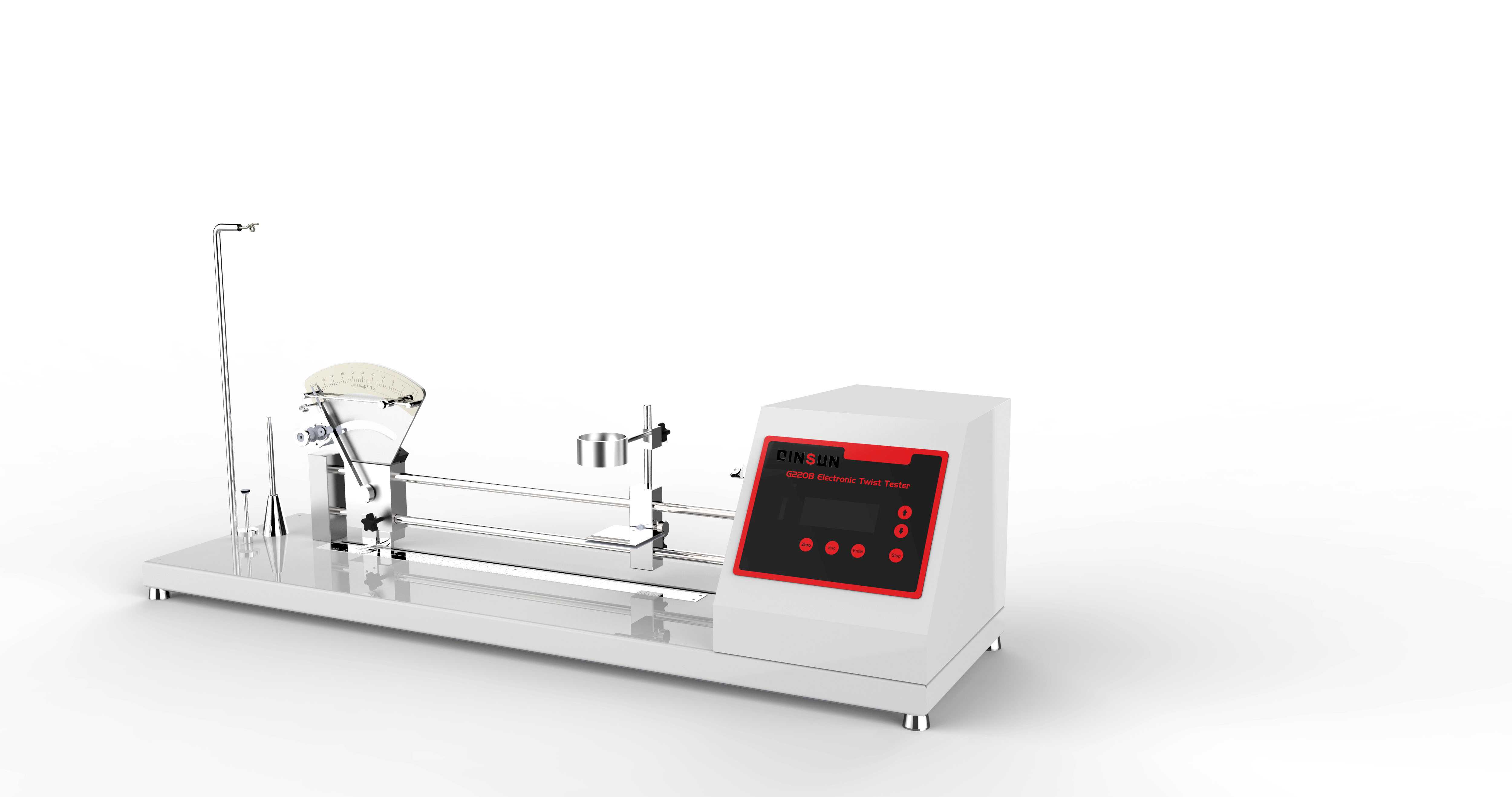

Introduction of Electronic Twist Tester

Electronic Twist Tester (also commonly known as Electronic Torsion Testing Machine) is a material testing machine controlled by electronic technology, primarily used for testing the torsional mechanical properties of materials. Below is a detailed introduction to several aspects of the Electronic Twist Tester Machine:

Applicable Standards

ASTM D1422/1423,BS 2085,DIN 53832,ISO 2061,IWTO 25-70,GB/T 2543.1-2001/2543.2-2001

Main Functions and Applications

The Electronic Twist Tester Machine is capable of testing various parameters such as torsional strength, torsional stiffness, and torsional deformation of materials, applicable to a wide range of materials including metals, plastics, rubbers, springs, wires, and more. In the fields of preventive medicine and public health, it can be used to test the mechanical properties of bones and metallic implant materials; in industrial manufacturing, it serves as a crucial tool for quality control and product development, enhancing product reliability and market competitiveness; in materials science research, by simulating mechanical effects under different conditions, researchers can gain deeper insights into the relationship between the microstructure and macroscopic properties of materials.

Structure and Composition

The Electronic Twist Testing Machine typically consists of a main unit, clamping fixtures, sensors, control systems, and other components.

Main Unit: Adopting a horizontal structure, the main body is constructed with thickened steel plates to ensure the rigidity of the entire machine. The clamping fixtures are made of high-quality alloy steel, offering long service life and convenient, quick installation and removal of samples.

Drive System: Utilizing a fully digital control system, it provides adjustable speed regulation for uniform and stable loading.

Transmission System: Employing a precision reducer, it ensures uniform, stable transmission and high precision.

Measurement and Display System: A large-screen LCD system is used to synchronously display parameters such as torque, torsion angle, and test speed of the sample.

Working Principle

The working principle of the Electronic Twist Testing Machine involves electric loading to move the sensor and sensor support for easy sample clamping. During torsional loading, the fully digital AC servo system drives the precision planetary gear reducer, which rotates the clamping fixture to apply load to the specimen, achieving the torsional test. During the test, manual left and right rotation operations can be performed.

Operation and Test Procedure

Preparing Samples: According to testing standards, prepare samples of appropriate size and shape, ensuring they are flawless and representative of the material's overall performance.

Installing Samples: Clamp the sample in the machine's clamping fixture, ensuring it remains straight and without significant stress concentration during tension.

Setting Parameters: Based on testing standards or actual requirements, set the machine's parameters, such as torsional speed and torque range.

Starting the Test: Initiate the machine to begin applying gradually increasing torque. Observe the torsional process of the sample until it breaks or reaches the predetermined test conditions.

Recording Data: Automatically or manually record data during the test, including torque-torsion angle curves, maximum torque, yield torque, and more.

Analyzing Data: Analyze and process the collected data to assess the material's torsional mechanical properties.

Technical Characteristics and Advantages

High Precision: Utilizing high-precision sensors and measurement systems to ensure test results' accuracy.

Multifunctionality: Capable of setting multiple test parameters and modes to meet the testing needs of different materials.

Ease of Operation: Featuring a user-friendly interface and operational flow, facilitating user operation and use.

Safety and Reliability: Employing multiple safety protection measures to ensure safety and reliability during testing.

Qinsun Instruments Co., LTD, established in 2012, focuses on the research and development, design, and production of textile testing instruments. It provides textile testing instruments and services to academic research units and testing institutions. Qinsun is currently one of the most competitive and R&D-capable manufacturers of textile testing instruments in China, with an R&D team composed of experienced engineers. We are dedicated to serving our customers with all our hearts and striving to promote technological innovation in textile testing instruments.

2025-01-09 10:01