it according to the size and shape of the standard sample.

2. Adjust test parameters: Set test parameters, such as load, speed, test time, etc., according to test requirements and material characteristics.

3. Conduct the test: place the sample on the test bench, start the test instrument, and perform the multi-finger scratch test. During the test, the testing instrument will simulate different scratch situations, and record the depth, length, position and other information of each scratch.

4. Analyze the test results: According to the test results, analyze the durability and service life of the material. The optimal material can be selected by comparing the test results of different samples.

5. Optimize material performance: According to the test results, optimize the performance of the material to improve its durability and service life. It can be optimized by changing the material composition, processing technology, etc.

Using the Multi-Finger Scratch Tester to study material durability can help manufacturers choose the best materials and optimize their performance to improve product quality and life. At the same time, various materials can also be scientifically evaluated to provide a reference for material research and development.

- 2024-04-19Paper ring compression strength tester standards

- 2024-04-19Cupping tester standards

- 2024-04-19Rubber and plastic tensile tester standards

- 2024-04-19Taber 1750 wear-resistant tester standards

- 2024-04-19Stone Chip Resistance Gravelometer standards

- 2024-04-18Diaper absorption speed tester standards

- 2024-04-18Diaper leakage tester technical indicators

- 2024-04-18Paint film impact resistance tester standards

- 2024-04-18Low temperature brittleness tester principle

- 2024-04-18Battery separator permeability tester technical indicators