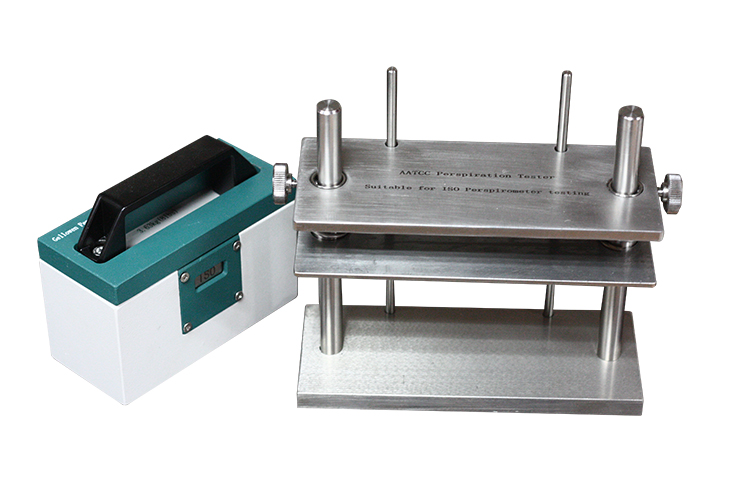

Perspiration Color Fastness Tester

The Perspiration Color Fastness Tester is designed for evaluating the resistance of textiles to various perspiration conditions. It determines the effect of acidic or alkaline sweat, seawater, saliva, and distilled water on the color fastness of textile materials. The instrument combines the test specimen with specified adjacent fabrics, applies test solutions, and applies controlled pressure for a fixed duration. After treatment, specimens and adjacent fabrics are dried and assessed for color change and staining. The tester is compatible with AATCC and ISO chemical reagent sets and can hold multiple specimens simultaneously.

Applications

(1) Testing the color fastness of woven fabrics, knitted fabrics, yarns, nonwovens, dyed or printed textiles, finished garments, home textiles, automotive interior textiles, and protective textiles.

(2) Evaluating textiles exposed to acidic and alkaline perspiration, seawater, saliva, and distilled water.

(3) Quality control in textile manufacturing, research institutes, and third-party testing laboratories.

(4) Pre-production testing of textiles in laboratories or on-site inspection for functional performance.

Standards

(1) ISO 105-E01: Textiles — Tests for colour fastness — Part E01: Colour fastness to water

(2) ISO 105-E02: Textiles — Tests for colour fastness — Part E02: Colour fastness to acidic and alkaline perspiration

(3) ISO 105-E04: Textiles — Tests for colour fastness — Part E04: Colour fastness to artificial perspiration

(4) DIN EN ISO 105-E01/E02/E04: Leather and textiles — Colour fastness testing to perspiration

(5) AATCC 15: Colorfastness to Perspiration

(6) AATCC 106/107: Colorfastness to Acidic and Alkaline Perspiration

(7) BS 1006: British Standard: Textiles — Colour fastness to perspiration

(8) DIN 54005: German Standard for color fastness to perspiration

(9) M&S C6/C7: Marks & Spencer Standard Methods for color fastness to perspiration

(10) NEXT TM4: Next Standard for color fastness to perspiration

(11) GB/T 3992: Textile — Colour fastness to perspiration

(12) GB/T 5713/5714: Textile — Colour fastness of dyed textiles to artificial perspiration

Features

(1) Stainless steel specimen frame capable of holding up to 20 specimens.

(2) Acrylic separation plates placed between each specimen for uniform pressure distribution.

(3) Standard weights supplied according to AATCC, ISO, and BS methods to avoid incorrect loading.

(4) Compatible with perspiration fastness ovens for controlled drying.

(5) Suitable for a wide range of textile types, including functional and protective materials.

(6) Can be used with complete chemical reagent sets meeting AATCC and ISO standards.

(7) Simple operation, robust construction, and reliable test results.

Technical Parameters

| Item | Specification |

|---|---|

| Specimen Frame | Stainless steel, 1 set |

| Specimen Capacity | 20 specimens |

| Specimen Size | 100 mm × 40 mm |

| Separation Plates | Acrylic, 21 pcs |

| Standard Weights | 2 sets (AATCC / ISO / BS compliant) |

| Load Identification | Different weights correspond to different test standards |

| Test Media | Acidic/alkaline perspiration, seawater, saliva, distilled water |

| Accessories Compatibility | Perspiration fastness oven, chemical reagent set |

FAQ

(1) What is the main purpose of this tester?

It evaluates the color fastness of textiles under perspiration, seawater, saliva, and distilled water exposure.

(2) What types of textiles can be tested?

Woven fabrics, knitted fabrics, yarns, nonwovens, dyed and printed textiles, and finished textile products.

(3) Which international standards are supported?

ISO, AATCC, BS, DIN, M&S, NEXT, and relevant GB/T standards with full test names.

(4) How many specimens can be tested at one time?

Up to 20 specimens can be tested simultaneously.

(5) Why are different standard weights provided?

Different weights correspond to different test standards, preventing incorrect loading conditions.

(6) Is an oven required for testing?

Yes, a perspiration color fastness oven is required for controlled drying and conditioning.

(7) Are chemical reagents included?

A complete reagent set suitable for AATCC and ISO methods can be supplied; hazardous liquids are recommended for local purchase.

(8) Who typically uses this equipment?

Textile testing laboratories, quality inspection agencies, research institutes, and textile manufacturing enterprises.

Leave Message Get Price