6 Important Features of Warming Dummies

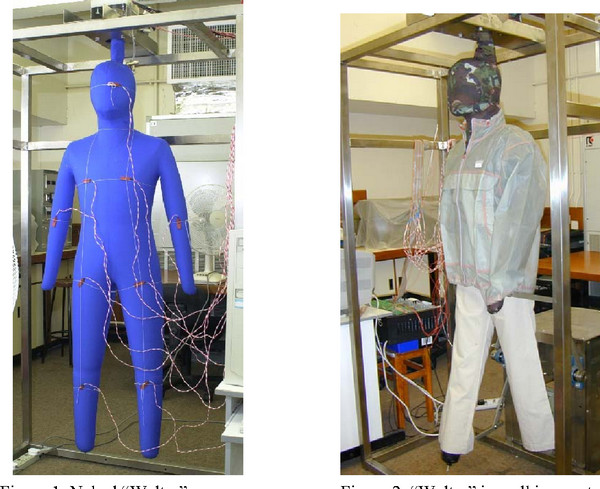

The warm body dummy model can test the detailed data system. The dummy itself has no higher strength. A nearly 700m pure nickel wire is placed in the dummy from the fingers to the nasal cavity. Smart circuits ensure the accuracy of the measurement process. .The circuit inside each part ensures the accuracy of measurement, and the built-in heat conduction system can ensure good uniformity. At the same time, the dummy can be divided into two parts for easy transportation. I will explain from two perspectives.

The main features of the thermal dummy:

1. The human body model is divided into 17 anatomical parts such as head, torso, and limbs. Each section has adiabatic and fine-tuned heaters in each section. Constant power control can realize surface heating and constant temperature control;

2. In the control software, various measurement data, recording and statistical processing can be processed for the internal heat of the human body model, the thermal insulation performance of clothing, the evaluation of the surface temperature of the human body model, and the calculation of heat dissipation and calorific value;

3. The resin with small heat capacity is used when making the human body model, which can quickly handle the thermal reaction and heat exchange process of the human body model;

4. Thermal nickel wire sensor, connected with the whole system, can measure the average temperature of each section, with good sensitivity;

5. The joints, shoulders and knees can be bent and can be transformed into standing or sitting positions, which is convenient for undressing;

6. The mannequin standard lift frame, which can easily move the mannequin.

The main application of the thermal dummy:

In the hazardous environment of fire, people need to wear thermal protective clothing to avoid fire damage. Thermal protective clothing is used to protect firefighters, steelworkers and other workers who work in hot and hazardous locations. With the increase of clothing exposure time in the flame, the surface temperature of the clothing will gradually increase due to the direct combustion of the flame, and a large amount of heat transfer causes the air layer under the clothing and the surface temperature to increase at the same time as the human body. Not only will the thermal physical properties of the fabric itself change when the garment is burned by flames, affecting its thermal protection performance, but also the surface temperature of the garment will remain within a high range after leaving the flash fire environment. , and will come into contact with the clothing underneath. The temperature difference is formed with the surface temperature of the human body, and the continuous heat transfer makes the surface temperature of the human body rise continuously.

Research has shown that burns can occur after a flash fire is over, and the energy stored in the fabric is also an important factor in predicting burns. Therefore, even if the thermal protective clothing can withstand a short period of flame burning, it can still cause scalding during the cooling process. Therefore, it is particularly important to study the changes in the surface temperature of clothing and human body after combustion. Research on multi-layer protective clothing using thermal dummies shows that the outer fabric has an important influence on the protective performance of multi-layer protective clothing.

Tests using the TPP instrument found that long-term exposure to a heat source with low heat flux was more likely to cause burns than short-term intense burns. In the actual wearing process, the thermal insulation performance of clothing not only depends on the performance of the fabric itself, but also needs to be comprehensively considered from the aspects of clothing style design, specifications, and wearing posture. In order to simulate the situation of the human body in the actual fire field as realistically as possible, and to determine the surface temperature of the clothing and the human body safely and accurately, the test method of the thermal dummy has shown its advantages and has been widely used and verified. Used in the field of thermal protection.

QINSUN is committed to providing laboratory testing equipment and equipment solutions for the textile industry and environmental protection industry in China. The Walter Sweating Fabric Manikin developed by QINSUN and the University of Hong Kong has won a very good reputation among customers. Interested friends are welcome to order!

2022-05-05 09:54