-

5 best guidelines for maintaining Fiber Microtome

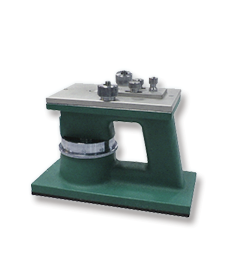

Edited by:Read:The Fiber Microtome is a common machine for manufacturing pulp, and is especially essential in the field of pulp manufacturing. It can cut raw materials such as textiles, cotton, wood, grassland, and cardboard into various reasonable lengths and widths for subsequent processing. However, as the Fiber Microtome is used for longer and longer periods of time, various problems often arise, which may even force the machine to be scrapped. In order to prolong the service life of Fiber Microtome and reduce losses, the following will introduce how to maintain Fiber Microtome:

1. Regular maintenance

Fiber Microtome is like other machines, regular maintenance can extend the service life of the machine. Clean the blades, oil pump, sprockets and other components, clean up the dust and impurities accumulated inside the equipment. Special attention should be paid to cleaning the blade, the cutting knife is the core component of Fiber Microtome, only to ensure the sharpness and neatness of the blade to ensure its cutting effect and production efficiency.

2. Apply professional maintenance experience

Although Fiber Microtome is relatively simple compared with other machines, but maintenance requires practical experience, equipment maintenance personnel must have a wealth of maintenance skills. Some machine malfunctions become more and more serious due to improper handling, and improper use can cause inefficient machine operation, resulting in unnecessary losses, therefore, it is sometimes recommended that users seek professional mechanical maintenance personnel directly.

3. Customized operating procedures

A Fiber Microtome has different usage environment and operation practices in different factories. In order to ensure the stability and safety of the machine, you need to customize your own operating procedures. In order to achieve this, it is necessary to first establish the operating standards and equipment maintenance procedures suitable for your own unit, analyze the failure points of your own machine, and try to put together disposal plans for use according to the problems that arise.

4. Tabulated records

Fiber Microtome maintenance should be fully documented and a detailed and comprehensive ledger record should be created. According to the machine statute dynamic operation of the specific circumstances, both to visualize the maintenance of the machine, but also for the use of the process to improve the record of the view and reference to provide the basis.

5. with good accessories

The quality of raw materials and accessories plays a decisive role in maintaining and using the machine correctly. In the process of equipment repair, replacement parts should only be of good quality to give impetus to machine maintenance. It is also necessary to pay attention to the placement and timely replacement of accessories in order to keep the Fiber Microtome in ideal operating condition for a long time.

In short, these five points are very important ways to maintain Fiber Microtome, and we hope they will help Fiber Microtome maintenance to improve the efficiency of the machine, reduce the loss and extend the life of the machine.

- 2024-04-19Paper ring compression strength tester standards

- 2024-04-19Cupping tester standards

- 2024-04-19Rubber and plastic tensile tester standards

- 2024-04-19Taber 1750 wear-resistant tester standards

- 2024-04-19Stone Chip Resistance Gravelometer standards

- 2024-04-18Diaper absorption speed tester standards

- 2024-04-18Diaper leakage tester technical indicators

- 2024-04-18Paint film impact resistance tester standards

- 2024-04-18Low temperature brittleness tester principle

- 2024-04-18Battery separator permeability tester technical indicators