ASTM D3511 Brush-Type Pilling and Fuzzing Tester

The ASTM D3511 Brush-Type Pilling and Fuzzing Tester is designed to evaluate the pilling and fuzzing performance of textiles under controlled friction and abrasion conditions. It is widely used for apparel, home textiles, and automotive interior materials. The tester ensures fabrics meet strict quality standards by simulating wear and providing objective pilling ratings through comparison with standard reference cards.

Application

(1) Assessment of pilling and fuzzing resistance for woven and knitted fabrics.

(2) Quality control in apparel, home textiles, and automotive interior manufacturing.

(3) Evaluation of surface treatments or finishes aimed at improving anti-pilling performance.

(4) Standardized testing for new material development and supplier verification.

Standards

(1) ASTM D3511 — Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Brush Method

(2) FORD BN-108-03 — Fabric Pilling Test Standard for Automotive Applications

(3) GM 9652P — General Motors Fabric Pilling Test Standard

Features

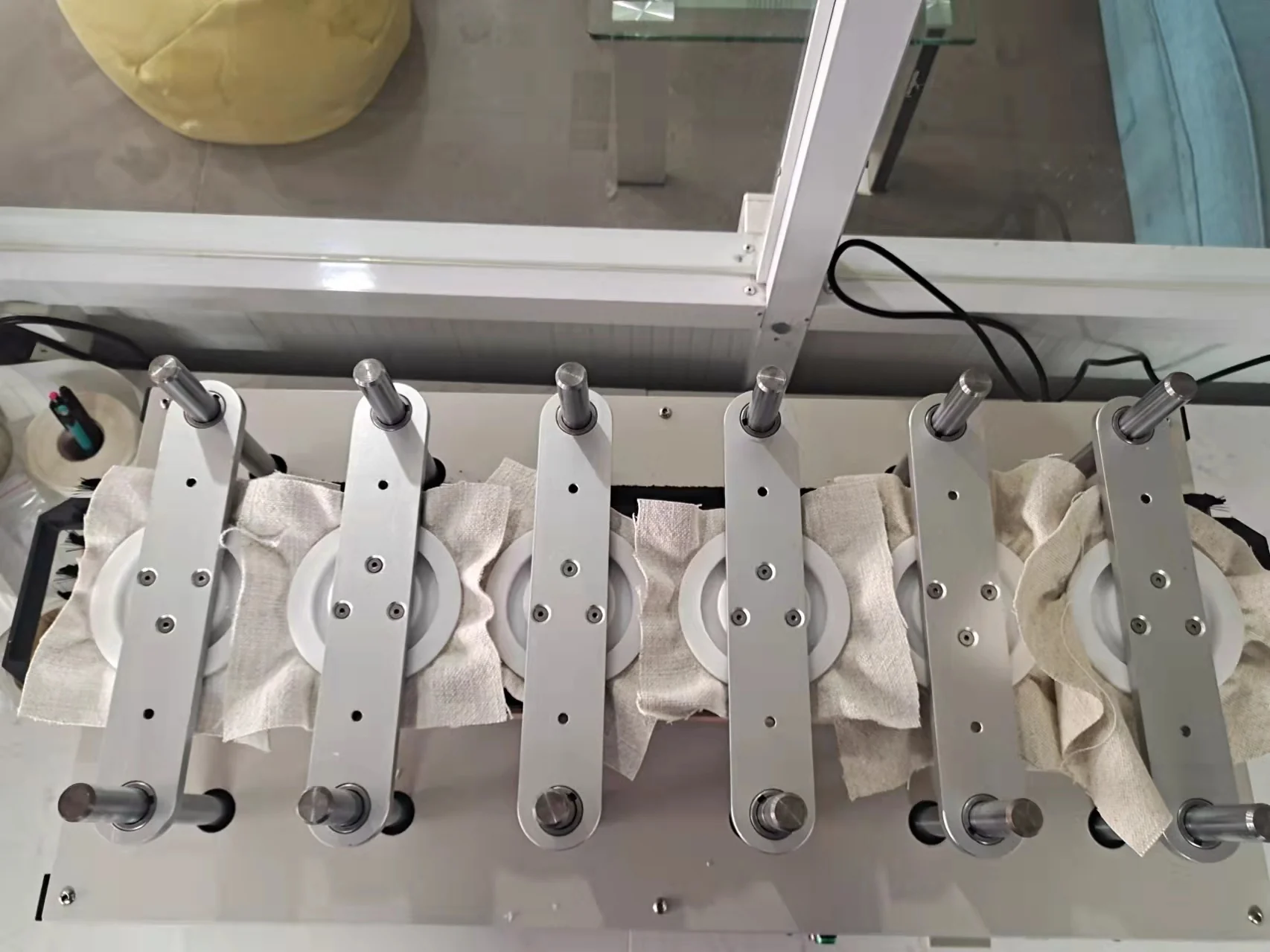

Brush-type tester with circular sample clamps and polyurethane foam surface for realistic wear simulation.

Adjustable rotation speed for controlled friction cycles.

Equipped with pilling rating viewer for comparison with standard reference cards.

High reproducibility of test results for both woven and knitted fabrics.

Compact design with electronic counter for precise cycle recording.

Parameters

| Parameter | Specification |

|---|---|

| Sample Clamp Type | Circular, 660 g, soft foam rubber surface |

| Pilling Amplitude | 19 mm |

| Nylon Brush Height | 25.4 mm |

| Sample Configuration | 6 clamps per test, rubber edge clamp, sandpaper backing |

| Rotation Speed | 58 r/min |

| Sponge Block Size | 51 × 102 × 152 mm |

| Rotation Counter | Electronic, up to 999,999 cycles |

| Power Supply | 220 V / 50 Hz |

| Dimensions (L×W×H) | 914 × 305 × 381 mm |

FAQ

(1) What is this product?

A brush-type pilling and fuzzing tester designed to evaluate the durability and surface appearance of fabrics under friction.

(2) What is it used for?

To assess pilling and fuzzing resistance of woven and knitted fabrics and ensure compliance with international standards.

(3) Why is it important?

Helps manufacturers guarantee product quality, maintain consistent appearance, and validate the effectiveness of anti-pilling treatments.

(4) What problems does it solve for users?

Provides objective, reproducible ratings for pilling and fuzzing, preventing quality issues before the product reaches consumers.

(5) What types of fabrics can be tested?

Woven fabrics, knitted fabrics, and blends commonly used in apparel, home textiles, and automotive interiors.

(6) How is the test performed?

Fabric samples are mounted on clamps with a polyurethane foam surface. Nylon brushes simulate wear while the sample rotates at a controlled speed. After a specified number of cycles, pilling and fuzz formation are rated using a reference card under standardized lighting.

Leave Message Get Price